Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

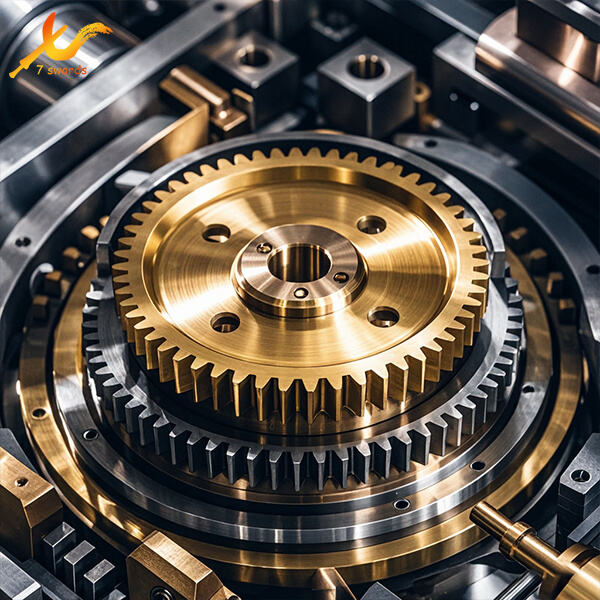

One of them is Swords Precison, that focuses on CNC parts design Design. These parts are made based on the individual requirements of industries and are used in numerous factories through the use of special machinery which has been developed over their years. In other words, no matter what type it is or how big and small the part is Swords Precision can handle anything.

When it comes to producing perfect pieces through the use of CNC design, there is only one key element that must be achieved. Manufactured to customer specification, each part is custom-fit for specific machine or assembly operation. Birth control is critical, because as we all know, Baby Manufacturing Errors add up into a Big Problem down the road.

This is the reason why Swords Precision knows that anymorea Aluminum CNC parts production, you have to be careful. To get the craft right and to ensure accuracy is of paramount importance, and so does the bonding with your client, understanding the needs of your customer as a partner from beginning to end. This partnership ensures that the results are a direct reflection of what the customer thinks about their ideas.

Smart design practices are a gargantuan portion of speeding up CNC production and this is done by optimizing Smart design practice. It does not do this, in true Enterprising style they adhere to best practice to ensure every component is turned around quickly and to exacting standards. This ensures that they offer customer satisfaction and also work under-pressure deadlines.

The team of Swords Precision CNC parts production knows the importance of a quick turn-around for their clients. Smart design principals now allow them to produce better parts with speed never before possible. Additionally, this plays into their business as well but also ensures they fulfill their customers demand to quickly get products to market.

But at the scale of a team it is just as important to have experts on performance, and experts on cnc parts design. It wins by being able to pay guys who are better at designing parts guys like these but also have been doing it longer, and this is still solid quality. Pair that with their experience in knotty know-how, and the Aerospace CNC parts they make aren't just going to be passable they're as good as you can pretty much, get.

A reputation for advanced 5-Axis machined Automotive CNC parts design for performance enhancement, manufactures parts that tend to meet and surpass the expectations of their clients. Due to this, the mall will possess trust over its machinery still functioning properly and good so that it improves on general efficiency.

They have a wealth of CNC parts design and knowledge to address all your concerns. Their extensive knowledge and expertise will address your concerns. Custom precision parts tolerances: +/- 1 mm, Special Space: +/0.005 mm

OEM and ODM services are available The minimum quantity for orders is 1 piece Quotes are given within CNC parts design Production of samples takes 1 to 3 working days The delivery time for bulk orders is 7 to 14 working days Our monthly production surpasses 300 000

We offer a wide range of production CNC parts design, including 3-axis and 4-axis up to 6-axis. We offer a range of processing capabilities that include turning, milling, and drilling, grinding and EDM, 3D Printing. We work with many different materials like copper, brass and aluminum steel, stainless, plastics and composites.

We have ISO9001 certificate, ISO14001, ISO45001, medical ISO13485, aviation CNC parts design, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog