Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

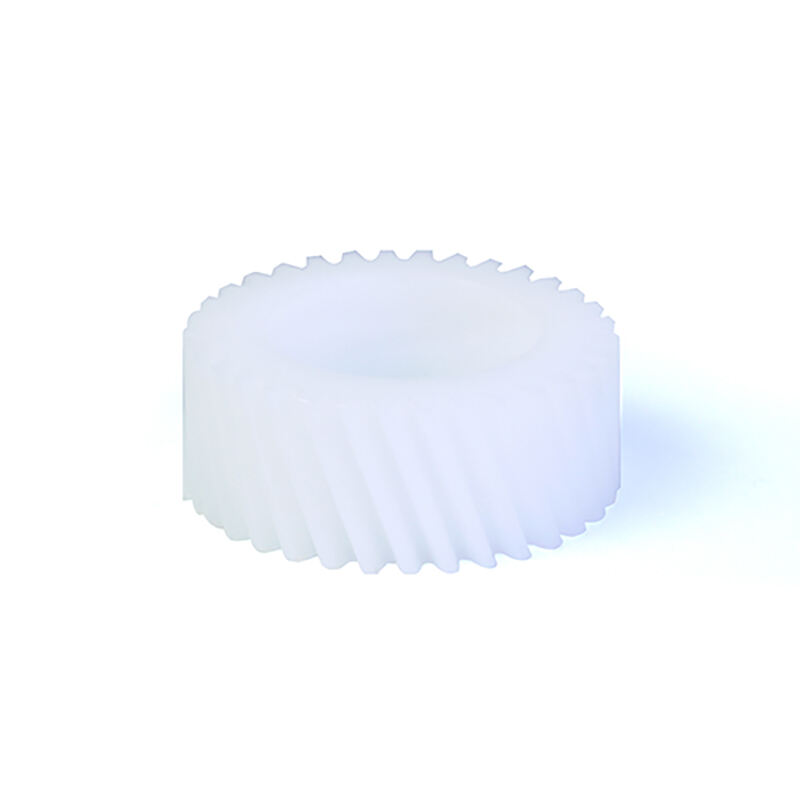

If you're designing parts for smooth, quiet, and wear-resistant gear systems, nylon might be exactly what you're looking for. And when it comes to making nylon parts with tight tolerances, CNC turning is one of the most efficient and reliable ways to get the job done.

First off, nylon isn't just one thing. It's a family of engineering plastics, but for gears, Nylon 66 (PA66) and Cast Nylon (PA6) are the usual stars. Here’s why they rock for moving parts:

• Built-In Lubricity: This is the big one. Nylon has a naturally low coefficient of friction. It's slippery all on its own, meaning parts can slide and mesh with less resistance and without always needing extra grease or oil. This is huge for clean applications like food processing or medical equipment.

• Tough as Nails: It's shock-absorbent and has great fatigue resistance. A nylon gear can take the constant stopping, starting, and reversing that would quickly wear out or crack a metal gear.

• Quiet Operation: Plastic meshing with plastic or metal is simply quieter than metal-on-metal. If you're trying to reduce noise in your assembly, nylon is a fantastic choice.

• Lightweight: It's about 1/7th the weight of steel. Reducing rotating mass can lead to energy savings and less wear on supporting components like bearings and shafts.

CNC turning is a subtractive manufacturing process where a cutting tool moves along a rotating workpiece. It’s perfect for creating symmetrical parts like pulleys, bushings, spacers, and of course, round gear blanks.

Here’s why CNC turning is a strong choice for machining nylon gears:

• Precision: CNC machines can hold tight tolerances, even with soft materials like nylon.

• Speed: Once your program is set up, parts can be turned quickly and consistently.

• Repeatability: Whether you’re making 10 parts or 10,000, CNC keeps everything uniform.

• Minimal waste: With optimized tool paths, there’s less material waste.

When you're designing gears that will be CNC-turned from nylon, here are a few things to keep in mind:

• Avoid sharp corners. Nylon flows better with rounded internal features, reducing stress concentrations.

• Account for thermal expansion. Nylon can expand more than metals—factor that into your tolerances.

• Use proper support during machining. Because nylon is softer, it can flex. Using steady rests and sharp tools helps prevent warping or chatter.

• 3D printer components

• Medical devices

• Food processing equipment

• Robotics and automation

• Conveyor systems

If you're designing a system that requires smooth, quiet, and reliable motion without the cost and wait of custom tooling, CNC-turned nylon gears are a brilliant solution. They offer a unique blend of performance, speed, and precision that's hard to beat.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog