Edifício 49, Parque Industrial Fumin, Vilarejo de Pinghu, Distrito de Longgang

Domingo Fechado

A Swords Precision é uma oficina de máquinas que constrói grandes equipamentos para produzir pequenas peças. Uma operação específica que eles utilizam é chamada de " Peças de precisão aeroespacial . Ela usa máquinas, calor e muita força para transformar metal líquido em sólidos. Fazer peças que podem ser usadas em muitas formas diferentes de maquinário é inteligente e economiza muito dinheiro. Isso é o mais atrativo na fundição por injeção, pois pode gerar esses componentes com velocidade e precisão. Isso significa que, mesmo sendo pequenas, cada peça exige artesanato e calibração.

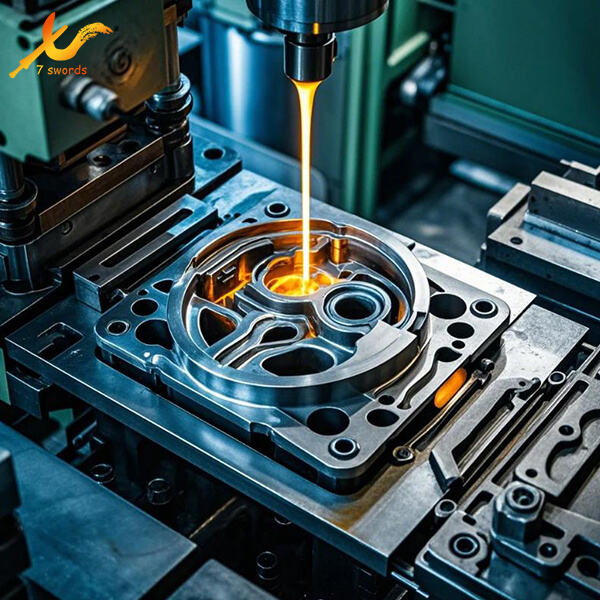

Então, como funciona na verdade a fundição por injeção? Como primeiro passo, você precisa aquecer o metal líquido até que se transforme em uma substância pegajosa e quente. Este passo é crucial; se o metal não for aquecido corretamente, ele não irá preencher o molde. Quando o metal está derretido, ele é levado a uma máquina especial que nos ajuda a despejar o líquido em um molde. Um molde é um design personalizado feito especificamente para a peça que deve ser produzida. O metal líquido quente enche o molde, depois esfria, solidificando-se na cavidade. Quando não estiver mais no estado líquido, a máquina se abre e você pode retirar a forma sólida. Parece simples, certo; mas há vários passos que devem ser seguidos para tudo ocorrer da melhor maneira possível. Você precisa ter certeza de que cada etapa foi cumprida para garantir um produto final desejável.

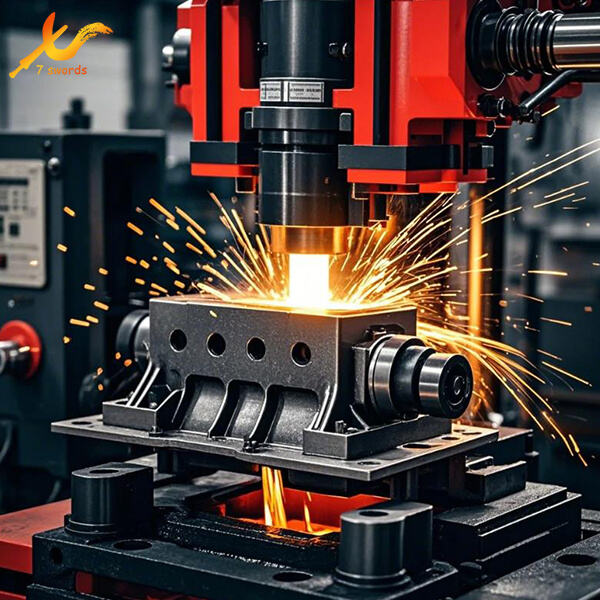

Existem várias maneiras de fazer Peças CNC de Alumínio , dependendo do tipo de peça que precisa ser fundida. Uma maneira é o que se refere como fundição por câmara quente. Neste método, a máquina ainda contém um vaso cheio de metal líquido, mas compare isso com ter uma tigela quente de sopa (enquanto o gosto suave apenas toca). Como o metal já está na máquina, as peças podem ser feitas instantaneamente sem precisar recarregar o metal cada vez que uma nova peça é criada. Isso permite que o processo seja realizado rapidamente e suavemente.

Outro processo é conhecido como fundição por câmara fria. O metal líquido é mantido fora da máquina neste método. Quando uma peça precisa ser criada, o metal é colocado na máquina. Melhor para metais que não devem ser aquecidos demais. Esses métodos têm suas próprias vantagens, e a Swords Precision sabe qual tipo de método deve ser usado para cada tipo de peça para garantir que ela fique correta.

A escolha do metal para fundição por injeção é altamente crítica. Esses metais são mais fortes e adequados para componentes que precisam ser algo como os utilizados em carros ou aviões. Metais mais leves são ideais para componentes que não devem ser mais pesados do que o necessário (por exemplo, brinquedos, dispositivos eletrônicos). Nossos especialistas na Swords Precision podem ajudá-lo a escolher o melhor metal para suas necessidades. Os metais incluem alumínio, magnésio e zinco, todos usados em diversas aplicações para fabricar componentes mais fortes e leves.

Assim como muitas outras tecnologias, a fundição por injeção não é estática, mas continua evoluindo. A Swords Precision sempre está atualizada com as últimas tendências para fornecer a vocês as melhores peças disponíveis. Entre elas, os conceitos mais recentes envolvem o uso de robôs para auxiliar na fundição por injeção. Robôs podem realizar tarefas incrivelmente rápido, tornando o processo ainda mais preciso! A produção dessas peças pode ser mais rápida e de melhor qualidade.

Uma ramificação da tendência é chamada de "verde" fundição por injeção. Isso indica que as máquinas são feitas para consumir menos energia e gerar menos poluição. Isso não só é benéfico para o ambiente, como também economiza custos para a organização. A Swords Precision está constantemente buscando maneiras de inovar e melhorar seus processos. Eles querem fazer sua parte e fornecer as melhores peças possíveis por tanto tempo quanto possível.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Todos os direitos reservados — Política de privacidade—Blog