Gusali 49, Fumin Industrial Park, Pinghu Village, Distrito ng Longgang

Sunday Closed

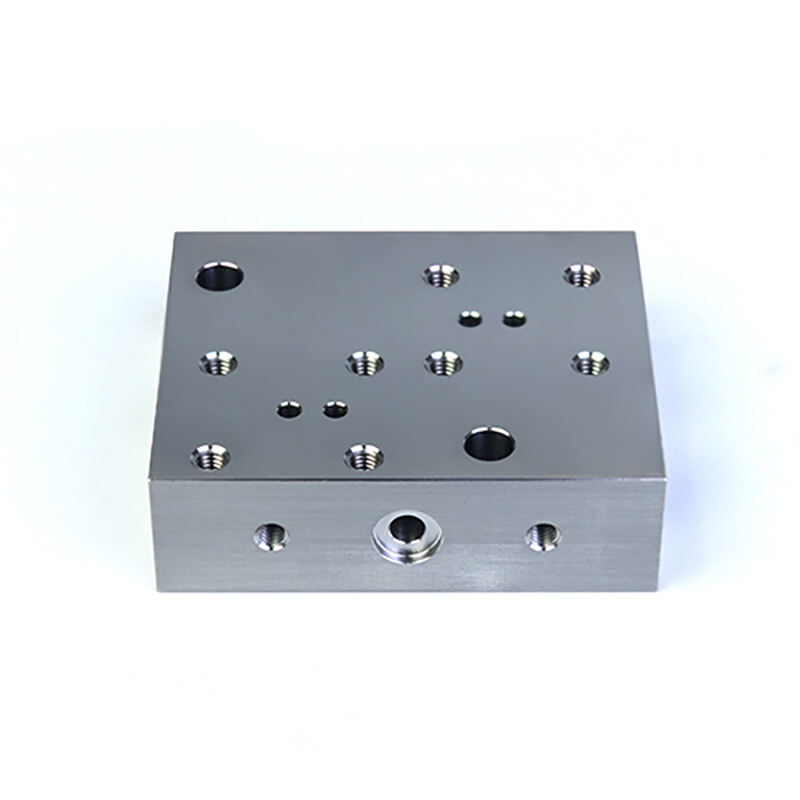

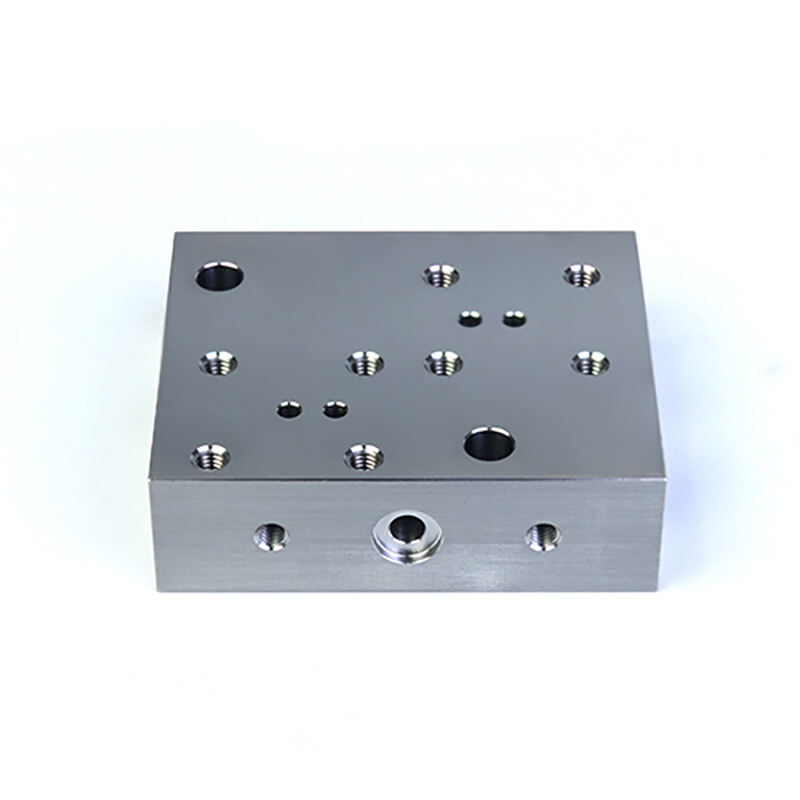

Precision Machining Parts

Uri:Broaching, DRILLING, Pag-eetch, Chemical Machining, Laser Machining, Milling, Iba pang Servisong Paghuhukay, Turning, Wire EDM, Mabilis na Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material: stainless steel aluminum alloy brass metal plastic

Processing method :CNC Turning

Oras ng Pagpapadala:7-15 araw

Kalidad:Mataas na Kalidad

Sertipikasyon:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

Kung ikaw ay nagmamaneho na kahit minsan sa isang tulay, nagtrabaho sa isang mataas na gusali, o gumamit ng mabigat na makinarya nakinabang ka na mula sa mga plakang bakal. Ang mga patag, maraming gamiting sheet ng bakal ay naroroon sa lahat ng lugar—matibay, maaasahan, at madalas nakatago nang simple lamang.

Mga bakal na plato ay makapal, patag na mga sheet ng bakal, na karaniwang may kapal na 3mm hanggang mahigit 200mm. Ginagawa ito sa pamamagitan ng pag-roll o pag-cast ng natunaw na bakal sa malalaking slab, na pagkatapos ay pinuputol sa tamang sukat. Hindi tulad ng mas manipis na sheet metal ginagamit ang mga plakang bakal kung saan kailangan ang tunay na lakas at tibay.

Nagmumula ito sa kanilang kamangha-manghang mga katangian:

• Lakas: Kayang suportahan ang napakabigat na karga nang hindi bumubuwelo o pumuputok.

• Tibay: Lumalaban sa impact, pagsusuot, at matitinding panahon.

• Pagkamaraming gamit: Maaaring putulin, i-weld, butasin, at hugisang para sa walang bilang na aplikasyon.

• Kaligtasan: Nagbibigay ng istrukturang integridad sa mga kritikal na kapaligiran tulad ng konstruksyon at transportasyon.

Hindi lahat ng plating na bakal ay pareho. Narito ang ilan sa pinakakaraniwang uri:

1. Plating na Bakal na Ma-mild

• Gamit: Pangkalahatang konstruksyon, frame, base ng makinarya.

• Mga Benepisyo: Abot-kaya, madaling i-weld at ma-machine.

2. Mataas na Lakas na May Mababang Haluang Metal (HSLA) na Plating

• Gamit: Mga tulay, tore, mabibigat na kagamitan.

• Mga Bentahe: Mas matibay kaysa sa maikli na bakal, mas mahusay na paglaban sa korosyon.

3. Mga Plaka ng Stainless Steel

• Gamit: Paggawa ng pagkain, kagamitan sa medisina, mga tangke ng kemikal.

• Mga Bentahe: Lumalaban sa kalawang at mantsa, madaling linisin.

5. Mga Plakang Nakakaresist sa Pagkasugat (Abrasion-Resistant o AR)

• Gamit: Kagamitan sa mining, mga palid ng bulldozer, makinarya sa quarry.

• Mga Bentahe: Napakahirap na ibabaw na nakakatiis sa mabigat na pagsusuot at pagkasira.

5. Mga Plakang Tool Steel

• Gamit: Mga die, mold, kasangkapan sa pagputol.

• Mga Bentahe: Katigasan at paglaban sa init para sa mga aplikasyong nangangailangan ng tumpak na gawa.

• Konstruksyon: Mga skyscraper, tulay, at mga gusaling pang-industriya.

• Paggawa ng Barko: Mga hull, deck, at mga bahagi ng istraktura.

• Mabigat na Makinarya: Mga excavator, cranes, at kagamitang pang-agrikultura.

• Sektor ng Enerhiya: Mga toreng pang-turbina ng hangin, oil rig, at suporta ng pipeline.

• Depensa: Mga sasakyang militar, panakip na armado, at imprastruktura.

Ang mga hilaw na steel plate ay bihira lang manatiling 'gaya ng orihinal.' Halos lagi silang dinadagdagan o binabago sa pamamagitan ng:

• Pagputol: Gumagamit ng laser, plasma, o waterjet para sa hugis.

• Pagbubukod: Ibinabaluktot sa mga kurba o anggulo gamit ang press brake.

• Pagpuputol: Pinagsama sa ibang bahagi para sa mga istrukturang pagkakahimpil.

• Pagbuho/Pagtutudla: Nadagdagan ng mga butas para sa mga turnilyo at koneksyon.

• Panlabas na Paggamot: Pintura, galvanisasyon, o patong para sa proteksyon laban sa korosyon.

Patuloy ang inobasyon sa:

• Mas matitibay na uri na nagbibigay-daan sa mas magaang pero mas matitibay na disenyo.

• Mas mahusay na patong para sa mas mahabang buhay sa matitinding kapaligiran.

• Automatikong paggawa gamit ang robotics at AI para sa tumpak na pagputol at pagsali.

Maaaring hindi makabagbag-puso ang mga plaka ng bakal, ngunit isa sila sa pinakamahalagang materyales sa inhinyeriya at konstruksyon. Mula sa suporta sa mga tore hanggang sa pagtitiis sa matitinding industriyal na gamit, nagtatanghal sila ng walang kamukha-mukhang pagganap at katiyakan.

Kung gumagawa ka man ng bagong istraktura, nagre-repair ng kagamitan, o gumagawa ng prototype ng produkto, ang pag-unawa sa mga plaka ng bakal ay makatutulong upang gumawa ka ng mas matalino, ligtas, at mas epektibo sa gastos na mga desisyon.

Tanong: Gaano kabilis makakatanggap ang isang prototype ng CNC?

Sagot: Ang mga oras ng paghahatid ay nakadepende sa kumplikadong bahagi, kagampanan ng materyales, at mga kinakailangan sa pagtatapos, ngunit karaniwan:

• Simpleng prototype: 1–3 araw ng negosyo

• Komplikado o maramihang proyekto: 5–10 araw ng negosyo

Maaaring magamit ang expedited serbisyo.

Tanong: Anong mga file ng disenyo ang dapat kong ibigay?

Sagot: Upang magsimula, dapat mong isumite:

• Mga file ng 3D CAD (gusto sa STEP, IGES, o STL format)

• Mga 2D drawing (PDF o DWG) kung kinakailangan ang tiyak na toleransiya, thread, o surface finishes

Tanong: Maari mo bang gawin ang mga siksik na toleransiya?

Sagot: Oo. Ang CNC machining ay mainam para makamit ang siksik na toleransiya, karaniwan sa loob ng:

• ±0.005" (±0.127 mm) standard

• Mas masikip na toleransiya ay available kapag hiniling (hal., ±0.001" o mas mabuti pa)

Tanong: Angkop ba ang CNC prototyping para sa functional testing?

Oo. Ang mga prototype ng CNC ay gawa sa tunay na mga materyales na pang-inhinyero, na nagpapagawa itong perpekto para sa pagsubok ng pag-andar, pag-check ng pagkakasya, at mga pagtatasa ng mekanikal.

Nag-aalok ba kayo ng produksyon sa maliit na dami bukod pa sa mga prototype?

Oo. Maraming mga serbisyo ng CNC ang nagbibigay ng bridge production o produksyon sa maliit na dami, na angkop para sa mga dami mula 1 hanggang ilang daanang yunit.

Pribado ba ang aking disenyo?

Oo. Ang mga kagalang-galang na serbisyo ng prototype ng CNC ay palaging nagpapakita ng Non-Disclosure Agreements (NDAs) at itinuturing ang iyong mga file at intelektwal na ari-arian nang may buong pagkawala ng tiwala.

Karahasan sa Pag-aari © Shenzhen Perfect Precision Products Co., Ltd. Lahat ng Karapatang Rezervado — Patakaran sa Pagkapribado—Blog