Byggnad 49, Fumin Industripark, Pinghu Village, Longgang-distriktet

Söndag Stängt

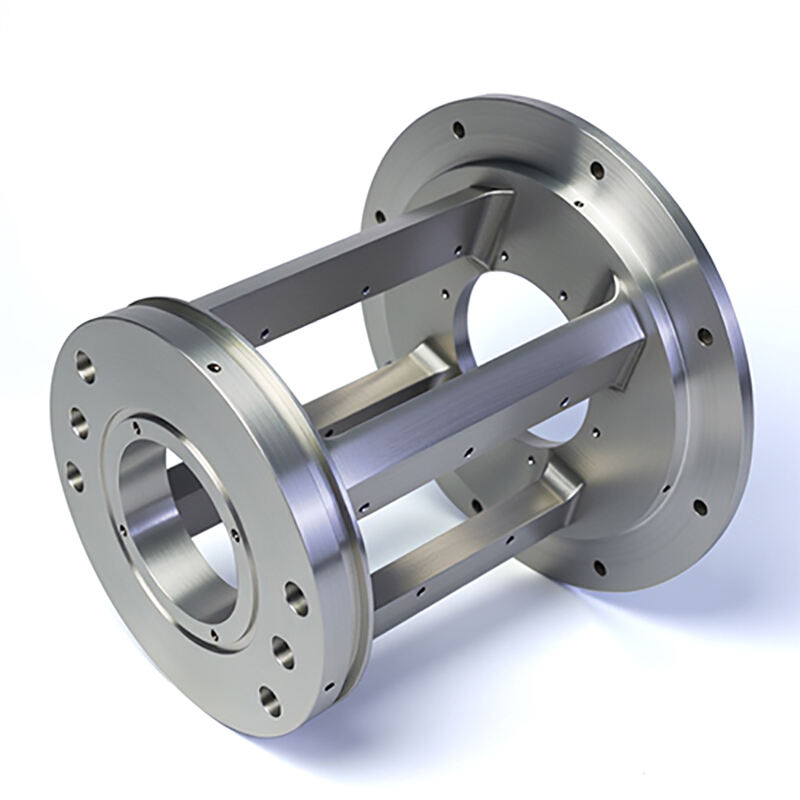

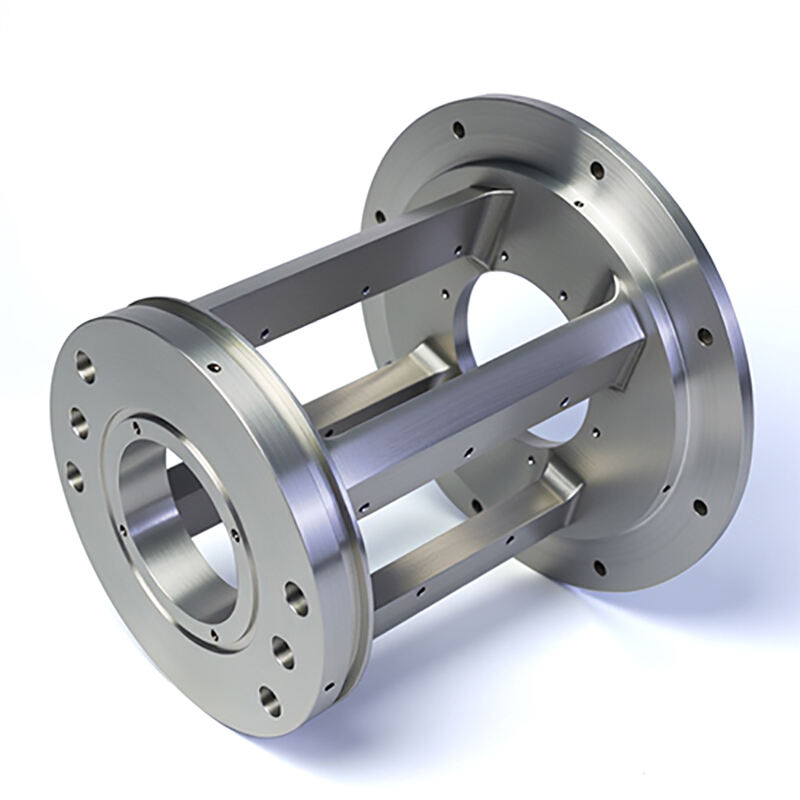

Precisionsbearbetningsdelar

Typ:Skivning, BOBORRNING, Etchning/Kemisk bearbetning, Laserbearbetning, Fräsning, Andra maskinbearbetningstjänster, Vridning, TrådEDM, Snabbprototypering

Modellnummer:OEM

Nyckelord:CNC-maskinbearbetningstjänster

Material: rostfritt stål aluminiumlegering mässing metall plast

Bearbetningsmetod: CNC-fräsning

Leveranstid:7-15 dagar

Kvalitet:Hög kvalitet

Certifiering:ISO9001:2015/ISO13485:2016

MOQ: 1Styck

Undra aldrig hur komplexa metallkomponenter man går från en digital design till ett fysiskt objekt i handen? Det är magin bakom Cnc-mackning . Det är den bakomliggande processen som skapar allt från små medicinska komponenter till stora flygdelar med otrolig precision.

CNC står för Datoriserad numerisk styrning . Med enkel förklaring är det en tillverkningsprocess där datorer styr skärverktyg för att forma metall (eller andra material) med extrem precision.

Tänk dig som en robotiserad skulptör som kan hugga ut metall i i princip vilken form som helst du kan tänka dig – så länge du kan designa det i 3D-programvara.

• Galet exakt: Vi talar om toleranser inom ±0,025 mm eller ännu tätare. Det är tunnare än ett människohår!

• Konsekvens: Den första och den tusende delen kommer att vara identiska.

• Flexibilitet vad gäller material: Fungerar med allt från aluminium och rostfritt stål till titan och exotiska legeringar.

• Komplexitetsmästare: Den kan skapa former som är omöjliga med andra metoder.

Olika projekt behöver olika material. Här är en snabb guide:

• Aluminium

• Rostfritt stål

• Titan

• Mässing

• Koppar

• Medicinsk: Kirurgiska instrument, implantatkomponenter

• Flyg: Motordelar, landningsställkomponenter

• Bilindustri: Prototypklämmor, specialanpassade fästen

• Elektronik: Kylflänsar, höljen, kontaktdon

• Robotik: Leger, drivdon, specialväxlar

Precision är inte bara en marknadsföringsterm – det är en mätbar standard:

• Smala toleranser: Vanligtvis mellan ±0,025 mm till ±0,125 mm

• Ytfinish: Jämna ytor under 0,4 μm Ra

• Upprepbarhet: Varje del matchar den digitala konstruktionen exakt

• Dokumentation: Inspektionsrapporter som verifierar kritiska mått

Oavsett om du behöver en prototyp eller tusentals produktionsdelar, så levererar CNC-bearbetning precision och tillförlitlighet som är svåra att slå

Fråga: Hur snabbt kan jag få ett CNC-prototyp?

Svar: Leveranstiden varierar beroende på delens komplexitet, materialtillgänglighet och ytbehandlingskrav, men i allmänhet:

• Enkla prototyper: 1–3 arbetsdagar

• Komplexa eller flerdelade projekt: 5–10 arbetsdagar

Förspottad service är ofta tillgänglig.

Fråga: Vilka designfiler behöver jag lämna?

Svar: För att komma igång bör du skicka in:

• 3D CAD-filer (helst i STEP-, IGES- eller STL-format)

• 2D-ritningar (PDF eller DWG) om specifika toleranser, gängor eller ytbehandlingar krävs

Fråga: Kan ni hantera tajta toleranser?

Svar: Ja. CNC-fräsning är idealisk för att uppnå tajta toleranser, vanligtvis inom:

• ±0,005" (±0,127 mm) standard

• Striktare toleranser kan erhållas vid begäran (t.ex. ±0,001" eller bättre)

Fråga: Är CNC-prototypframtagning lämplig för funktionsprov?

A: Ja. CNC-prototyper är tillverkade av riktiga ingenjörsgraderade material, vilket gör dem idealiska för funktionsprov, passningskontroller och mekaniska utvärderingar.

Q: Erbjuder ni produktion i små volymer utöver prototyper?

A: Ja. Många CNC-tjänster erbjuder mellanproduktion eller tillverkning i små volymer, idealiskt för kvantiteter från 1 till flera hundra enheter.

Q: Är min design konfidentiell?

A: Ja. Pålitliga tjänster för CNC-prototyper undertecknar alltid sekretessavtal (NDAs) och behandlar dina filer och immateriella rättigheter med full konfidentialitet.

Upphovsrätt © Shenzhen Perfect Precision Products Co., Ltd. Alla rättigheter förbehålls — Integritetspolicy—Blogg