Revolutionizing Manufacturing with “Custom Plastic Parts Machining”: The Future of Precision and Innovation

In today’s fast-paced manufacturing landscape, custom plastic parts machining.

has emerged as a game-changer, offering industries the precision, versatility, and efficiency they need to stay competitive. As demand for specialized plastic components continues to rise, the ability to create high-quality, tailor-made parts with precision has never been more critical. Custom plastic parts machining.

is no longer a luxury—it's a necessity for businesses seeking to innovate, reduce costs, and speed up production timelines.

From the medical field to automotive engineering, custom plastic parts are increasingly being used across various sectors. This growing trend can be attributed to several factors, including the increasing need for lightweight components, cost-effective production, and the ability to customize designs for unique applications.

What is Custom Plastic Parts Machining?

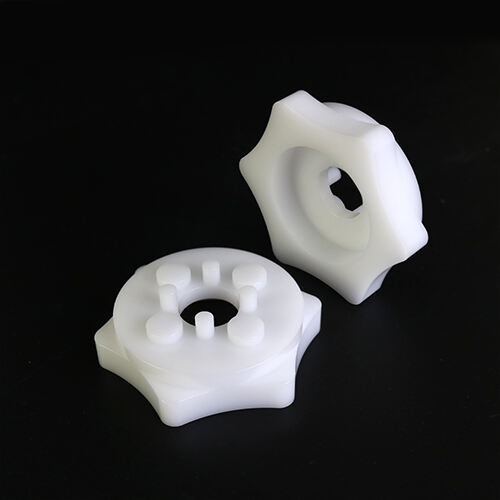

Custom plastic parts machining is a manufacturing process.

where plastic materials are cut, shaped, or molded into specific, high-precision parts according to a customer's design specifications. Using advanced techniques such as CNC milling turning, drilling, and laser cutting, manufacturers can produce a wide range of plastic components that meet exacting standards for quality, size, and functionality.

These plastic parts are typically used in industries that require specific material properties, such as durability, chemical resistance, or electrical insulation. From small-scale production to high-volume runs, custom plastic machining enables manufacturers to create parts with intricate details and tight tolerances, making it an indispensable tool for modern production processes.

Why Custom Plastic Parts Machining is Gaining Popularity

Several factors have contributed to the increasing demand for custom plastic parts machining, particularly in high-tech industries that require precision, reliability, and cost efficiency.

Material Versatility: Custom plastic parts can be machined from a wide variety of materials, including acrylic, polycarbonate, nylon, Delrin, ABS, and PTFE. These materials are lightweight, durable, and offer excellent chemical and wear resistance, making them ideal for a range of applications—from medical devices to consumer electronics.

Cost-Effective for Low and Medium Production Runs: Unlike traditional injection molding or die casting, custom plastic parts machining does not require expensive molds or tooling. This makes it an affordable solution for low to medium production runs, where tooling costs might otherwise be prohibitive.

Precision and Tight Tolerances: CNC machining can produce plastic parts with tight tolerances (as precise as ±0.001 inches), ensuring that components fit together seamlessly and perform reliably. This level of precision is particularly important for industries like medical device manufacturing, where even the smallest deviations can have significant consequences.

Complex Geometries and Customization: With custom plastic machining, manufacturers can easily produce complex shapes, multi-dimensional features, and highly customized components. Whether it’s creating intricate grooves, threads, or custom shapes, CNC machines allow for the flexibility needed to meet demanding design requirements.

Rapid Prototyping: One of the standout features of custom plastic machining is the ability to quickly produce prototypes. This is invaluable for designers and engineers who need to test and refine their designs before moving to mass production. Rapid prototyping reduces development time, accelerates time-to-market, and minimizes costly errors.

Key Benefits of Custom Plastic Parts Machining

Increased Efficiency: Custom plastic machining is faster and more efficient than traditional manufacturing methods, particularly when it comes to small and medium batch sizes. The automation of CNC machines allows for quick turnarounds and consistent results, leading to improved production timelines.

Improved Material Properties: Unlike traditional molding methods, machining offers the flexibility to use a wide range of plastic materials with specific properties suited to different applications. Whether it’s flame-retardant plastics for electronics or biocompatible materials for medical devices, custom machining can accommodate various needs.

Reduced Waste: Since custom plastic machining is a subtractive process, it minimizes material waste by using only the necessary material for each part. This efficiency makes the process more sustainable compared to methods like injection molding, which can produce significant scrap.

Superior Surface Finish: CNC machines can provide parts with high-quality surface finishes, which are often critical for aesthetic and functional purposes. This is especially important in industries like automotive and consumer products, where the appearance of the part is just as important as its performance.

Industries Benefiting from Custom Plastic Parts Machining

Medical Devices: Precision is critical in medical device manufacturing, and custom plastic parts are often used in components such as surgical tools, implants, and patient monitoring devices. Plastics like polycarbonate and POM (Delrin) are commonly machined for these applications because of their strength, clarity, and biocompatibility.

Automotive: The automotive industry has long relied on plastic components for their lightweight, cost-effective nature. From dashboard panels and interior components to under-the-hood parts, custom plastic machining allows for the production of high-performance parts that meet strict regulatory standards.

Electronics: In the electronics sector, custom plastic machining is used to produce enclosures, connectors, and circuit board mounts. Plastic parts are crucial for protecting sensitive electronics from environmental factors, while also providing insulation and durability.

Aerospace: The aerospace industry demands parts that are both lightweight and strong, which is why materials like PEEK and PTFE are commonly used. CNC machining allows aerospace manufacturers to produce high-precision components for engines, landing gear, and cabin interior parts.

Consumer Goods: Custom plastic parts are also used in a variety of consumer products, including appliances, toys, kitchen tools, and sporting goods. CNC machining enables businesses to quickly iterate on designs and bring innovative products to market faster.

How Does Custom Plastic Parts Machining Work?

Design: The process begins with the creation of a detailed design, usually through CAD (Computer-Aided Design) software. This step outlines the part’s dimensions, features, and material specifications.

Material Selection: Based on the application requirements, the appropriate plastic material is selected. For example, high-strength plastics like Nylon might be chosen for mechanical parts, while Polycarbonate may be selected for parts requiring transparency.

CNC Machining: The raw plastic material is fed into a CNC machine, where it is shaped, drilled, cut, and finished according to the design specifications. The machine is programmed with G-code, which dictates the cutting tool’s movements, ensuring precision and consistency throughout the process.

Post-Processing: After the part is machined, it may undergo additional post-processing steps such as deburring, polishing, or surface finishing to meet aesthetic or functional requirements.

Inspection: The final part is thoroughly inspected using tools like CMM (Coordinate Measuring Machines) to ensure that it meets the required tolerances and specifications.

Future Trends in Custom Plastic Parts Machining

As the manufacturing industry continues to evolve, custom plastic parts machining is poised to grow even further. Here are some key trends shaping its future:

Advancements in Materials: The development of high-performance plastics like PEEK, ULTEM, and PTFE is enabling even more demanding applications, particularly in the aerospace, automotive, and medical sectors.

Sustainability: With increasing attention on environmental impact, companies are focusing on recycling plastic materials and reducing waste in the machining process. Sustainable materials like bioplastics may become more prevalent in the coming years.

Automation and AI: The integration of artificial intelligence (AI) and machine learning into CNC machining will improve production efficiency, reduce errors, and further enhance precision.

3D Printing Integration: The combination of 3D printing with traditional CNC machining is creating hybrid processes that can reduce production times and provide additional design flexibility.