Edifício 49, Parque Industrial Fumin, Vilarejo de Pinghu, Distrito de Longgang

Domingo Fechado

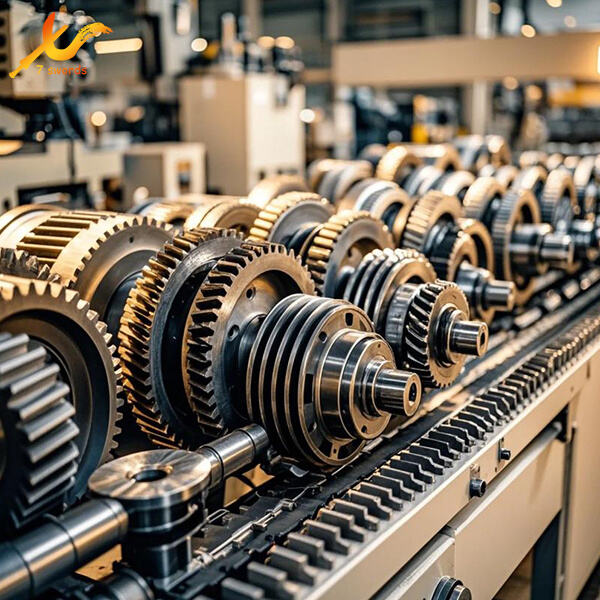

A produção de engrenagens é um trabalho muito importante que contribui para a fabricação de máquinas e diversos produtos. Peças de precisão aeroespacial são empresas especializadas que lidam com a fabricação de engrenagens para organizações que as necessitam e as utilizam como parte de seus próprios produtos. Um nome consolidado nesse setor é Swords Precision. Eles são um dos principais fabricantes de engrenagens OEM que produzem engrenagens para diferentes indústrias em todo o mundo. Este artigo discute fabricantes de caixas de engrenagens OEM, como eles apoiam as cadeias de suprimentos e novas inovações, benefícios de se associar a um fornecedor OEM e tendências atuais dentro da indústria.

OEM é a sigla para original equipment manufacturer (fabricante de equipamentos originais). Isso implica que esses fabricantes produzem engrenagens para outra empresa que as utiliza em seus produtos. Por exemplo, a Swords Precision se associa a outros fabricantes para desenvolver produtos que atendem aos seus requisitos de fabricação únicos. Eles fazem isso por meio do engenhamento e criação de engrenagens sob medida para atender às necessidades de cada cliente. Dessa forma, as engrenagens são fabricadas exatamente para funcionar com os produtos que eles produzem.

Gestão da Cadeia de Suprimentos, quais são as etapas anteriores para que os produtos percorram o caminho da sua imaginação até as mãos dos clientes. Nas cadeias de suprimentos, Peças CNC de Alumínio desenvolver peças centrais que outras empresas precisam para fabricar produtos. Para dar um exemplo, se um fabricante deseja construir uma nova máquina, ele precisará de engrenagens para o funcionamento suave da máquina. Essas engrenagens são fabricadas por fabricantes OEM, como a Swords Precision. A Swords Precision faz com que toda a cadeia de suprimentos funcione melhor, garantindo engrenagens de alta qualidade e muito precisas. Isso significa que os produtos podem ser fabricados em minutos, em vez de horas ou até dias, e então enviados aos clientes de forma pontual.

Ideias novas ou inovação é crucial para qualquer organização que deseja permanecer relevante e bem-sucedida como líder de mercado em sua indústria. Por outro lado, fabricantes de equipamentos OEM ajudam na inovação colaborando com outros fabricantes para projetar e produzir engrenagens personalizadas que atendem às suas especificações de produto. A Swords Precision possui uma equipe competente de engenheiros e designers como seu núcleo de especialização. Essas engrenagens também são muito importantes para o desempenho dos itens que as utilizam, então eles podem fabricar ótimas engrenagens. E uma máquina bem lubrificada produz produtos melhores e clientes mais felizes que estão mais satisfeitos com suas compras.

Todas essas são razões válidas pelas quais uma empresa deve procurar os serviços de um fabricante de engrenagens OEM. As vantagens incluem economia de custos, produtos de melhor qualidade, tempos de produção mais rápidos e acesso a expertise. Por essa razão, empresas que colaboram com fabricantes de engrenagens OEM, como a Swords Precision, podem se beneficiar de todas as tecnologias e inovações de ponta aproveitando seus produtos no mercado. Além disso, com ajuda especializada, os fabricantes também minimizam o risco de erros ou defeitos em seus produtos. Isso ocorre porque erros podem levar a recall caros e, além disso, pode manchar rapidamente o nome de uma empresa ou empresa.

A indústria de fabricação de engrenagens é uma área em constante evolução, e os fabricantes de engrenagens OEM não são diferentes. A tecnologia de impressão 3D é uma das tendências atuais no setor. Nos dias de hoje, muitos fabricantes de engrenagens OEM estão utilizando a impressão 3D para desenvolver protótipos ou modelos de produtos que podem ser testados antes de realmente serem produzidos. Ao comprovar essa metodologia, isso reduziu significativamente os custos associados à prototipagem e conseguiu diminuir consideravelmente o tempo de entrega dos protótipos. A popularidade dos lubrificantes sintéticos é uma tendência adicional e mais comum. Esses lubrificantes estão sendo utilizados com mais frequência devido ao fato de oferecerem um desempenho aprimorado, além de uma pegada ambiental reduzida em comparação com lubrificantes tradicionais.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Todos os direitos reservados — Política de privacidade—Blog