Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

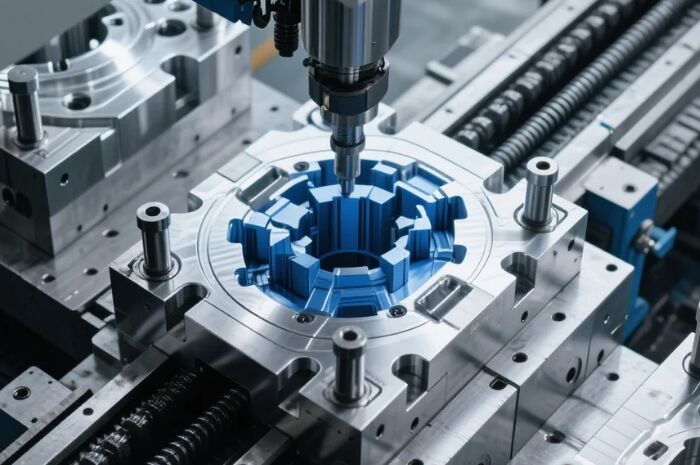

When precision engineering meets relentless innovation, you get a partner dedicated to transforming your manufacturing vision into flawless reality. As a leading injection mould and die cast tooling manufacturing specialist, we blend cutting-edge technology with decades of expertise to deliver tools that redefine industry standards. Here’s why global clients trust us for mission-critical projects.

Our facility houses state-of-the-art Makino high-speed CNC machines, Wire-Cutting EDM systems, and 3D printing capabilities for conformal cooling channels.Unlike conventional tooling, our additive manufacturing processes reduce cycle times by 35% and eliminate defects like sink marks.This isn’t just machinery – it’s your guarantee of faster production, lower costs, and superior part quality.

Every tool undergoes a 7-stage validation process under our ISO 9001-certified system . From material selection (we use Uddeholm tool steel with PVD coatings for wear resistance) to final inspection, we deploy real-time thermal monitoring and AI-driven analytics.Result? Near-zero tolerance margins and tools that outlast industry averages by 40%.

Whether you need gas-assist moulds for automotive components or multi-cavity dies for medical devices, our portfolio spans:

Forget juggling multiple vendors. Our one-stop service covers:

While competitors focus on isolated processes, we integrate sustainable innovation. Example: Our conformal cooling tools cut energy use by 22% while boosting output.Client testimonials consistently highlight:

"30% faster time-to-market versus previous suppliers, with zero rework needed" – Automotive Tier-1 Client

Searching for " precision die cast tooling in Shenzhen "? Our location-optimized solutions combine regional responsiveness with international quality. We’re not just manufacturers – we’re your strategic partners in growth.

Explore case studies of our tools in action or request a free DFM consultation. With 50+ engineers and a track record of 99.6% on-time delivery, we turn complexity into competitive advantage.

Contact us today →E-mail:[email protected]

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog