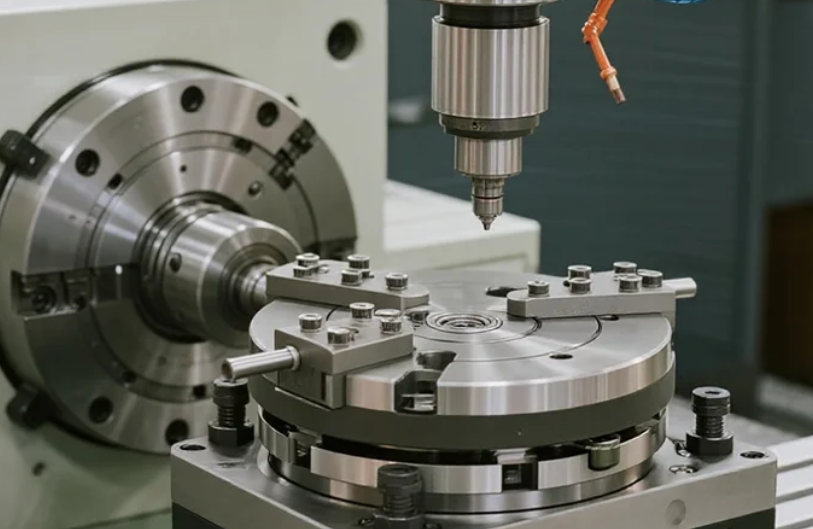

How to Choose a Rotary Table: True 4-Axis vs. 3+2 Positioning

The Costly Consequences of Choosing Wrong

The rhythmic thrum of the spindle, the sharp scent of cutting fluid, the high-pitched screech as the end mill bites into aerospace aluminum – suddenly, a jarring clunk echoes through the shop floor.

Your brand-new rotary table just shuddered violently mid-contour, leaving a nasty gouge on a $5,000 titanium billet. Sound familiar?

Choosing the wrong rotary table isn’t just inconvenient—it’s a direct hit to your bottom line and production schedule.

I’ve been there, sweating over scrapped parts and angry production managers. Let’s cut through the confusion between True 4-Axis and 3+2 positioning—your wallet will thank you.

1. Core Difference: Continuous Motion vs. Indexed Angles

True 4-Axis (Continuous Motion)

-

Allows simultaneous interpolation (all four axes—X, Y, Z, and rotary—move together in perfect coordination).

-

Essential for complex, sculpted surfaces (e.g., impeller blades, turbine components).

-

Requires tight synchronization between CNC controller and rotary drive system.

3+2 Positioning (Indexed Angles)

-

Uses rotary axes only to tilt and lock the workpiece in fixed positions.

-

Machining then proceeds in 3-axis mode (X, Y, Z).

-

Ideal for angled drilling, multi-face milling (e.g., valve bodies, gear housings).

Question: *Does your shop need full 4-axis motion daily, or can you work with strategic repositioning?

2. The Hidden Demands of True 4-Axis

Don’t underestimate the engineering required for reliable simultaneous motion. Key specs are non-negotiable:

-

Extremely low backlash (<10 arc-seconds for precision work).

-

High stiffness & rigidity to resist cutting forces without deflection.

-

Direct-drive motor (or ultra-precise worm gear) for smooth motion.

-

Single-digit arc-second accuracy & repeatability (critical for medical/aerospace).

Warning: *Can your CNC controller handle complex 4-axis toolpaths without lagging?*

3. Why 3+2 Positioning Might Be the Smarter Choice

Most parts don’t require full 4-axis motion. Benefits of 3+2:

-

Simpler programming (3-axis toolpaths are well-understood).

-

Lower machine demands (higher backlash tolerance, less rigidity needed).

-

Cost-effective (worm gears or hydraulic indexers often suffice).

Example: Machining a valve body? Position, lock, machine—repeat.

4. A Painful Lesson Learned

We once bought a "4-axis capable" rotary table at a "bargain" price.

Result:

-

Excessive backlash caused violent shuddering mid-cut.

-

Scrapped part + $800 broken cutter.

-

Hours of downtime troubleshooting.

Lesson: "Capable" doesn’t mean "suitable." Match specs to real cutting conditions.

5. How to Choose Wisely: Ask These Questions

-

What % of jobs truly need continuous 4-axis motion?

-

What are your max cutting forces (radial & axial)?

-

What surface finish & accuracy are mandatory?

-

Does your CNC support RTCP (Rotary Tool Center Point)?

-

Demand test reports (backlash, stiffness, repeatability).

Final Tip: Get a performance warranty based on your machining needs.

Conclusion

The right rotary table ensures your shop hums with precision—not the costly sound of failure.

Choose based on real needs, not just specs. Your bottom line depends on it.