Swords Precision offers top-quality Mechanical Parts CNC Machining Aluminum Guitar Pedal Enclosures in a stunning PVD Gold finish. These enclosures are designed with precision engineering to provide a durable and reliable housing for your guitar pedals

Crafted from high-grade aluminum, these enclosures are lightweight yet strong, ensuring they can withstand the rigors of the road. The CNC machining process guarantees a perfect fit and finish, with smooth edges and precise dimensions for a professional look

The PVD Gold coating adds a touch of elegance to your Pedal board, giving it a luxurious appearance that will stand out on stage. The gold finish is not only eye-catching but also provides added protection against corrosion and wear, ensuring your pedals look as good as they sound for years to come

Swords Precision's engineering design services ensure that every aspect of these enclosures is thoughtfully considered. From the placement of mounting holes to the accessibility of internal components, the design is optimized for ease of use and functionality. Whether you're a seasoned musician or a DIY enthusiast, you'll appreciate the attention to detail that goes into every Swords Precision product

In addition to their aesthetic appeal, these enclosures are also practical and versatile. The durable aluminum construction provides excellent shielding against electromagnetic interference, helping to minimize noise and maintain the integrity of your signal. The smooth surface finish allows for easy customization, whether you choose to paint, engrave, or add decals to personalize your pedals

Whether you're a musician looking to protect your valuable effects pedals or a builder in need of high-quality enclosures for your custom pedal projects, Swords Precision's Mechanical Parts CNC Machining Aluminum Guitar Pedal Enclosures in PVD Gold are the perfect solution. With their combination of durability, elegance, and precision engineering, these enclosures are sure to exceed your expectations and elevate your Pedal board to the next level

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including metals, plastics and composites

Machinery Axis:

3,4,5,6Tolerance:

+/- 0.01mm

Special Areas :

+/-0.005mm

Surface Roughness: Ra

0.1~3.2 Supply Ability:

300,000 Piece/Month

OEM&ODMCustomized Precision Parts

1-Piece minimum order

3-Hour quotation

Samples: 1-3Days

Lead time:

7-14 Days

QC team, inspectionReport Guarantee:

Lifetime After-Sales Service Certificate:Medical, Aviation, Automobile

ISO13485, IS09001, AS9100, IATF16949

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining EDM, Injection Molding, 3D Printing, Rapid Prototype, Moulds etc |

|

|

|

|

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|

|

|

|

|

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

|

|

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

|

|

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

|

|

|

|

Titanium: Grade F1-F5 |

|

|

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

|

|

|

|

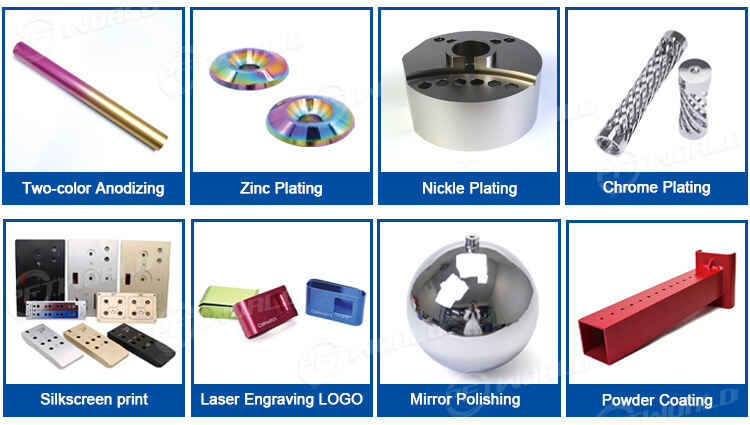

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|

|

|

|

|

+/-0.01 ~ 0.005mm |

|

|

|

|

|

Min Ra 0.1~3.2

|

|

|

|

|

CERTIFICATE |

|

|

|

|

|

Cutting-edge Precision for Your Manufacturing Needs

Trust the Experts in CNC Machining

Aluminum

Tolerance: +/- 0.01~+/-0.005mm

Material:2024, 5083, 6061, 6063, 7075, etc

Surface treatment: Oxidation, electrophoresis, sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc

Stainless Steel/Steel/Titanium Alloy

Tolerance: +/- 0.01~+/-0.005mm

Material:

SUS303, SUS304, SS316, SS316L, 17-4PH, etc

1214L/1215/1045/4140/SCM440/40CrMo, etc

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B etc

Surfacetreatment: Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling, shot peening, etc

Brass/Copper

Tolerance: +/- 0.01~+/-0.005mm

Material: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, C11000, C12000, C22000, C26000, C28000, C36000 etc

Surface treatment:Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment, pickling, shot peening, etc

Plastic

Tolerance: +/- 0.01~+/-0.005mm

Material: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc

Surface treatment:Spraying, sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc

CNC Machined Parts Surface Treatment

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc

(2) Chemical surface treatment: bluish blackening, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc

(3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc

(4) Modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc

Precision meets performanceOur CNC machining services ensure the highest level of machinability for all your complex part needs

20+Years CNC Machining

Supply Ability:300,000Pce/Month

Machinery Axis:3,4,5,6

Tolerance:+/-0.01~0.005mm

Certification:

ISO9001, AS9100D, ISO13485, ISO45001, IATF16949, ISO14001, ROSH, CE etc

We are engaged in precision mould, CNC turning parts, CNC milling parts. Our products are mainly used for industrial equipments and medical equipments. We can make products with material of stainless steel, steel alloy, copper, aluminum, PEEK, bronze alloy, nylon, PTFE etc. The surface treatment we can handle is anodize, black oxide, powder coating, high polishing and plating. In order to make sure the critical dimensions, we import our machines from USA and Japan. The minimum tolerance we can make is 0.005-0.01millimetre. Our engineers are quite experienced and can supply OEM&ODM service or can give some advices when you need. Our works are trained and follow ISOstandard. Choose us PERFECT, we will exceed your expectation. So if anything we can help or any further information you need, please don't hesitate to contact us

Welcome to a world where precision meets excellence, where our machining services have left a trail of satisfied customers who couldnt help but sing our praises. We are proud to showcase the resounding positive feedback that speaks volumes about the exceptional quality. reliability. and craftsmanship that define our work. This is just a part of buyer feedback, we have more positive feedback, you are welcome to learn more about us

1. Are you a manufacturer or a trading company We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports

2. How to get a quote

Detailed drawings PDF/STEP/IGS/DWG, including quality, delivery date, materials, quality, quantity, surface treatment and other information

3. Can I get a quotation without drawings

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation

4. Can you provide samples before mass production

Of course, the sample fee is necessary. If possible, it will be returned during mass production

5. What is the delivery date

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks

6. How do you control quality

(1) Material Inspection - Check material surfaces and approximate dimensions

(2) First inspection of production - ensure critical dimensions in mass production

(3) Sampling inspection - check the quality before delivery to the warehouse

(4) Preshipment inspection - 100% inspection by QC assistant before shipment

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week