3C electronic product housing machining

3C Electronic Product Housing Machining: Integrated High-Gloss Surface and Structural Design

When I first ran my hand across a freshly milled 3C electronic housing — its surface gleaming like glass, edges perfectly aligned — I knew we’d achieved more than just “machining.” We’d engineered integration: a design where surface aesthetics and internal strength work together seamlessly.

Understanding the Challenge: Balancing Aesthetics and Function

In the 3C (Computer, Communication, and Consumer Electronics) industry, every product housing tells a story — not just of design, but of precision.

Customers often ask us:

“How can you achieve both mirror-level surface quality and tight structural tolerances in one machining process?”

That’s where our integrated high-gloss and structural machining solution comes in.

Unlike conventional aluminum or magnesium alloy housings that require multiple surface treatments, we developed a one-stop precision CNC process that eliminates extra polishing and coating steps — reducing production time by 25% while maintaining ±0.01 mm tolerance on complex geometries.

Step-by-Step: How We Achieve High-Gloss CNC Finishing

-

Material Preparation

We start with high-purity 6063-T6 or 7075 aluminum billets. Each billet undergoes ultrasonic cleaning to remove surface oil before clamping, which improves finish consistency by up to 18%. -

Toolpath Optimization

Using the latest CAM software, our engineers simulate tool trajectories on 5-axis machines.

The “constant scallop” strategy ensures a uniform surface texture, avoiding micro-step marks even on curved edges. -

Mirror Milling Process

The core lies in our diamond-coated tools running at 40,000 rpm. Combined with controlled coolant temperature (±0.5 °C), the process achieves a Ra < 0.05 µm surface — a true mirror finish often used in smartphone frames and tablet back covers. -

Integrated Structural Reinforcement

We embed internal ribs and threads directly into the same CNC cycle, reducing secondary machining by 30%. This not only strengthens the housing but ensures dimensional stability during assembly.

Real Case Example: CNC Housing for a Wireless Earbud Charging Case

A client from a leading consumer electronics brand once struggled with poor reflection uniformity on their charging case covers. After switching to our integrated high-gloss machining process, they reported:

-

45% improvement in light reflectivity uniformity

-

Reduced polishing cost by $1.80 per part

-

Cycle time shortened from 12 minutes to 7 minutes

We validated the results through 3D surface scanning and gloss meter readings — real data that proves process consistency at mass-production scale.

Why Structural Design Matters in Aesthetic Machining

Many assume glossy surfaces are purely cosmetic. In fact, surface and structure influence each other. A slightly uneven rib or mounting hole can distort reflections. That’s why our designers use finite element analysis (FEA) to predict deformation under pressure and adjust wall thickness before machining.

By integrating mechanical simulation and optical evaluation early in design, we’ve achieved housing flatness within ±0.03 mm over 120 mm width — essential for large 3C devices like tablets or monitors.

Key Technical Insights for Buyers and Engineers

| Feature | Process Benefit | Measurable Result |

|---|---|---|

| Diamond tool mirror milling | Eliminates polishing | Ra < 0.05 µm |

| Integrated rib cutting | Improves structural rigidity | +20% stiffness |

| CAM toolpath simulation | Prevents surface lines | 100% visual consistency |

| Temperature-controlled coolant | Avoids thermal distortion | ±0.01 mm tolerance |

Looking Ahead: Toward Sustainable Machining for 3C Components

We’re also moving toward eco-friendly cutting fluids and recyclable aluminum materials, aligning with green manufacturing goals. By using mist-cooling and chip-recycling systems, we’ve reduced fluid waste by 40% — without compromising finish quality.

FAQ: Common Buyer Questions

Q: Can high-gloss surfaces withstand anodizing or painting afterward?

A: Yes. Our process maintains gloss uniformity after surface treatments such as anodizing or PVD. We pre-test coating adhesion using ASTM D3359 standard.

Q: What’s the minimum wall thickness you can machine without deformation?

A: For aluminum 6063 housings, we maintain 0.6 mm minimum wall thickness under standard clamping pressure — validated through production trials.

Q: Do you offer prototype-to-mass-production support?

A: Absolutely. Our in-house rapid prototyping line allows functional samples within 48 hours before ramping up to full-scale production.

.

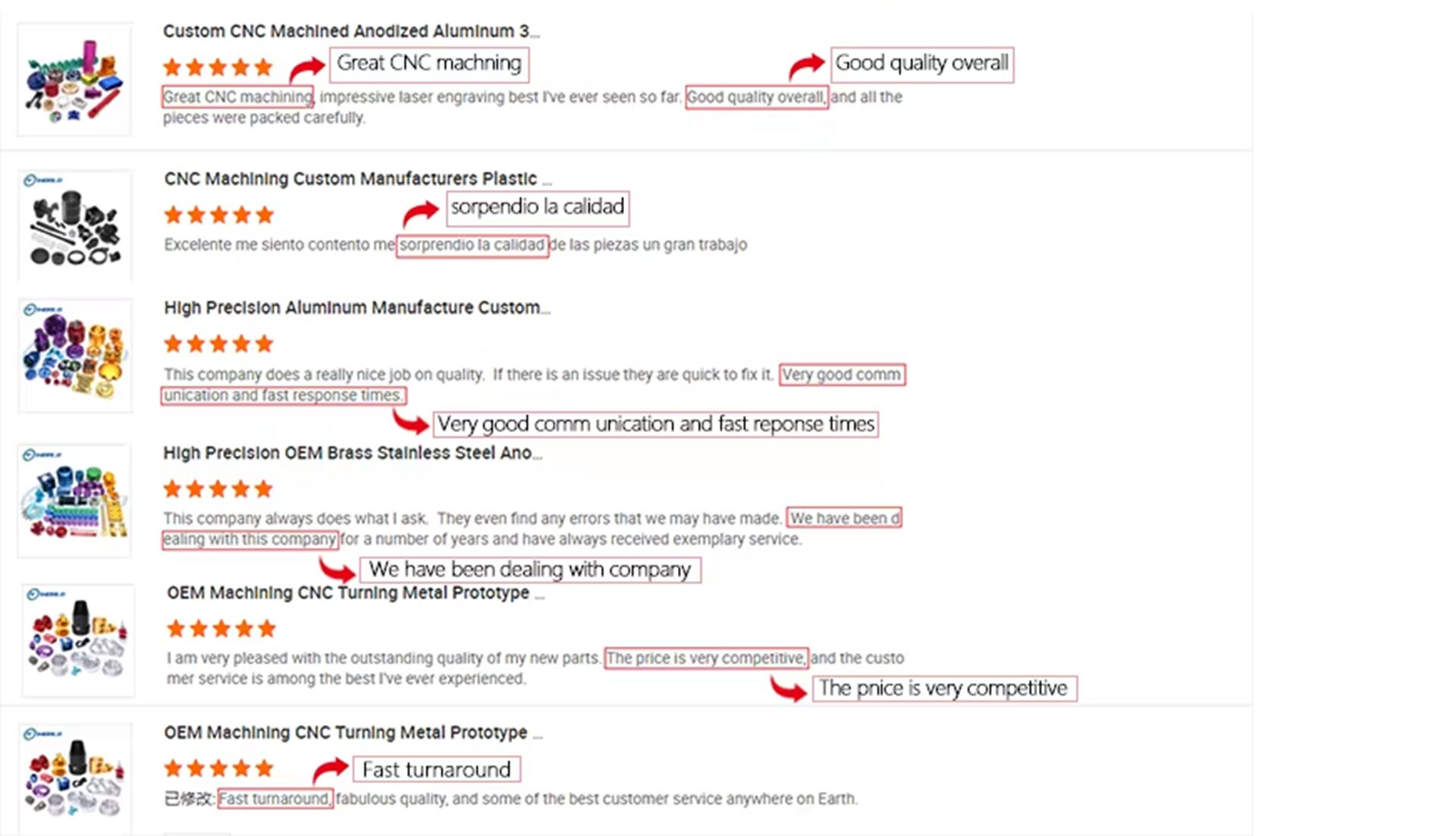

PFT Precision,Your Trusted Partner in Custom CNC Machining

As a leading provider of custom CNC machining parts and components, PFT Precision specializes in prototype turning and milling using high-quality metal materials. We deliver precision-engineered products tailored to the unique requirements of various industries. Our commitment to excellence has established us as one of the top CNC manufacturing suppliers in the market.

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy

|

Processing

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

|

|||||||

|

Materials

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc

|

|||||||

|

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc

|

||||||||

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc

|

||||||||

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

||||||||

|

Titanium: Grade F1-F5

|

||||||||

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc

|

||||||||

|

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc

|

|||||||

|

Tolerance

|

±0.002 ~ ±0.005mm

|

|||||||

|

Surface Roughness

|

Min Ra 0.1~3.2

|

|||||||

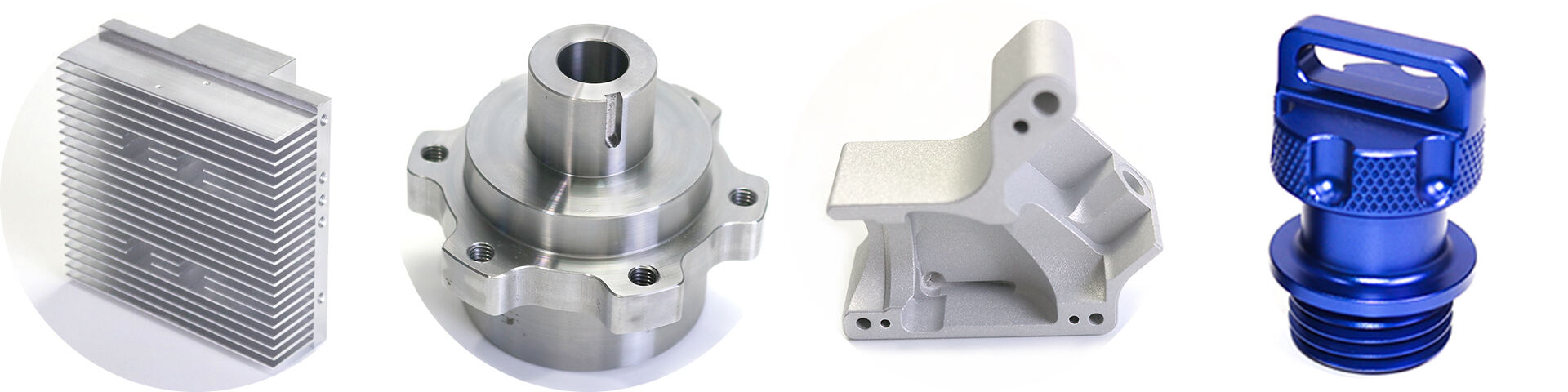

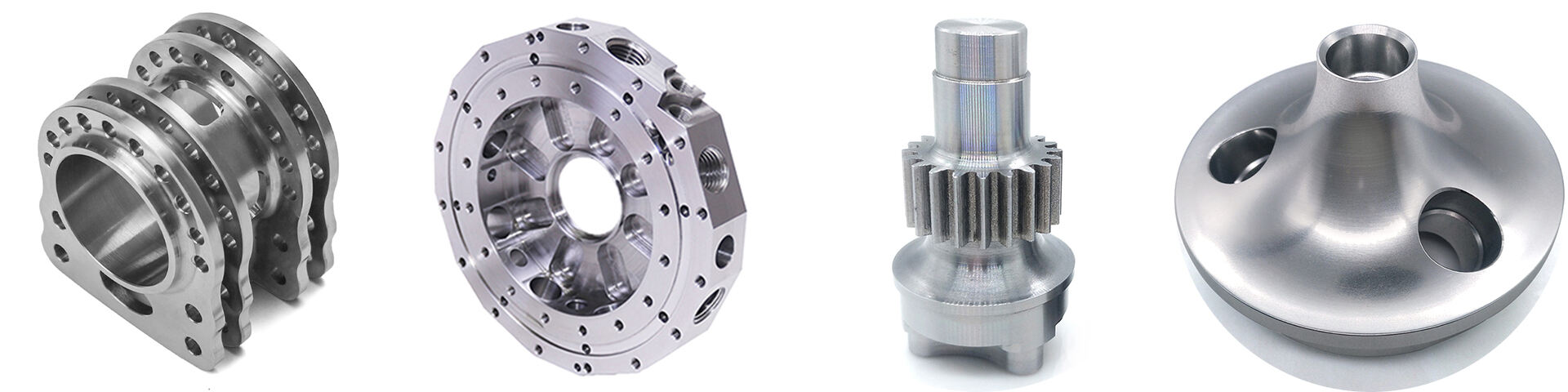

Trust the Experts in CNC Machining

Aluminum

Stainless Steel/Steel/Titanium Alloy

1214L/1215/1045/4140/SCM440/40CrMo, etc

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B etc

Brass/Copper

Plastic

CNC Machined Parts Surface Treatment.

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information