Precision in Progress: CNC Milled Parts Reshaping the Future of Professional Manufacturing

In a world where precision, speed, and innovation define competitive advantage, CNC milled parts are emerging as a driving force behind the evolution of professional manufacturing. From aerospace and defense to medical devices and consumer electronics, companies across industries are increasingly turning to CNC milling technology to meet rising demands for accuracy, consistency, and scalability.

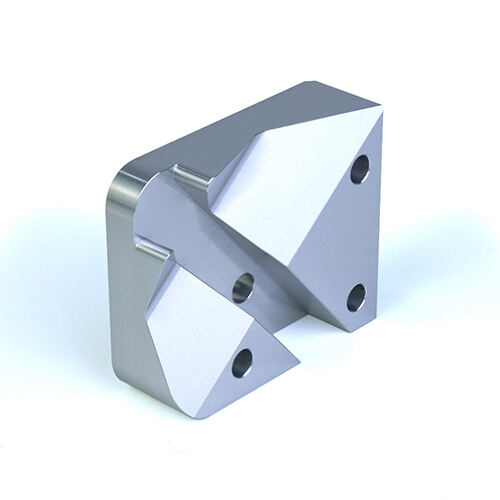

Computer Numerical Control (CNC) milling—a process where automated cutting tools carve complex shapes from solid blocks of metal or plastic—has transformed the way manufacturers produce high-performance components. Today, CNC milled parts are synonymous with tight tolerances, repeatable quality, and shortened production cycles.

Industry Growth Driven by Demand for Precision

According to a recent market analysis by Global Tech Insights, the CNC machining market is projected to reach over $100 billion by 2028, with milled parts accounting for a significant share of that growth. Industry experts attribute this surge to increasing complexity in product design, along with a rising need for lightweight, high-strength materials that require advanced machining capabilities.

Professional Manufacturing: Setting a Higher Standard

Professional manufacturing firms are doubling down on CNC investments, equipping their facilities with multi-axis milling machines, automated inspection systems, and advanced CAM (Computer-Aided Manufacturing) software. This evolution has not only improved lead times but also raised the bar for product quality across industries.

Key benefits driving the adoption of CNC milled parts include:

Precision Engineering: Capable of achieving tolerances within ±0.001 mm, CNC milling allows for seamless part integration in critical applications.

Material Flexibility: From aerospace-grade aluminum to engineering plastics, CNC machines handle diverse materials without compromising on quality.

Design Complexity: Multi-axis machines enable the production of geometrically intricate parts that were once considered unmanufacturable.

Applications Across Every Industry

From customized medical implants to aerospace engine housings, CNC milled parts play an integral role in product development and performance. In the electric vehicle (EV) sector, manufacturers rely on milled components for battery enclosures, cooling systems, and structural supports—balancing strength with lightweight design.

Looking Ahead: Automation and Sustainability

As manufacturing heads toward Industry 4.0, CNC milling is becoming smarter and more sustainable. Integration with AI-powered monitoring systems, real-time data analysis, and eco-conscious machining strategies are reshaping the production floor.

Sustainability initiatives are also influencing CNC practices. Companies are adopting coolant recycling systems, minimizing waste through precise cutting, and optimizing tool paths to reduce energy use—all while continuing to deliver top-tier CNC milled parts.