Edifício 49, Parque Industrial Fumin, Vilarejo de Pinghu, Distrito de Longgang

Domingo Fechado

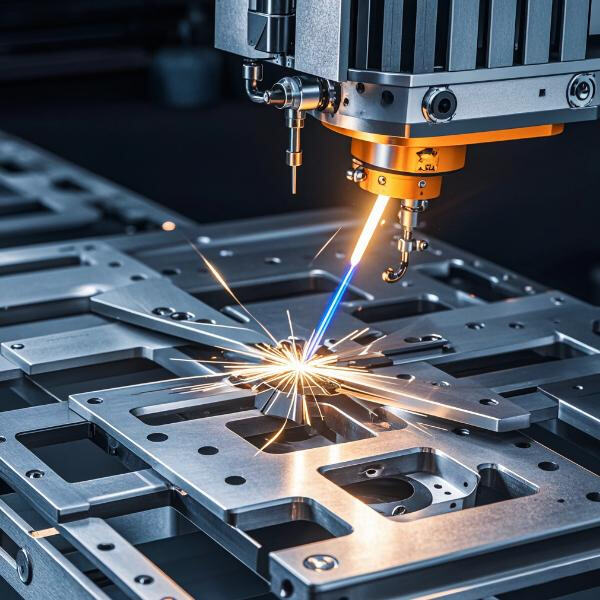

Peças de precisão aeroespacial é um processo incrível que utiliza um feixe de laser de alta potência para cortar diversos materiais. É como usar uma varinha para cortar! Uma das empresas que implementa essa tecnologia é a Swords Precision, que fabrica alguns itens impressionantes. Neste artigo, exploraremos o corte a laser, seus princípios de funcionamento e seu papel na transformação do processo de design de produtos em várias indústrias.

Há muito tempo, o corte a laser existe no mundo. O primeiro laser real foi criado em 1960, na verdade! Isso significa que cientistas e engenheiros têm trabalhado muito com lasers ao longo dos anos. Os lasers se desenvolveram em dispositivos muito poderosos ao longo das décadas. Hoje, lasers podem cortar através de metal, madeira, plástico ou tecido. Isso torna esse trabalho de design simples porque o feixe de laser é realmente preciso. Ele cria formas e padrões bonitos que são difíceis de criar usando ferramentas de corte tradicionais, beneficiando artistas e designers.

Peças CNC de Alumínio é realmente muito bom por um grande motivo: a precisão. Usando ferramentas de corte padrão, formas e designs são difíceis de alcançar, mas o feixe de laser pode cortar formas e criar designs. Graças a essa precisão, peças de máquinas personalizadas são criadas com encaixe perfeito, criações de joias elegantes com um visual especial ou até pequenos modelos de edifícios com muitos detalhes.

O corte a laser também tem a vantagem de ser mais rápido do que outras técnicas de corte. Com a capacidade de fatiar materiais em um ritmo, os trabalhadores podem fabricar mais em menos tempo. Isso é extremamente crucial para empresas que precisam produzir milhares de produtos em um período relativamente curto. O corte a laser permite que as empresas criem produtos de alta qualidade mais rapidamente e com menos custo.

Os lasers são poderosos, e se mal utilizados, podem ser prejudiciais. O clarão do feixe laser pode danificar os olhos se encarado diretamente e uma aproximação próxima pode queimar sua pele. É por isso que SEMPRE seguir as diretrizes de segurança ao usar um cortador a laser é de extrema importância. A segurança é uma parte importante do que fazemos na Swords Precision. Supervisão dos Funcionários no Uso — Garantimos que todos os nossos funcionários entendam como usar o equipamento de forma segura e cumpram as diretrizes de segurança.

Também fazemos pesquisas com clientes para saber o que eles realmente precisam, e isso nos ajuda a garantir que nossos produtos sejam artísticos além de funcionais. Em alguns casos, o cliente sabe o que está procurando e faremos esforços para adotar esses movimentos. Essa colaboração entre designers e clientes leva aos melhores produtos que as pessoas realmente apreciam.

Como as máquinas de corte a laser são mais rápidas do que os processos de corte anteriores, cortamos centenas de itens rapidamente e a preços mais baixos. É também mais amigável ao meio ambiente porque produz menos resíduos. O corte a laser é muito mais eficiente no uso do material e ajuda a minimizar o desperdício, preservando assim nosso planeta, já que os métodos de corte tradicionais muitas vezes deixam muitos sobras após cada corte.

Oferecemos serviços OEM e ODM. O corte a laser tem quantidade mínima de 1 peça. Fornecemos cotações dentro de três horas. A produção de amostras requer 1 a 3 dias. A entrega em grandes quantidades pode levar de 7 a 14 dias. Nossa capacidade mensal de produção excede 300 000 peças.

Nosso equipe de engenheiros experientes está sempre disponível e pronta para responder às suas consultas. Eles possuem a expertise e o conhecimento para abordar todas as suas preocupações. Peças personalizadas de alta precisão. Tolerância: +/-0,01 mm, Espaço especial: +/-0,005 mm.

Possuímos certificados ISO9001, ISO14001, ISO45001, ISO13485, aeronáutica AS9100, automotiva IATF16949. Podemos produzir peças mecânicas, peças automotivas, peças eletrônicas, peças aeroespaciais, peças para dispositivos médicos, peças para equipamentos de comunicação, peças para energia nova, peças para produtos de construção e uso doméstico.

Oferecemos uma ampla gama de cortes a laser de produção, incluindo 3 eixos e 4 eixos até 6 eixos. Oferecemos uma variedade de capacidades de processamento que incluem torneamento, fresamento e furação, retificação e EDM, impressão 3D. Trabalhamos com muitos materiais diferentes, como cobre, latão e aço alumínio, inoxidável, plásticos e compósitos.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Todos os direitos reservados — Política de privacidade—Blog