3C էլեկտրոնային արտադրանքի կազմի մշակում

3C էլեկտրոնային արտադրանքի կազմի մշակում. Ինտեգրված բարձր փայլուն մակերես և կառուցվածքային դիզայն

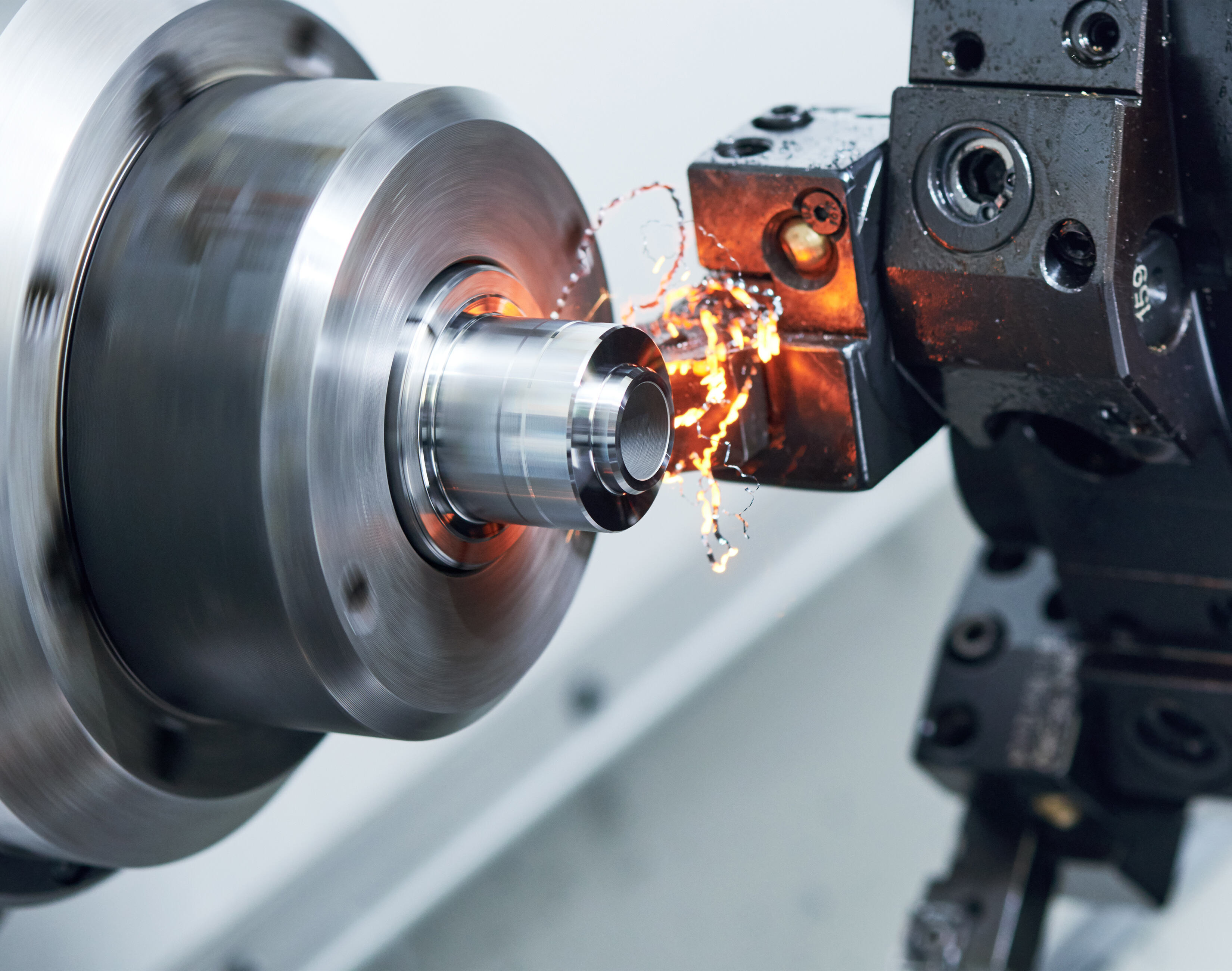

Երբ առաջին անգամ ձեռքով հպվեցի թարմ ֆրեզավորված 3C էլեկտրոնային կազմին՝ նրա մակերեսին, որը փայլում էր ապակու պես, կողերը կատարյալ հարթված, հասկացա, որ մենք ձեռք ենք բերել ոչ միայն «մշակում»։ Մենք ստեղծել էինք ինտեգրացիա դիզայն, որտեղ մակերեսի էսթետիկան և ներքին ամրությունը համատեղվում են անխափան

Խնդրի հասկացում. Էսթետիկայի և գործառույթի հավասարակշռություն

3C (համակարգիչներ, կապ, սպառողական էլեկտրոնիկա) արդյունաբերությունում յուրաքանչյուր արտադրանքի կազմ պատմում է պատմություն՝ ոչ միայն դիզայնի, այլ նաև ճշգրտության մասին

Հաճախորդները հաճախ հարցնում են մեզ.

"Ինչպե՞ս կարող եք մեկ մշակման գործընթացում հասնել հայելու մակարդակի մակերեսային որակի և խիստ կառուցվածքային հանգույցների ճշգրտության?"

Ահա թե որտեղ մտնում է մեր ինտեգրված բարձր փայլուն և կառուցվածքային մշակման լուծումը:

Սովորական ալյումինե կամ մագնեզիումային համաձուլվածքների կազմերից տարբեր, որոնք պահանջում են բազմաթիվ մակերեսային մշակումներ, մենք մշակել ենք մեկ կետում կատարվող ճշգրիտ CNC գործընթաց որն ապահովում է լրացուցիչ փոքրացման և ծածկույթի փուլերի բացակայություն՝ կրճատելով արտադրության ժամանակը 25%-ով՝ պահպանելով ±0,01 մմ թույլատրելի սխալ բարդ երկրաչափությունների դեպքում:

Քայլ առ քայլ. Ինչպես ենք մենք հասնում բարձր փայլուն CNC մշակման

-

Մատերիալների պատրաստում

Մենք սկսում ենք բարձր մաքրության 6063-T6 կամ 7075 ալյումինե կտորներից: Յուրաքանչյուր կտոր ենթարկվում է ուլտրաձայնային մաքրման՝ մակերեսային յուղը հեռացնելու համար՝ ամրացումից առաջ, ինչը բարելավում է վերջնական հետևողականությունը մինչև 18%-ով: -

Գործիքի ճանապարհի օպտիմալացում

Օգտագործելով CAM-ի վերջին ծրագրաշարը, մեր ինժեներները սիմուլյացիա են կատարում գործիքի հետագծերի վրա 5-առանցքային սարքերում:

«Հաստատուն սկալոպ» ստրատեգիան ապահովում է համազանգված մակերեսային կառուցվածք, խուսափելով միկրո քայլի նշումներից՝ նույնիսկ կորացված եզրերի վրա: -

Зеркальная фрезеровка

Հիմնական մասը մեր ադամանդե ծածկույթով գործիքներն են որոնք աշխատում են 40,000 оборот/րոպե-ով: Կոնտրոլվող հովացման ջերմաստիճանի (±0,5 °C) հետ համատեղ այս գործընթացը հասնում է Ra < 0.05 µմ մակերես՝ իսկական հայելու պատվածք, որը հաճախ օգտագործվում է սմարթֆոնների շրջանակներում և պլանշետների հետևի ծածկույթներում: -

Ինտեգրված կոնստրուկտիվ ամրացում

Ներքին փողակներն ու խողովակները մենք անմիջապես տեղադրում ենք նույն CNC ցիկլի ընթացքում, ինչը հանգեցնում է երկրորդային մշակման 30 %-ով կրճատման: Սա ոչ միայն ամրապնդում է կազմը, այլև ապահովում է չափագրական կայունություն հավաքման ընթացքում:

Իրական օրինակ. CNC-ով մշակված կազմ անալոգ ականջների լիցքավորման տուփի համար

Մի հաճախորդ՝ առաջատար սպառողական էլեկտրոնիկայի բրենդից, մի ժամանակ դժվարանում էր լիցքավորման տուփի ծածկույթների լույսի անհամաչափ արտացոլման հետ: Մեր ինտեգրված բարձր փայլուն մշակման գործընթացին անցնելուց հետո , նրանք տեղեկացրին.

-

45 % բարելավում լույսի արտացոլման համաչափության մեջ

-

Լրացուցիչ փոքրացված պոլիրների արժեք մասերի համար 1,80 դոլարով

-

Ցիկլի տևողությունը կրճատվեց 12 րոպեից մինչև 7 րոպե

Մենք արդյունքները վավերացրեցինք եռաչափ մակերեսային սկանավորման և փայլաչափի ցուցմունքների միջոցով՝ իրական տվյալներ, որոնք ապացուցում են գործընթացի հետևողականությունը զանգվածային արտադրության մասշտաբով։

Ինչու՞ կառուցվածքային դիզայնը կարևոր է էսթետիկ մշակման դեպքում

Շատերը ենթադրում են, որ փայլուն մակերեսները մաքուր դեկորատիվ են: Փաստորեն, մակերեսը և կառուցվածքը ազդում են մեկը մյուսի վրա: Անգամ փոքր-ինչ անհավասար փողոց կամ ամրացման անցք կարող է դեֆորմացնել արտացոլումները: Ուստի մեր դիզայներները օգտագործում են վերջավոր տարրերի անալիզ (ՎՏԱ) ճնշման տակ դեֆորմացիան կանխատեսելու և մշակմանից առաջ պատերի հաստությունը կարգավորելու համար:

Նախագծման վաղ փուլում մեխանիկական մոդելավորումը և օպտիկական գնահատումը ինտեգրելով՝ մենք հասել ենք բնակարանի հարթության ±0,03 մմ 120 մմ լայնությամբ — կարևոր է այնպիսի խոշոր 3C սարքերի համար, ինչպիսիք են պլանշետները կամ մոնիտորները:

Գնորդների և ինժեներների համար ստանդարտ տեխնիկական տեղեկություններ

| Հատկություն | Տեխնոլոգիական առավելություն | Չափելի արդյունք |

|---|---|---|

| Ալմասե գործիքի հայելային մշակում | Հեռացնում է պողպողը | Ra < 0.05 µմ |

| Ինտեգրված փողային կտրում | Բարձրացնում է կոնստրուկտիվ կոշտությունը | +20% կոշտություն |

| CAM գործիքային հետևի սիմուլյացիա | Կանխում է մակերևույթային գծերը | 100% տեսողական հետևողականություն |

| Ջերմաստիճանից կախված հեղուկ հովացման համակարգ | Կանխում է ջերմային դեֆորմացիան | ±0,01 մմ թույլատրելի շեղում |

Ապագայի նայվածք. դեպի կայուն մշակում 3C բաղադրիչների համար

Մենք նաև շարժվում ենք դեպի էկոլորտ կտրման հեղուկներ և վերամշակվող ալյումինե նյութեր , համապատասխանեցնելով կանաչ արտադրության նպատակներին: Մառախուղ-սառեցման և թեփ-վերամշակման համակարգերի օգտագործմամբ մենք 40 %-ով կրճատել ենք հեղուկ թափոնները՝ առանց վերջնական մշակման որակին հարված հասցնելու:

ՀՏՀ. Հաճախ տրվող հարցեր

Հ. Կարո՞ղ են բարձր փայլուն մակերեսները դիմանալ անոդացմանը կամ ներկմանը հետո

Պատասխան. Այո: Մեր գործընթացը պահպանում է փայլի համասեռությունը անոդացումից կամ PVD-ից հետո: Մենք նախնական փորձարկում ենք ծածկույթի կպչունությունը՝ օգտագործելով ASTM D3359 ստանդարտը:

Հ. Ո՞րն է նվազագույն պատի հաստությունը, որի դեպքում դուք կարող եք մշակել առանց դեֆորմացիայի

Պատասխան. Ալյումին 6063 կազմույթների դեպքում ստանդարտ ամրացման ճնշման դեպքում պահպանում ենք 0,6 մմ նվազագույն պատի հաստություն՝ արտադրության փորձարկումներով հաստատված:

Հ. Արդյոք դուք առաջարկում եք նմուշից մինչև սերիական արտադրություն աջակցություն

Պատասխան. Իհարկե: Մեր ներքին արագ նմուշայնացման գիծը հնարավորություն է տալիս ստանալ ֆունկցիոնալ նմուշներ 48 ժամվա ընթացքում՝ մասշտաբային արտադրության անցնելուց առաջ:

.

PFT Precision, ձեր վստահելի գործընկերը պատվիրված CNC մշակման մեջ

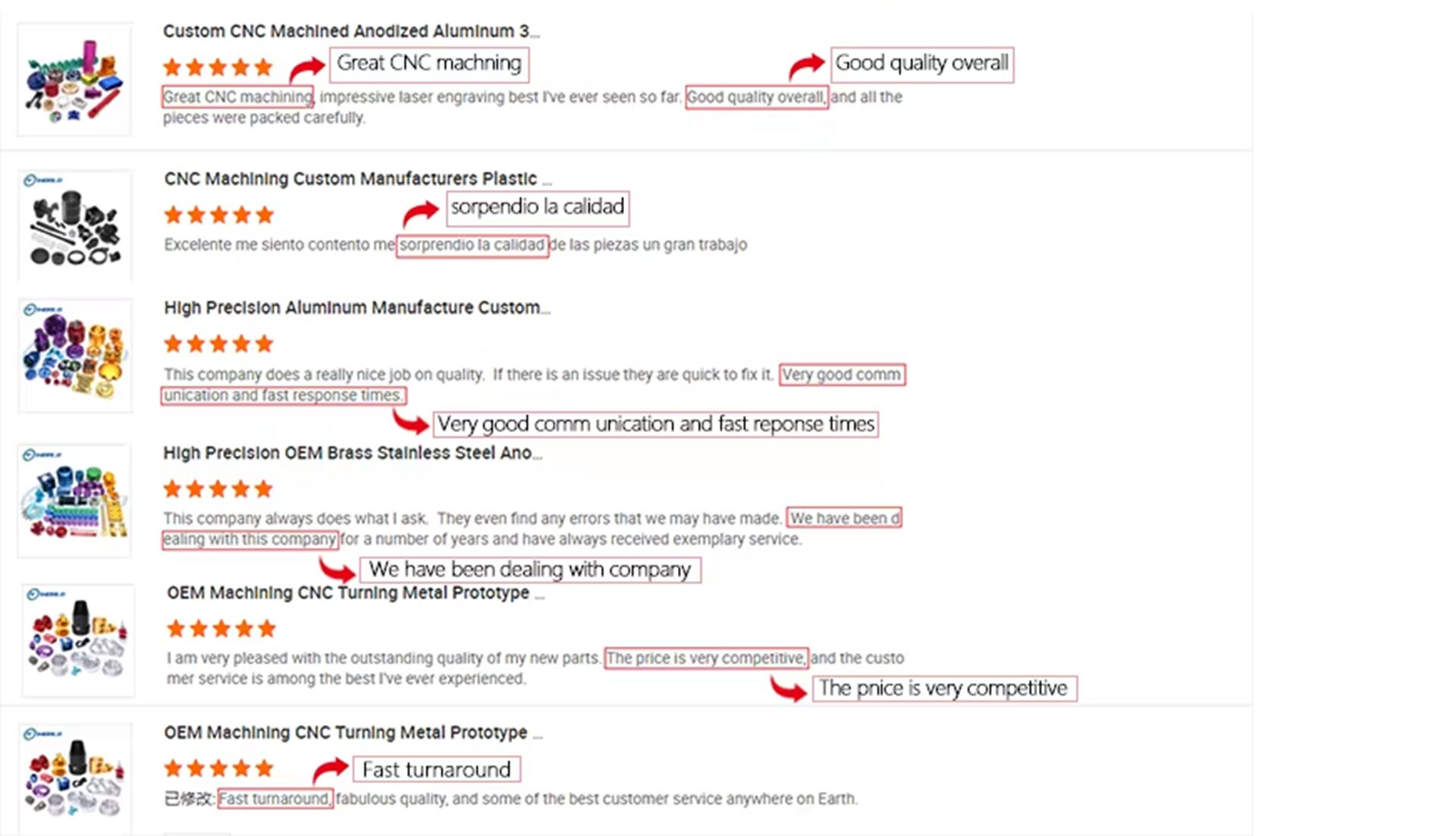

Որպես պատվիրված CNC մշակման մասերի և բաղադրիչների առաջատար մատակարար, PFT Precision-ը մասնագիտացած է սկզբնական փորձարկումների և ֆրեզային մշակման բարձրորակ մետաղական նյութերի վրա: Մենք մատակարարում ենք ճշգրիտ նախագծված արտադրանքներ՝ հարմարեցված տարբեր ոլորտների յուրահատուկ պահանջներին: Մեր հավատարմությունը բարձր որակին հնարավորություն է տվել մեզ հաստատել մեզ որպես շուկայի առաջատար CNC արտադրողներից մեկը:

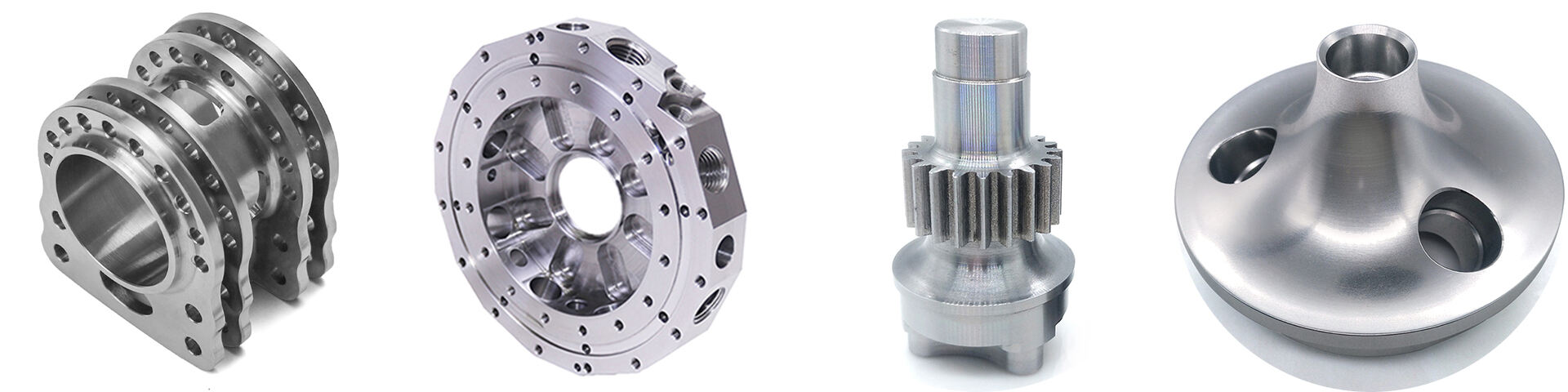

Մեխանիզմի առանցք: 3,4,5,6

Թողունակություն +/- 0.01 մմ

ՍPECIAL Տարածքներ: +/-0.005մմ

Մակերևույթի հատկություն: Ra 0.1~3.2

Մատակարարման կարողություն: 300000Կտոր/Ամիս

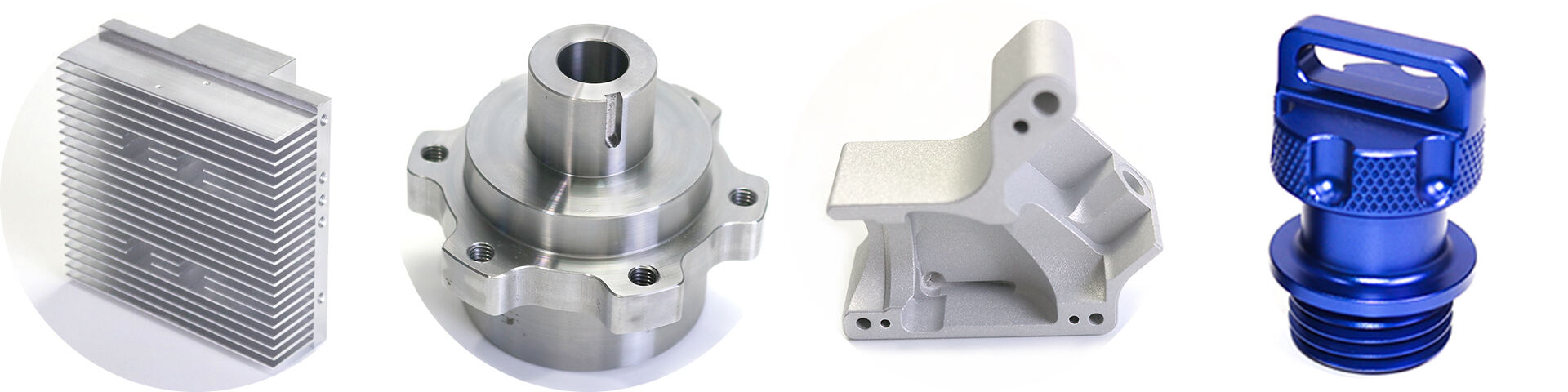

Առանձնացված ճշգրիտ մասեր

Հաշվետվություն Գարանտիա:

Հաստատուն հետապատolgություն послe-վաճառք

Մենք պարծենում ենք նրանով, որ մեր CNC մշակման ծառայությունների համար ստացել ենք մի քանի արտադրության վկայականներ, ինչը ցույց է տալիս մեր նվիրումը որակի և հաճախորդների բավարարմանը: Մեր թիմը հետևում է խիստ որակի վերահսկման ընթացակարգերին՝ ապահովելով, որ արտադրած յուրաքանչյուր մասը համապատասխանում է որակի և ճշգրտության ամենաբարձր չափանիշներին

|

Մշակում

|

CNC چرخان, CNC կորում, լեզուցի կտրում, ծագում, պտույտ, սیրեն կտրում, դրոշք, էլեկտրոնային հաղորդակցության մեխանիզմ (EDM), մոլդավորում

|

|||||||

|

Նյութեր

|

Ալյումինիում՝ 2000 շարք, 6000 շարք, 7075, 5052 և այլն

|

|||||||

|

Շիկացված պողպատ՝ SUS303, SUS304, SS316, SS316L, 17-4PH և այլն

|

||||||||

|

Պողպատ՝ 1214L/1215/1045/4140/SCM440/40CrMo և այլն

|

||||||||

|

Երկաթ: 260, C360, H59, H60, H62, H63, H65, H68, H70, Բրոնզ, Մեդ

|

||||||||

|

Տիտան: F1-F5 գրադացիոն

|

||||||||

|

Պլաստմասսա՝ Acetal/POM/PA/Նայլոն/PC/PMMA/PVC/PU/Ակրիլ/ABS/PTFE/PEEK և այլն

|

||||||||

|

Մակերևույթի մշակման

|

Օքսիդացված, Փոշի փչող մաքրում, Ծանրագրություն, PVD պլատինապատում, Ցինկ/Նիկել/Քրոմ/Տիտան պլատինապատում, Խոզանակով մաքրում, Ներկում, Փոշիային ծածկույթ, Պասսիվացում, Էլեկտրաֆորեզ, Էլեկտրական փայլակ, Շեղատ, Լազերային/Խորագրություն/Խորակոփում և այլն

|

|||||||

|

Համոզագույնություն

|

±0.002 ~ ±0.005 մմ

|

|||||||

|

Մակերեսի դաժանություն

|

Մին Ra 0.1~3.2

|

|||||||

Վստահեք փորագրման մեջ փորագրման մասնագետներին

Ալյումին

Եղցանիքի արծաթ/Արծաթ/Տիտան դաշնակցություն

1214L/1215/1045/4140/SCM440/40CrMo և այլն

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B և այլն

Ծաղիկ/Կոպր

Պլաստիկ

CNC մեխանական մասերի մակերեսի -ENDASNAVORCES.

Մանրամասն նկարներ (PDF/STEP/IGS/DWG...), ներառյալ որակը, առաքման ժամկետը, նյութերը, որակը, քանակը, մակերեսային մշակումը և այլ տեղեկություններ