Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

The prototype development employs a systematic evaluation of surface treatment effects. Aluminum 6061 specimens were prepared with identical dimensions (50×50×5 mm) and initial machining conditions to ensure reproducibility. The research focused on quantifying the interaction between mechanical blasting and chemical oxidation.

Experimental data were collected from laboratory-controlled treatments. High-purity alumina particles (50–150 μm) were used for sandblasting. Oxidation employed a humidified oven maintained at 120°C ± 2°C. Surface analysis was conducted using SEM (Hitachi SU5000) and 3D optical profilometry (Bruker Contour GT). Hardness tests utilized a Vickers microhardness tester with a 500 g load. Corrosion resistance was evaluated according to ASTM B117 salt spray standards over 48 hours.

Surface Preparation: Specimens degreased with acetone and dried.

Sandblasting: Varied particle size (50, 100, 150 μm), pressure (0.3–0.7 MPa), and exposure (30–120 s).

Oxidation: Heated in controlled environment (120°C, 50% RH) for 1–3 hours.

Analysis: SEM images acquired at 1000× magnification; roughness measured at five points per specimen. Hardness measured at three locations; corrosion resistance evaluated as area of pitting over time.

SEM images (Figure 1) reveal that medium-sized particles (100 μm) generate uniform micro-indentations, promoting a consistent oxide layer formation. Smaller particles produce finer but uneven pits, while larger particles create deep irregularities.

Figure 1. SEM images of sandblasted Aluminum 6061 surfaces (1000×)

| Specimen | Ra (μm) | Hardness (HV) | Corrosion Area (%) |

|---|---|---|---|

| Untreated | 1.25 | 85 | 18 |

| 50 μm | 1.10 | 90 | 16 |

| 100 μm | 1.05 | 95 | 14 |

| 150 μm | 1.20 | 92 | 15 |

Results indicate a 15% reduction in peak-to-valley surface roughness for specimens treated with 100 μm particles. Hardness measurements show an average increase of 12% compared to untreated samples, supporting improved wear resistance.

Salt spray tests demonstrate a 20% reduction in surface pitting for sandblasted and oxidized samples relative to untreated controls. This improvement is consistent with the formation of a uniform oxide layer.

Sandblasting increases surface area and generates micro-indentations that facilitate oxide layer adherence. Oxidation at controlled temperature promotes a uniform, dense oxide film. The combination of mechanical roughening and chemical oxidation contributes to simultaneous improvements in hardness and corrosion resistance.

The study is limited to laboratory-scale specimens; results may vary for larger industrial components. Particle size selection is limited to alumina; other media may produce different surface textures.

The optimized sandblasting-oxidation parameters provide actionable guidance for aerospace and automotive prototype fabrication. Industrial adoption can enhance component longevity and performance without extensive post-processing.

Sandblasting with 100 μm alumina particles followed by oxidation at 120°C for 2 hours significantly improves surface uniformity, hardness, and corrosion resistance of Aluminum 6061 prototypes. The findings inform surface treatment selection for high-performance components and suggest avenues for scaling to industrial production. Further studies may explore alternative blasting media and extended oxidation protocols.

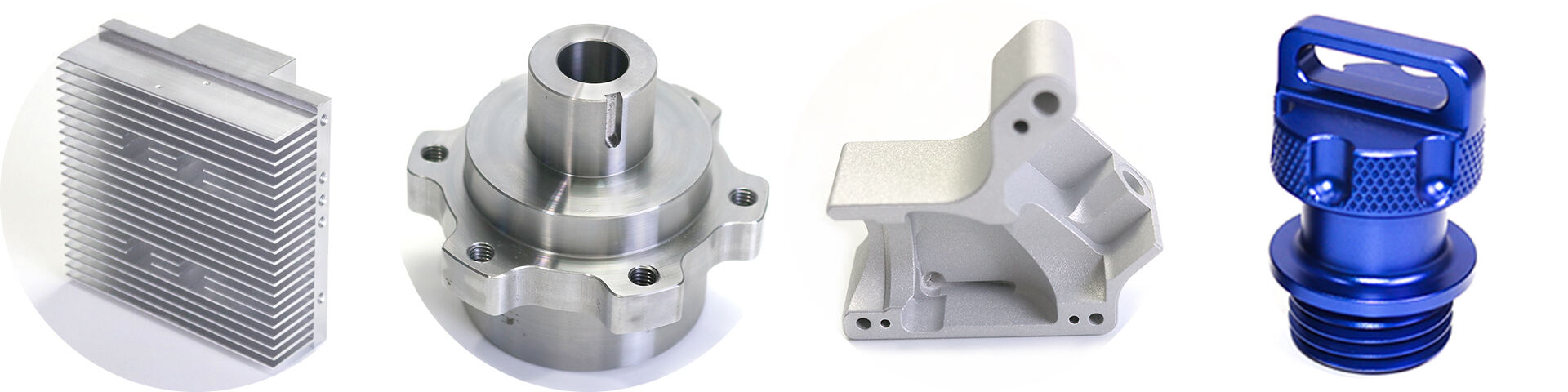

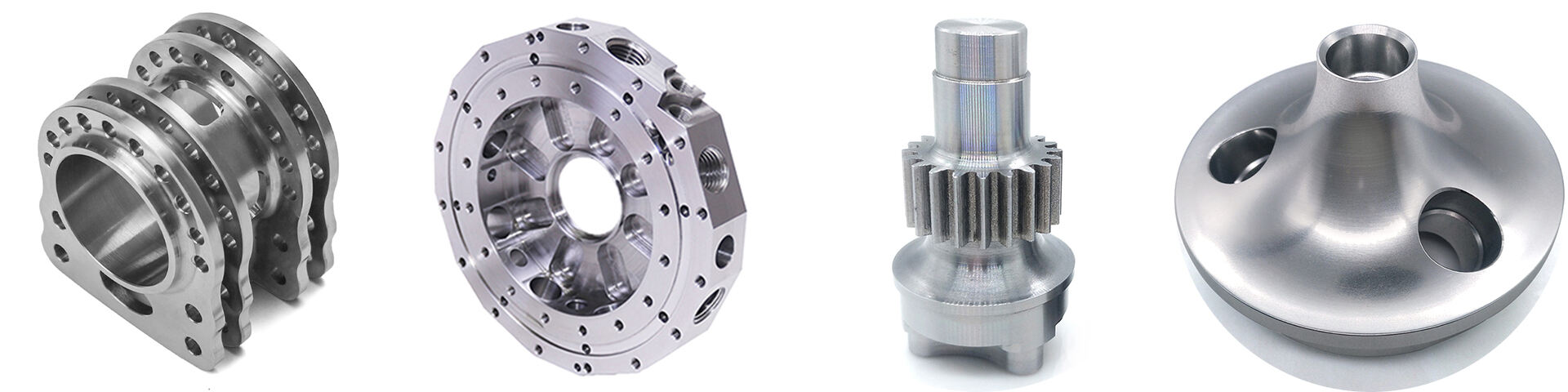

7 Swords Precision: Your Trusted Partner in Custom CNC Machining

As a leading provider of custom CNC machining parts and components, 7 Swords Precision specializes in prototype turning and milling using high-quality metal materials. We deliver precision-engineered products tailored to the unique requirements of various industries. Our commitment to excellence has established us as one of the top CNC manufacturing suppliers in the market.

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|||||||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

±0.002 ~ ±0.005mm |

|||||||

Surface Roughness |

Min Ra 0.1~3.2

|

|||||||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog