룽강 구역 핑후 촌, 후민 산업 단지 49동

일요일 휴무

제조업에 가장 큰 변화를 가져온 기술은 아마도 3D 프린팅일 것입니다. 이 기술은 컴퓨터를 사용하거나 특수 기술인 3D 프린터를 통해 세 가지 차원의 물체를 설계할 수 있게 해줍니다. 3D 프린팅에서는 상상할 수 있는 거의 모든 것이 만들어질 수 있습니다! 이를 통해 이전에는 불가능했던 방식으로 장난감, 도구 및 기타 다양한 물건들을 만들 수 있습니다.

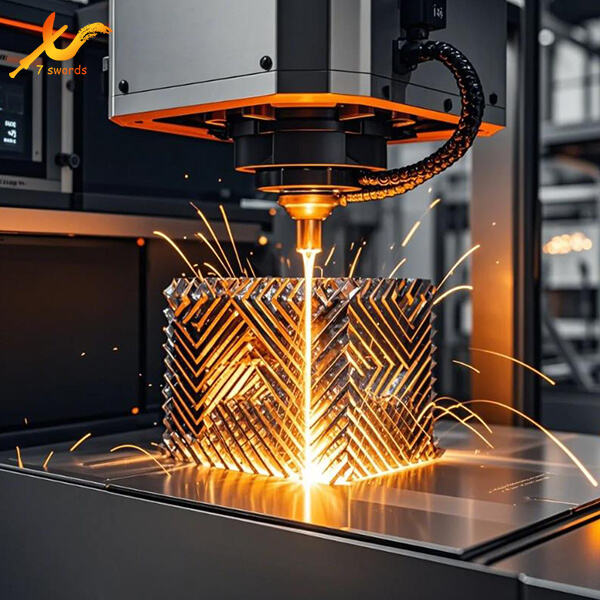

최근 몇 년간은 새로운 유형의 3D 프린터가 등장한 시기였습니다. 이를 금속 3D 인쇄라고 합니다. 이 혁신적인 기술 덕분에 우리는 대칭성을 위해 단지 플라스틱이 아닌 다양한 형태의 금속을 사용할 수 있게 되었습니다. 금속 3D 인쇄 기술은 물体制작 가능성을 크게 확대했습니다. 이제 우리는 더 두껍고 견고한 제품을 만들 수 있어 여러 방식으로 활용할 수 있습니다.

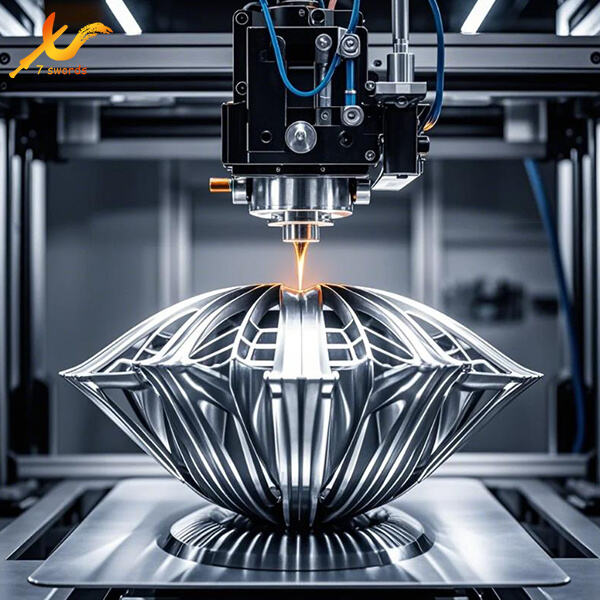

또한, 금속 3D 프린팅은 더 복잡한 형태와 디자인을 제조할 수 있도록 해주어 완전히 새로운 단계로 나아갑니다. 전통적인 제조 방식에서는 복잡한 형태를 제작하는 것이 일반적으로 매우 어렵고 시간이 많이 걸립니다. 그러나 금속 3D 프린팅을 사용하면 복잡하고 세부적인 독특한 형태를 훨씬 더 쉽게 만들 수 있습니다! 이는 제조업체가 단순히 더 가볍고 강한 부품뿐만 아니라 최종 사용에서 더 효율적인 부품을 만들 수 있게 합니다.

전통적인 제조 방식에는 한계가 있으며, 금속 3D 프린팅은 이러한 한계를 깨고 있습니다. 이는 과거에 주조하기 extremely 어려웠거나 사실상 불가능했던 것을 생산할 수 있게 하는 기반이 됩니다. 실제로 이제 옛 방식으로는 만들기 불가능했던 매우 복잡한 디자인의 제품을 만들 수 있게 되었습니다. 이는 혁신과 창의적인 해결책의 다양한 길을 열어주었습니다.

메탈 3D 프린팅의 또 다른 멋진 측면은 복잡한 내부 구조를 만들 수 있다는 점입니다. 전통적인 제조 기술에서는 내부 패턴이 있는 물체를 만드는 것이 상당히 어렵습니다. 그러나 메탈 3D 프린팅은 안쪽에 빈 공간이 있는 물체를 만들 수 있게 해줍니다. 이러한 빈 공간 안에 다른 재료를 포함시킬 수도 있어, 새로운 제품 디자인을 만드는 데 더 많은 기회를 제공합니다.

이것은 메탈 3D 프린팅이 다양한 합금을 통해 적용될 수 있는 매우 유연한 기술인 이유 중 하나입니다. 각 금속은 고유한 특성을 가지고 있어, 다양한 용도로 사용하는 데 이점이 됩니다. 예를 들어, 티타늄은 무게 대비 강도가 매우 높아 항공우주 산업에서 비행기 부품을 만드는 데 여러 응용이 있습니다. 스테인레스는 녹슬거나 부식되지 않으며 얼룩이 가지 않아 안전하고 신뢰할 수 있기 때문에 수술 도구와 의료 장치에 사용됩니다.

메탈 3D 프린팅은 지난 십 년간 급격히 발전해 온 산업 내에서 매우 빠르게 변화하는 분야입니다. 많은 조직들이 이 기술을 도입하기 시작했으며, 우리는 몇 가지 놀라운 새로운 솔루션들이 등장하는 것을 목격하고 있습니다. 항공우주, 자동차, 의료, 심지어 예술 같은 다양한 산업들이 이 기술을 활용하고 있습니다. 이제 사람들은 이 기술 덕분에 이전에는 상상할 수 없었던 것들을 만들 수 있게 되었습니다.