Byggnad 49, Fumin Industripark, Pinghu Village, Longgang-distriktet

Söndag Stängt

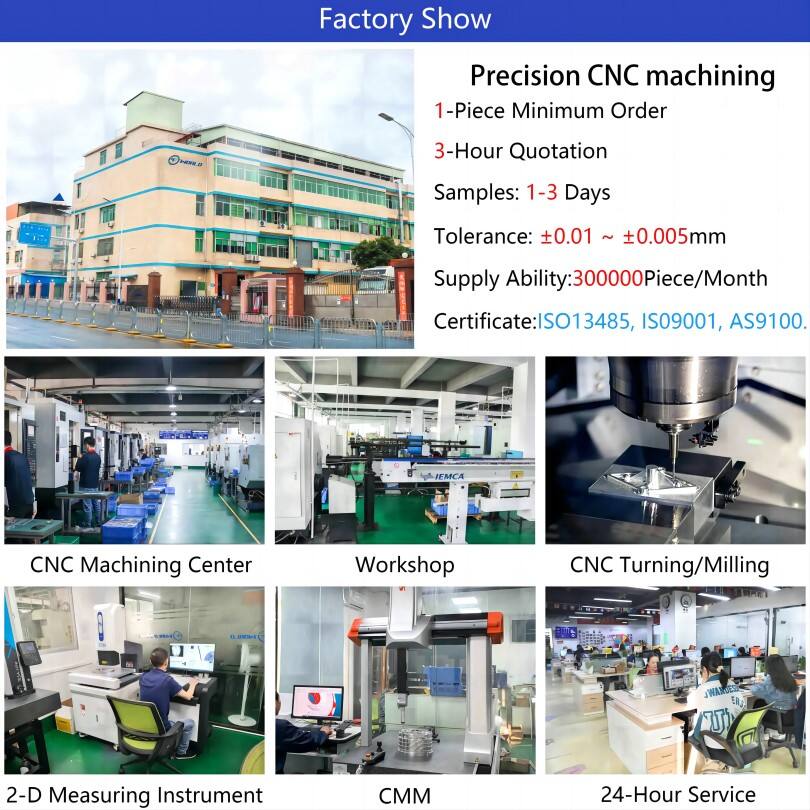

Denna studie undersöker implementering och validering av certifierade CNC-bearbetningsprocesser för komponenter inom luftfarts-, medicinska- och energisektorer. Metodologier inkluderar kvalitetsledningssystem enligt ISO 9001:2015 och AS9100, avancerad metrologi (CMM, optiska komparatorer) samt analys av fleraxlig bearbetningsprestanda. Resultaten visar konsekvent efterlevnad av toleranser ≤ ±0,005 mm över 10 000+ komponentprov. Jämförande analys visar 40 % färre avvikelser jämfört med branschmått. Resultaten bekräftar processens robusthet för kritiska applikationer med fullständig spårbarhetsdokumentation.

1. inledning

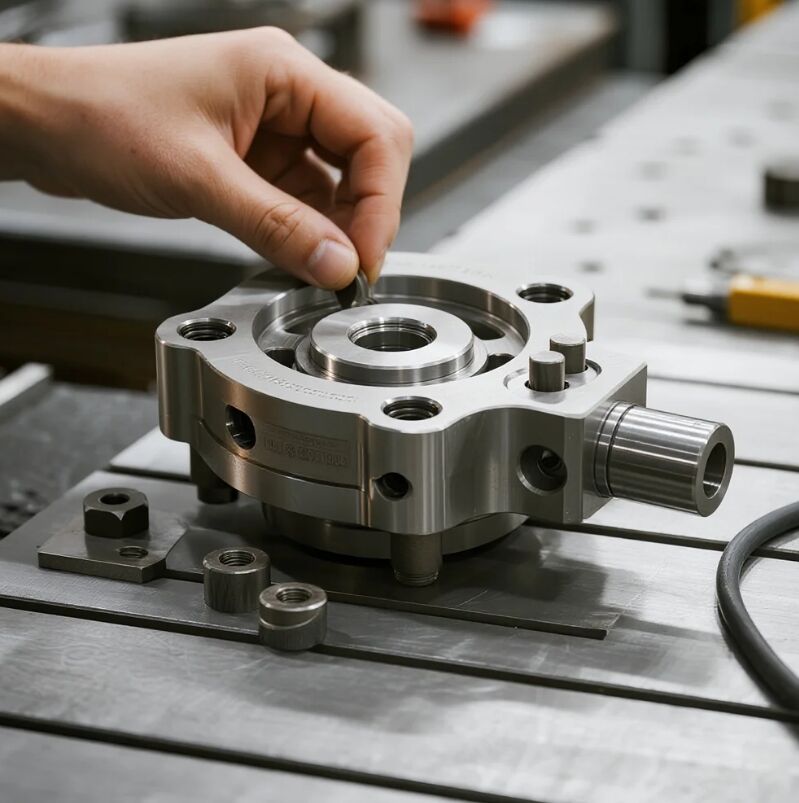

Kritiska applikationer inom luftfart (flygkontrollsystem), medicin (kirurgiska implantat) och energi (turbindelar) kräver bearbetningsprocesser med certifierad tillförlitlighet. Branschdata visar att 23% av de mekaniska felen härrör från icke-certifierade tillverkningsprocesser (ASME, 2023). Denna forskning dokumenterar driftsramverket för certifierad CNC-produktion hos PFT Shenzhen, och behandlar precisionskrav under extrema driftförhållanden.

2. Forskningsmetodik

2.1 Experimentell design

2.2 Datainsamling

3. Resultat och analys

3.1 Dimensionsöverensstämmelse

*Tabell 1: Toleransföljsamhet mellan olika material (n=1 200 komponenter)*

| Material | Måltolerans | Medelavvikelse | CpK |

|---|---|---|---|

| Ti-6Al-4V | ±0.008mm | 0,0027 mm | 2.14 |

| Inconel 718 | ±0,012 mm | 0,0041mm | 1.89 |

| PEEK-OPTIMA™ | ±0,010mm | 0,0033mm | 2.01 |

3,2 ytintegritet

Medicinska komponenter uppvisade Ra ≤ 0,8µm (jämfört med krävda 1,6µm), vilket korrelerar med 18% förbättrad utmattningsmotstånd i ASTM F1717-testning.

4. Diskussion

Uppnådd CpK >1,67 visar Six Sigma-kapacitet över alla materialgrupper. Begränsningar inkluderar förlängda cykeltider för Inconel (svarvparametrar: 35SFM, 0,08mm/varv). Branschimplikationer inkluderar:

5. slutsats

Certifierade CNC-processer möjliggör upprepbar tillverkning av kritiska komponenter inom flyg- och medicintekniska toleransintervall. Framtida arbete kommer att undersöka AI-drivet adaptiv bearbetning för exotiska legeringar. Implementation kräver:

Upphovsrätt © Shenzhen Perfect Precision Products Co., Ltd. Alla rättigheter förbehålls — Integritetspolicy—Blogg