Edifício 49, Parque Industrial Fumin, Vilarejo de Pinghu, Distrito de Longgang

Domingo Fechado

Você já se perguntou como produtos de plástico, como seus brinquedos favoritos ou copos, são produzidos? Talvez você tenha um brinquedo de plástico ou até um copo de plástico em casa que você adora. E essas coisas de plástico são feitas através de um processo chamado moldagem por injeção. Passo a passo, vamos navegar por esse processo.

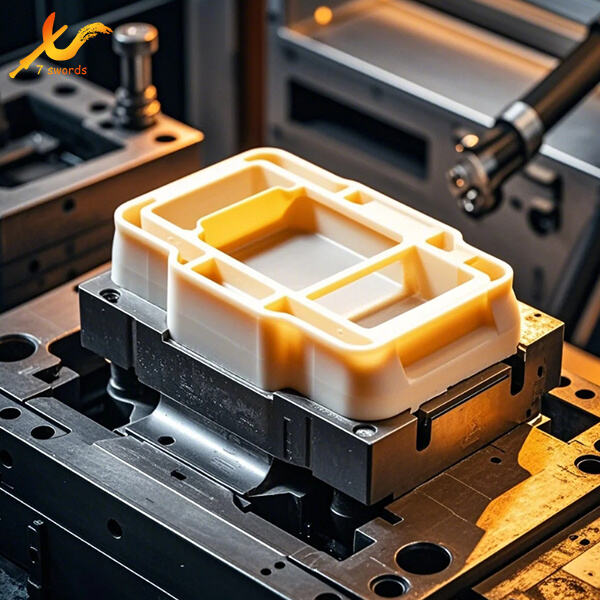

A moldagem por injeção é um método altamente fascinante para produzir itens poliméricos. O processo começa ao derreter o plástico, transformando-o em um líquido viscoso pegajoso. O plástico derretido é então injetado em um objeto metálico com formato de entupimento chamado molde. A forma como você deve pensar no molde é semelhante a um cortador de biscoitos, mas em vez de biscoitos, ele faz alguns tipos de formas de plástico! O molde é preenchido com o plástico fundido, e quando esfria, ele endurece e adota a forma do molde. O plástico é então deixado esfriar e endurecer no molde antes de removê-lo (voilá!) Seu artefato de plástico está pronto e preparado para uso!

Ao usar injeção de moldagem para criar objetos plásticos, existem várias considerações importantes que devem ser feitas. O primeiro passo é escolher o tipo correto de plástico para o objeto projetado. Basicamente, isso importa porque vários tipos de plástico se comportam de maneira diferente quando são derretidos e resfriados. Alguns tipos de plástico vão derreter mais rapidamente do que outros. Depois disso, você precisa escolher a temperatura e pressão adequadas para o plástico quando ele derreter. Isso ajuda a preencher a forma do plástico dentro do molde exatamente, para que o objeto externo saia corretamente. E por último, o design do próprio molde também é muito importante. Você deve determinar o tamanho do molde, seu design e quantas peças deseja produzir de uma só vez. Todas essas são boas escolhas para fornecer um objeto de alta qualidade e visualmente atraente!

O processo de moldagem por injeção requer uma etapa importante que se refere ao controle de qualidade. Ou seja, garantir a fabricação correta de todos os produtos plásticos envolvidos e sua segurança para continuar em uso. É por isso que a qualidade é algo que a Swords Precision leva extremamente a sério. Existem vários métodos que empregamos para verificar a qualidade de nossos produtos. Uma etapa, por exemplo, é que verificamos visualmente cada objeto para ver se há algum erro ou não. Também verificamos seu tamanho, para que estejam dentro da faixa adequada. Além disso, realizamos testes em alguns itens para verificar que eles funcionarão corretamente. Tudo isso nos guia para garantir que tudo o que produzimos esteja em conformidade com os requisitos que nossos clientes demandam. Mantemos nosso local de trabalho organizado para garantir a segurança e a qualidade.

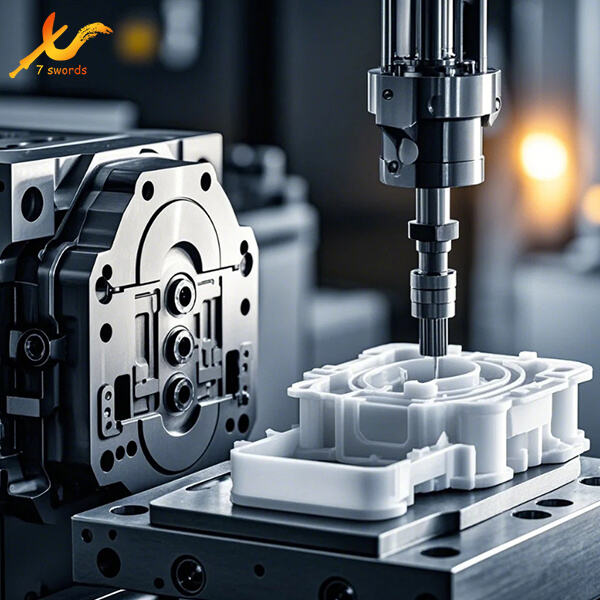

Swords Precision utiliza métodos avançados de moldagem por injeção que nos ajudam a acelerar nosso processo e desenvolver produtos superiores. Essas técnicas incluem automação, que essencialmente é o uso de máquinas capazes de realizar uma tarefa sozinhas, sem necessidade de intervenção humana. Isso nos ajuda a concluir o trabalho rapidamente e com precisão, reduzindo o ciclo de erros enquanto aumenta a produtividade. Também temos robôs para nos auxiliar em tarefas árduas e complexas, onde é necessário extrema precisão e repetição frequente. Os robôs são capazes de executar essas tarefas de maneira que garanta que tudo seja feito perfeitamente. Também utilizamos CAD/CAM (desenho assistido por computador e fabricação assistida por computador). Essa tecnologia nos permite projetar e fabricar objetos com excelente precisão, um requisito crucial para produtos de qualidade.

Swords Precision sabe que cada cliente terá um tipo específico de necessidade ao procurar a produção de plástico. Esse é precisamente o nosso serviço de moldagem por injeção de plástico personalizado. Isso significa que podemos fabricar cada componente de acordo com as especificações do cliente. Cada item é elaborado seguindo os mais altos padrões de qualidade, enquanto nossos engenheiros e designers talentosos trabalham de perto com cada cliente. Detalhes como resistência e desempenho nunca são negligenciados durante o processo de fabricação, garantindo a satisfação dos clientes com o produto final.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Todos os direitos reservados — Política de privacidade—Blog