Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Introducing, the Swords Precision High Precision Manufactured Parts Milling Drilling Machine, the ultimate solution for all your custom product robot engineering needs. Our CNC machining services are here to cater to the growing demand for precision parts in various industries.

What sets Swords Precision apart from the competition is our commitment to delivering top-notch products that meet and exceed our customers' expectations. Our state-of-the-art milling and drilling machine is capable of producing high-precision parts with unparalleled accuracy and consistency.

Whether you are in need of custom parts for robotics, automation, automotive, aerospace, or any other industry, our team of expert engineers and technicians are here to help. We understand that each project is unique, which is why we offer personalized solutions tailored to your specific requirements.

At Swords Precision, we believe that quality is key. That is why we only use the highest quality materials and advanced manufacturing techniques to ensure that our products are of the highest standard. Our CNC machining services are second to none, delivering precise results every time.

With our High Precision Manufactured Parts Milling Drilling Machine, you can rest assured that your custom products will be produced with the utmost accuracy and attention to detail. Whether you need complex geometries, tight tolerances, or intricate designs, we have the capabilities to bring your vision to life.

Our team is dedicated to providing exceptional customer service and support throughout the entire manufacturing process. From initial consultation to final delivery, we are here to guide you every step of the way. We pride ourselves on our ability to meet tight deadlines and deliver quality products on time, every time.

If you are in need of high precision manufactured parts for your next project, look no further than Swords Precision. Our CNC machining services are the perfect solution for all your custom product robot engineering needs. Contact us today to learn more about how we can help bring your ideas to reality

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, 3D Printing, Rapid Prototype, Moulds etc |

|||||||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

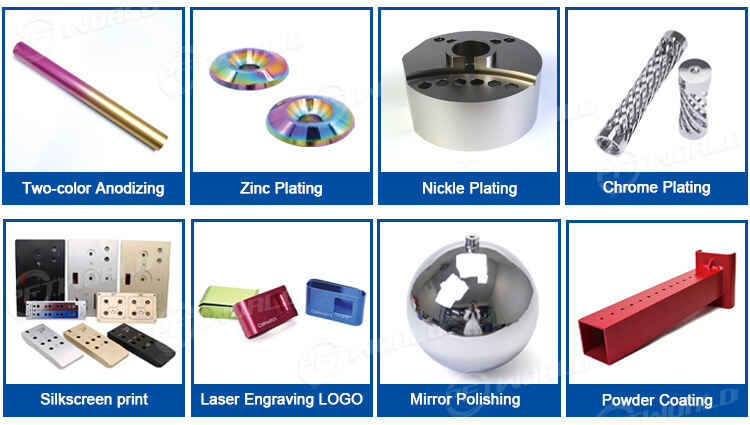

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

+/-0.01 ~ 0.005mm |

|||||||

Surface Roughness |

Min Ra 0.1~3.2

|

|||||||

CERTIFICATE |

||||||||

1. Are you a manufacturer or a trading company

We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports

2. How to get a quote3. Can I get a quotation without drawings

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation

4. Can you provide samples before mass production

Of course, the sample fee is necessary. If possible, it will be returned during mass production

5. What is the delivery date

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks

6. How do you control quality

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog