Tòa nhà 49, Khu công nghiệp Fumin, thôn Pinghu, quận Longgang

Chủ nhật Nghỉ

Nếu bạn đang tìm kiếm việc nâng cấp xe hơi của mình với các bộ phận tùy chỉnh tốt nhất trên thị trường, đừng tìm đâu xa nữa hãy đến với Swords Precision. Các sản phẩm kim loại của chúng tôi được chế tạo từ những hợp kim chất lượng cao nhất, đảm bảo độ bền và hiệu suất trong nhiều năm tới. Dù bạn cần dịch vụ phay, gia công cơ khí hay thiết kế, chúng tôi đều đáp ứng bạn với các linh kiện bằng đồng thau và phụ kiện CNC.

Tại Swords Precision, chúng tôi tự hào là một cửa hàng duy nhất cho tất cả các nhu cầu phụ tùng xe hơi tùy chỉnh của bạn. Nhóm kỹ thuật viên có kỹ năng của chúng tôi sử dụng thiết bị hiện đại để tạo ra các bộ phận kỹ thuật chính xác sẽ đưa xe của bạn lên cấp độ tiếp theo. Từ những nâng cấp đơn giản đến những thay đổi phức tạp, chúng tôi có chuyên môn để đưa tầm nhìn của bạn vào cuộc sống.

Một trong những dịch vụ bán chạy nhất của chúng tôi là khả năng phay, cho phép chúng tôi tạo ra các thiết kế và hình dạng phức tạp với độ chính xác vượt trội. Dù bạn cần một tấm tản nhiệt (grille) tùy chỉnh, hệ thống xả khí hay các bộ phận treo (suspension), dịch vụ phay của chúng tôi đều có thể đáp ứng. Dịch vụ gia công cơ khí của chúng tôi cũng không kém phần ấn tượng, đảm bảo mọi bộ phận chúng tôi sản xuất đều đạt tiêu chuẩn cao nhất về chất lượng và hiệu suất.

Ngoài các dịch vụ phay và gia công của chúng tôi, chúng tôi còn cung cấp hỗ trợ thiết kế để giúp bạn tạo ra các bộ phận ô tô tùy chỉnh hoàn hảo cho chiếc xe của mình. Đội ngũ giàu kinh nghiệm của chúng tôi có thể làm việc cùng bạn để phát triển một thiết kế độc đáo phản ánh phong cách và sở thích cá nhân của bạn. Dù bạn thích phong cách hiện đại, gọn gàng hay vẻ đẹp cổ điển hơn, chúng tôi đều có chuyên môn để biến tầm nhìn của bạn thành hiện thực.

Về vật liệu, chúng tôi chuyên về các bộ phận bằng đồng thau, mang lại độ bền và khả năng chống ăn mòn vượt trội. Các bộ phận bằng đồng thau của chúng tôi được chế tạo chính xác để đảm bảo hiệu suất và độ bền tối đa, khiến chúng trở thành lựa chọn lý tưởng cho các bộ phận ô tô tùy chỉnh. Ngoài ra, các phụ kiện CNC của chúng tôi được thiết kế nhằm nâng cao tính năng và hiệu suất của chiếc xe bạn, giúp cá nhân hóa phương tiện đúng theo thông số kỹ thuật mong muốn của bạn.

Swords Precision là địa chỉ tin cậy cung cấp các bộ phận ô tô tùy chỉnh tốt nhất trên thị trường. Với các hợp kim chất lượng cao, dịch vụ phay và gia công, chuyên môn thiết kế, các bộ phận bằng đồng thau, và phụ kiện CNC của chúng tôi, bạn sẽ có mọi thứ cần thiết để nâng cấp phương tiện của mình lên một tầm cao mới. Hãy tin tưởng Swords Precision mang đến sản phẩm và dịch vụ xuất sắc cho mọi nhu cầu về bộ phận ô tô tùy chỉnh của bạn

Chúng tôi tự hào sở hữu nhiều chứng chỉ sản xuất cho dịch vụ gia công CNC, điều này thể hiện cam kết của chúng tôi với chất lượng và sự hài lòng của khách hàng. Đội ngũ của chúng tôi tuân thủ các quy trình kiểm soát chất lượng nghiêm ngặt để đảm bảo mọi bộ phận sản xuất ra đều đáp ứng các tiêu chuẩn cao nhất về chất lượng và độ chính xác

Xử lý |

Tiện CNC, Phay CNC, Cắt laser, Uốn, Xoắn, Cắt dây, Đột dập, Gia công xung điện (EDM), Ép phun, In 3D, Mẫu nhanh, Khuôn mẫu v.v... |

|||||||

Vật liệu |

Nhôm: series 2000, series 6000, 7075, 5052, v.v. |

|||||||

Thép không gỉ: SUS303, SUS304, SS316, SS316L, 17-4PH, v.v. |

||||||||

Thép: 1214L/1215/1045/4140/SCM440/40CrMo, v.v. |

||||||||

Đồng: 260, c360, h59, h60, h62, h63, h65, h68, h70, đồng, đồng |

||||||||

Titanium: lớp f1-f5 |

||||||||

Nhựa: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK v.v. |

||||||||

Xử lý bề mặt |

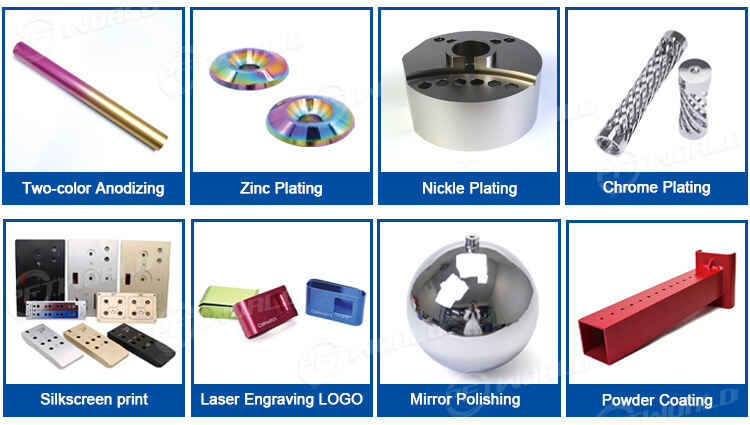

Oxi hóa, Phun bi, In lụa, Mạ PVD, Mạ kẽm/niken/crom/titan, Chải, Sơn phủ, Sơn tĩnh điện, Thụ động hóa, Điện di, Đánh bóng điện, Gia công nhám, Khắc laser/khắc hóa học/khắc sâu v.v. |

|||||||

Dung sai |

+/-0.01 ~ 0.005 mm |

|||||||

Độ nhám bề mặt |

Min Ra 0.1~3.2

|

|||||||

Chứng nhận |

||||||||

1. Bạn là nhà sản xuất hay công ty thương mại?

Chúng tôi là một nhà máy đặt tại Thâm Quyến, Trung Quốc, có 20 năm kinh nghiệm phong phú, diện tích hơn 6000 mét vuông. Cơ sở đầy đủ, bao gồm thiết bị kiểm tra chất lượng 3D, hệ thống ERP và 40 máy móc. Nếu cần thiết, chúng tôi có thể cung cấp cho bạn các báo cáo như chứng chỉ vật liệu, kiểm tra chất lượng mẫu và các báo cáo khác

2. Làm thế nào để nhận được báo giá3. Tôi có thể nhận báo giá mà không có bản vẽ được không

Đội ngũ kỹ thuật của bạn có thể vẽ theo ý tưởng của tôi không? Tất nhiên rồi, chúng tôi cũng rất sẵn lòng nhận các mẫu, hình ảnh hoặc bản phác thảo kích thước chi tiết của bạn để đưa ra báo giá chính xác

4. Bạn có thể cung cấp mẫu trước khi sản xuất hàng loạt không

Tất nhiên, phí mẫu là cần thiết. Nếu có thể, phí này sẽ được hoàn lại trong quá trình sản xuất hàng loạt

5. Thời gian giao hàng là bao lâu

Thông thường, thời gian làm mẫu là 1-2 tuần và sản xuất lô hàng mất khoảng 3-4 tuần

6. Bạn kiểm soát chất lượng như thế nào

(1) Kiểm tra vật liệu - Kiểm tra bề mặt vật liệu và kích thước gần đúng.

(2) Kiểm tra lần đầu sản xuất - đảm bảo các kích thước quan trọng trong quá trình sản xuất hàng loạt.

(3) Kiểm tra lấy mẫu - kiểm tra chất lượng trước khi giao hàng vào kho.

(4) Kiểm tra trước khi xuất hàng - kiểm tra 100% bởi nhân viên QC trước khi vận chuyển.

7. Đội ngũ dịch vụ sau bán hàng

Nếu bạn gặp bất kỳ vấn đề nào sau khi nhận sản phẩm, bạn có thể phản hồi thông qua cuộc gọi thoại, hội nghị video, email, v.v. trong vòng một tháng. Đội ngũ của chúng tôi sẽ cung cấp giải pháp cho bạn trong vòng một tuần

Bản quyền © Công ty TNHH Sản phẩm Chế tạo Chính xác Perfect Shenzhen. Tất cả các quyền được bảo lưu — Chính sách bảo mật—Blog