Tòa nhà 49, Khu công nghiệp Fumin, thôn Pinghu, quận Longgang

Chủ nhật Nghỉ

Bánh răng chính xác tùy chỉnh là các thành phần quan trọng trong robot, thiết bị y tế, hệ thống phụ ô tô và bộ truyền công nghiệp. Nếu bạn đang tìm kiếm dịch vụ thiết kế và sản xuất bánh răng , hướng dẫn này giải thích các lựa chọn sản xuất thực tế, các yếu tố ảnh hưởng đến chi phí, các mốc kiểm soát chất lượng, và cách lựa chọn nhà cung cấp đáp ứng được độ dung sai, bề mặt hoàn thiện và tính lặp lại.

Tại sao độ chính xác quan trọng: dung sai, tuổi thọ, độ ồn và hiệu suất

Các quy trình điển hình và thời điểm sử dụng (phay lăn răng, xọc răng, mài, cộng thêm)

Vật liệu, xử lý nhiệt và độ hoàn thiện bề mặt cho bánh răng

Một nghiên cứu điển hình/tổng hợp có kết quả đo lường được

Mô hình chi phí + tính toán mẫu để người mua có thể so sánh báo giá

Danh sách từ khóa đuôi dài tập trung vào SEO và câu hỏi thường gặp (sẵn sàng cho đánh dấu Schema)

Bánh răng độ chính xác cao ảnh hưởng đến độ rơ, gợn mô-men xoắn, NVH (độ ồn - rung động - độ giật) và tuổi thọ sử dụng. Ví dụ, việc giảm sai số bước răng từ 0,02 mm xuống 0,005 mm có thể làm giảm rõ rệt độ rung trong các giai đoạn chính xác — đó là lý do kiểm tra (CMM, thử nghiệm lăn bánh răng) là một phần của quy trình, chứ không phải là bước bổ sung.

Các tín hiệu quan trọng từ người mua: mô-đun/DP yêu cầu, số răng, chiều rộng mặt, vật liệu, độ cứng, cấp độ dung sai (ví dụ: AGMA/ISO), độ hoàn thiện bề mặt (Ra), số lượng lô hàng và thời gian giao hàng mong muốn.

| Quy trình | Ứng dụng điển hình | Độ chính xác (điển hình) |

|---|---|---|

| Phay lăn răng (CNC) | Sản xuất số lượng lớn, bánh răng thẳng/xoắn | ±0,01–0,05 mm (phay lăn hàng loạt) |

| Định hình | Bánh răng nhỏ, bánh răng trong | ±0,01–0,05 mm |

| Mài bánh răng | Gia công tinh cuối cùng để đạt độ chính xác cao | ±0,002–0,01 mm |

| Khoan broaching | Then hoa trong/bánh răng trong | dung sai chặt cho then hoa |

| Phay/CNC tiện | Nguyên mẫu / hình học phi tiêu chuẩn | ±0,01–0,05 mm |

| Cộng thêm + hoàn thiện | Hình học phức tạp, sản lượng thấp | phụ thuộc vào gia công sau đó |

| Xử lý nhiệt (thấm carbon/nitride/cảm ứng) | Tăng độ cứng bề mặt và tuổi thọ chống mài mòn | độ cứng 48–62 HRC (phụ thuộc vào quá trình xử lý) |

Khi nào nên chọn mài: sử dụng khi yêu cầu cấp AGMA/ISO có sai số bước răng/dẫn hướng thấp (cho servo hoặc hàng không vũ trụ).

Khi nào nên chọn phay lăn răng: hiệu quả cho các lô sản xuất mà việc gia công sau mài là tùy chọn.

Thép hợp kim: 4140, 8620 (có thể thấm carbon) — phổ biến cho bánh răng chịu tải cao.

Thép không gỉ: 17-4 PH, 304/316 (độ chống mài mòn thấp hơn trừ khi được xử lý bề mặt).

Đồng thau/đồng thanh: tiếp xúc trượt (bộ truyền trục vít).

Nhựa kỹ thuật: PA, POM, nylon cho ứng dụng tải thấp, ít ồn.

Các phương pháp xử lý điển hình: thấm carbon + tôi & ram (độ cứng bề mặt 55–62 HRC), thấm nitơ (tốt cho chịu mỏi, biến dạng thấp hơn), tôi cảm ứng (tôi cứng cục bộ).

Mục tiêu độ nhám bề mặt: bánh răng hộp số thường yêu cầu Ra 0,4–1,6 µm sau khi mài/bóng.

Nghiên cứu điển hình dạng hợp phần (xây dựng từ nhiều dự án sản xuất):

Dự án: 500 đơn vị — bộ bánh răng trụ xoắn và bánh răng thẳng cho bộ truyền công nghiệp. Vật liệu: 8620, thấm carbon đến độ sâu lớp 0,8 mm, mài tinh đến cấp tương đương AGMA Q10.

Kết quả đo được: sai số bước trung bình giảm từ 0,018 mm (phay lăn) xuống còn 0,004 mm sau gia công tinh; độ đảo <0,005 mm; NVH giảm khoảng 30% (so sánh chủ quan trên bàn thử). Thời gian thực hiện: 6 tuần kể từ bản vẽ được phê duyệt. Tỷ lệ phế phẩm: <1% sau khi tối ưu hóa quy trình.

Bài học rút ra: chế tạo mẫu sớm + kiểm tra một mẫu đơn giúp giảm số lần lặp lại. Việc áp dụng bước khử ứng suất trước khi nhiệt luyện đã giảm thời gian mài sau nhiệt luyện khoảng 20% (tiết kiệm thời gian, ít phải sửa chữa hơn).

Các yếu tố chính ảnh hưởng đến chi phí:

Vật liệu và khối lượng vật liệu

Thời gian chu kỳ cắt và hoàn thiện (phay lăn răng so với mài)

Loại nhiệt luyện và kiểm soát biến dạng (đồ gá, môi trường tôi)

Kiểm tra và chứng nhận (báo cáo CMM, độ đảo, dạng răng)

Kích thước lô hàng và phân bổ chi phí thiết lập

Tính toán mẫu (chỉ mang tính minh họa):

Giả định: 100 chiếc, bánh răng trụ thẳng, phôi 4140, module 1.0, chiều rộng vành răng 12 mm.

Vật liệu thô + phôi: 2,50 USD/chiếc

Phay răng và vê mép: USD 6,00/cái

Nhiệt luyện và mài tinh: USD 8,00/cái

Kiểm tra và đóng gói: USD 1,50/cái

Chi phí chung & lợi nhuận + khấu hao dụng cụ: USD 6,00/cái

Giá đơn vị dự kiến: USD 24,00/cái (ví dụ để so sánh báo giá — yêu cầu các nhà cung cấp cung cấp bảng phân tích chi phí tương tự)

Luôn yêu cầu: chứng chỉ vật liệu (EN/ASTM), báo cáo nhiệt luyện, và báo cáo kiểm tra mẫu đầu tiên.

Kiểm tra mẫu đầu tiên (FAI) kèm báo cáo CMM

Báo cáo sai lệch biên dạng răng/profle/bước răng (kiểm tra ăn khớp bánh răng hoặc CMM)

Báo cáo độ cứng (báo cáo chiều sâu thấm case)

Chứng chỉ vật liệu (báo cáo kiểm tra tại nhà máy)

Mã lô truy xuất được và hướng dẫn đóng gói

7 Swords Precision: Đối Tác Uy Tín Của Bạn Trong Gia Công CNC Theo Yêu Cầu

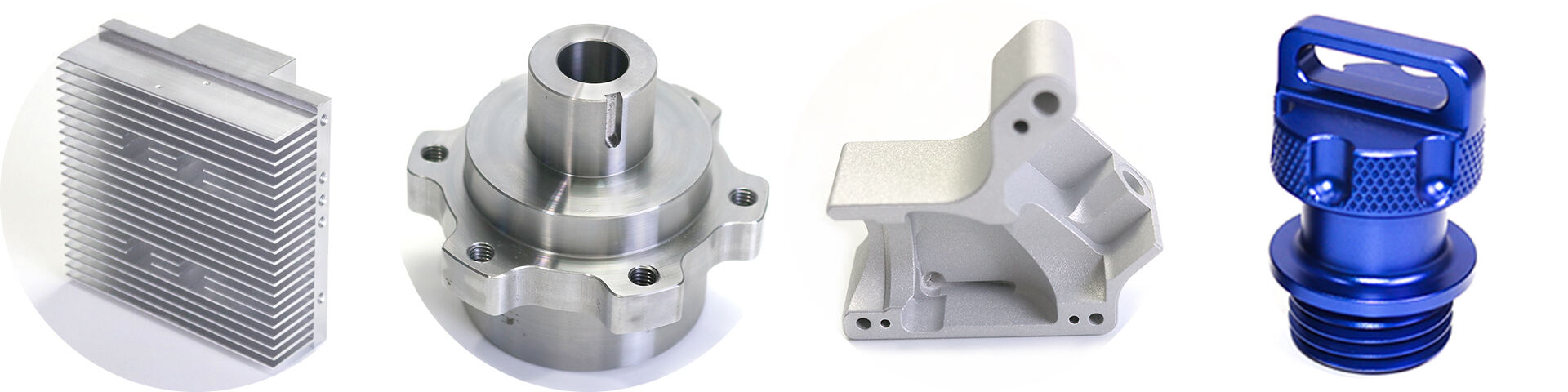

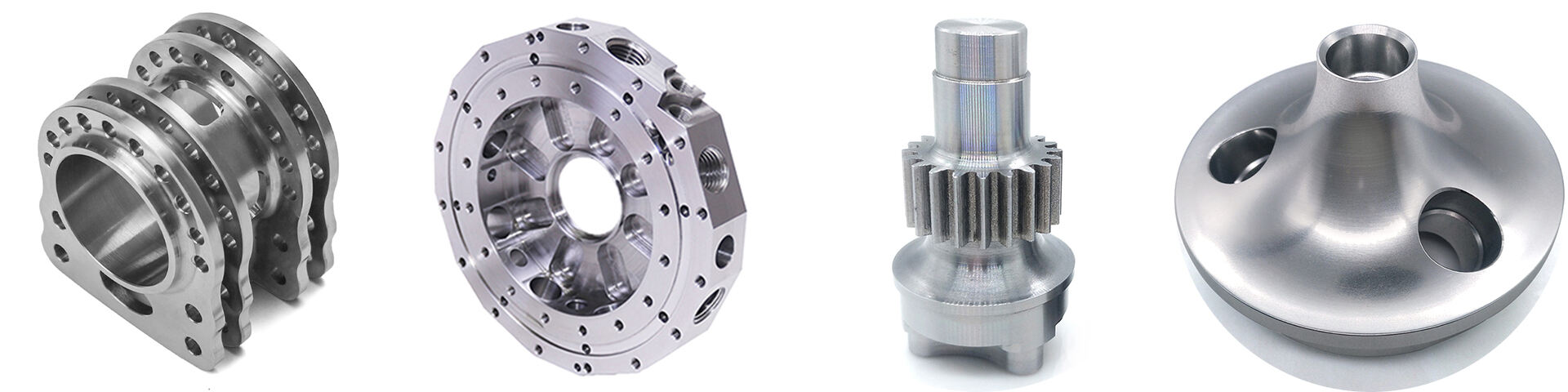

Là nhà cung cấp hàng đầu các bộ phận và linh kiện gia công CNC theo yêu cầu, 7 Swords Precision chuyên về tiện và phay mẫu mã bằng vật liệu kim loại chất lượng cao. Chúng tôi cung cấp các sản phẩm được chế tạo chính xác, phù hợp với các yêu cầu đặc thù của nhiều ngành công nghiệp khác nhau. Cam kết về chất lượng đã giúp chúng tôi trở thành một trong những nhà cung cấp hàng đầu trong lĩnh vực sản xuất CNC trên thị trường.

Chúng tôi tự hào sở hữu nhiều chứng chỉ sản xuất cho dịch vụ gia công CNC, điều này thể hiện cam kết của chúng tôi với chất lượng và sự hài lòng của khách hàng. Đội ngũ của chúng tôi tuân thủ các quy trình kiểm soát chất lượng nghiêm ngặt để đảm bảo mọi bộ phận sản xuất ra đều đáp ứng các tiêu chuẩn cao nhất về chất lượng và độ chính xác

Xử lý |

Phay CNC, Tiện CNC, Cắt Laser, Uốn, Quay, Cắt dây, Đột dập, Machining bằng phóng điện (EDM), Ép nhựa |

|||||||

Vật liệu |

Nhôm: series 2000, series 6000, 7075, 5052, v.v. |

|||||||

Thép không gỉ: SUS303, SUS304, SS316, SS316L, 17-4PH, v.v. |

||||||||

Thép: 1214L/1215/1045/4140/SCM440/40CrMo, v.v. |

||||||||

Đồng: 260, c360, h59, h60, h62, h63, h65, h68, h70, đồng, đồng |

||||||||

Titanium: lớp f1-f5 |

||||||||

Nhựa: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK v.v. |

||||||||

Xử lý bề mặt |

Oxi hóa, Phun bi, In lụa, Mạ PVD, Mạ kẽm/niken/crom/titan, Chải, Sơn phủ, Sơn tĩnh điện, Thụ động hóa, Điện di, Đánh bóng điện, Gia công nhám, Khắc laser/khắc hóa học/khắc sâu v.v. |

|||||||

Dung sai |

±0.002 ~ ±0.005 mm |

|||||||

Độ nhám bề mặt |

Min Ra 0.1~3.2

|

|||||||

Bản quyền © Công ty TNHH Sản phẩm Chế tạo Chính xác Perfect Shenzhen. Tất cả các quyền được bảo lưu — Chính sách bảo mật—Blog