Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Home / Products / Sheet Metal / Cutting

Swords Precision

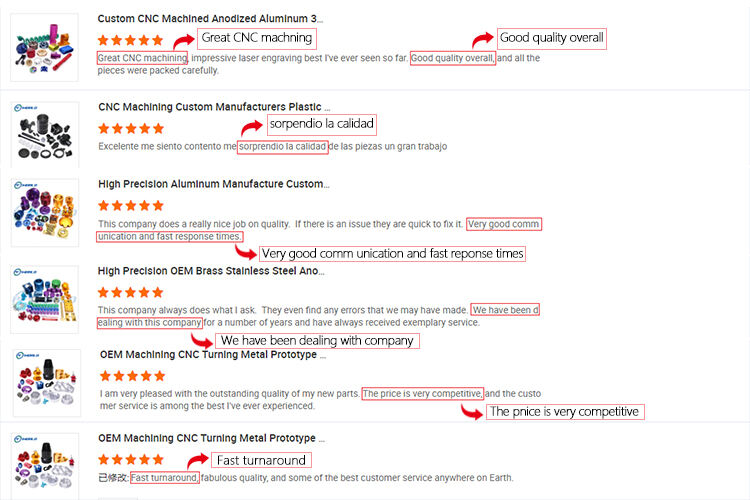

Introducing Swords Precision's top-of-the-line OEM cutting parts products machine services box welded bending stamping punching CNC custom sheet metal fabrication enclosure. Our products are designed to precision and durability, ensuring that your projects are completed with the highest level of quality.

Our cutting parts products are made with the latest technology in order to provide you with precise cuts every time. The machine services we offer are top-notch, guaranteeing that your tools will be performing optimally at all times. Our Swords Precision box welded bending services are designed to meet all of your shaping needs, while our stamping and punching capabilities ensure that your products will be manufactured quickly and efficiently.

At Swords Precision, we take pride in offering custom sheet metal fabrication services that are second to none. Whether you need a simple design or a complex enclosure, our team of experts is here to bring your vision to life. Our CNC capabilities allow us to create intricate designs that will set your project apart from the rest.

When it comes to sheet metal fabrication enclosures, Swords Precision has you covered. Our products are built to last, ensuring that your equipment is protected at all times. Whether you need a small enclosure or a large-scale solution, our team is here to provide you with the best possible options for your needs.

With Swords Precision, you can trust that you are receiving top-quality products and services every time. Our team is dedicated to delivering exceptional results that exceed your expectations. When you choose Swords Precision, you are choosing a partner that will work with you to ensure that your project is completed with the highest level of precision and expertise.

Don't settle for anything less than the best when it comes to OEM cutting parts products machine services box welded bending stamping punching CNC custom sheet metal fabrication enclosures. Choose Swords Precision for all of your fabrication needs, and experience the difference that quality and precision can make in your projects.

High Quality CNC OEM Machining Supplier custom sheet metal enclosure

|

||||||||

Materials |

Metal: Titanium, Aluminum, Stainless steel & Steel, Brass |

|||||||

Plastic: POM, PEEK, ABS, Nylon, PVC, Acrylic, etc. |

||||||||

Processing |

CNC turning, CNC milling, CNC turn-milled, Laser cutting |

|||||||

Surface Treatment |

Powder Coated, (Ordinary & Hard) Anodized, Electropolished & Polished, Plating, Bead Blasted, Heat treatment, Passivate, Black oxidate, Brushing, Laser engraving |

|||||||

Tolerance |

+/-0.005mm |

|||||||

Lead Time |

1-2 weeks for samples, 3-4 weeks for mass production |

|||||||

Quality Assurance |

ISO9001: 2015, SGS, RoHS, TUV |

|||||||

Drawing Accepted |

Solid Works, Pro/Engineer, Auto CAD(DXF, DWG), PDF |

|||||||

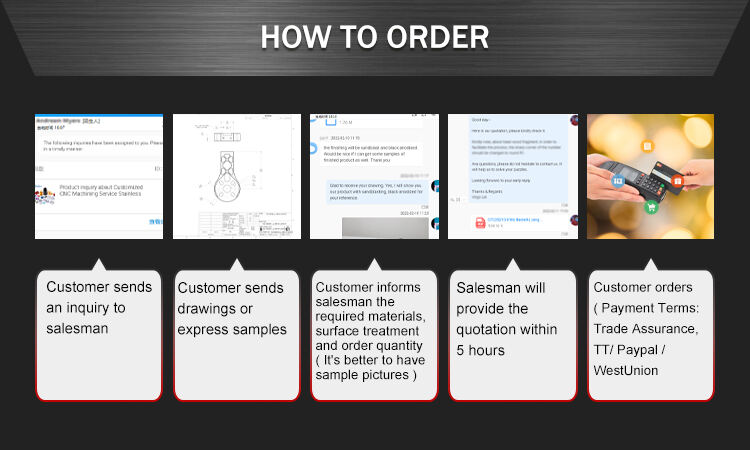

Payment Terms |

Trade Assurance, TT, Paypal, WestUnion |

|||||||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog