Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Introducing, Swords Precision's Metal Hardware CNC M35 Turning 5 Axis Service Part Brass. This custom bicycle machining mold service is perfect for all your metal hardware needs.

Our experienced team of manufacturers use top-of-the-line CNC technology to create precise and intricate parts. The M35 turning 5 axis service ensures that each piece is crafted with the utmost accuracy and attention to detail. Whether you need a small part or a large component, Swords Precision has you covered.

We specialize in brass manufacturing, a durable and versatile material perfect for a wide range of applications. From bike parts to industrial hardware, our brass components are built to last.

At Swords Precision, we understand that every project is unique. That's why we offer custom machining services to meet your specific needs. Our team will work with you to create a design that fits your exact specifications.

When it comes to quality, reliability, and precision, Swords Precision is the name you can trust. Our metal hardware CNC services are unmatched in the industry, and we take pride in every piece we create.

Don't settle for subpar products when you can have the best. Choose Swords Precision for all your metal hardware needs. Contact us today to learn more about our custom bicycle machining mold services and see how we can help bring your project to life

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy.

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, 3D Printing, Rapid Prototype, Moulds etc |

|||||||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

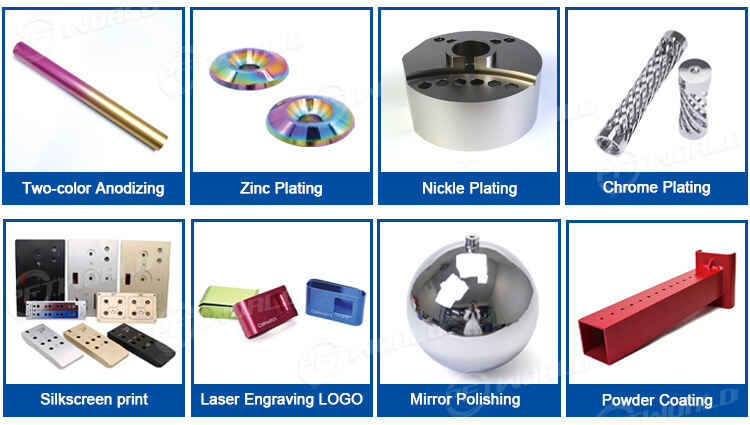

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

+/-0.01 ~ 0.005mm |

|||||||

Surface Roughness |

Min Ra 0.1~3.2

|

|||||||

CERTIFICATE |

||||||||

1. Are you a manufacturer or a trading company

We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports

2. How to get a quote3. Can I get a quotation without drawings

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation

4. Can you provide samples before mass production

Of course, the sample fee is necessary. If possible, it will be returned during mass production

5. What is the delivery date

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks

6. How do you control quality

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog