CNC machining is really important thing in factories for making products. It help create lots of stuff we using everyday. But sometimes errors happening during this process. At Swords Precision, we think its very crucial to know these common mistakes and ways to avoid it.

Introduction

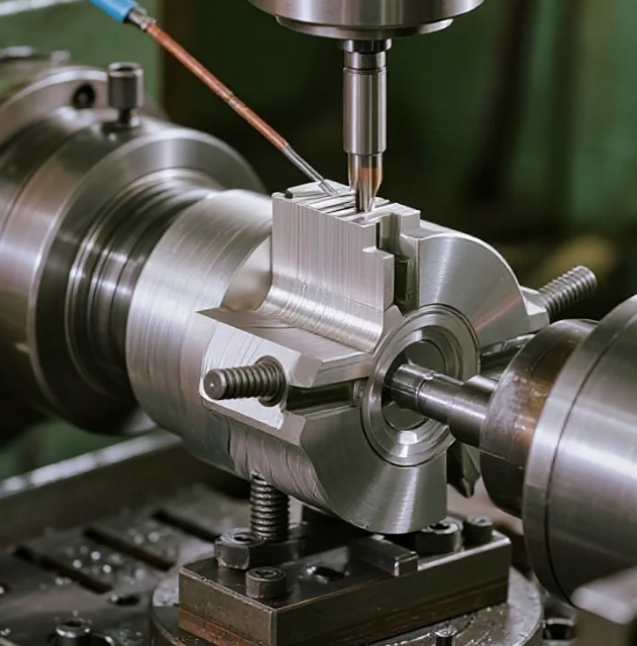

One usual mistake in wholesale production is puting wrong tool parameters. When the programmer put incorrect number for speed or feed rate, it cause bad cuts and waste material. For example if tool spin too fast, it overheat and can break easy. This not only cost money but also make delay in production. And another mistake is using wrong type material for the job. Every material have own needs for machining, choosing wrong one lead to defects. Like if you try cut aluminum with tool for steel, product can get ruined. Also not maintaining properly the CNC machine cause many issues.

Benefits

Finding and fixing CNC machining errors is important before it become costly. One way to spot mistake is watch machine closely when its working. For example listen for weird noise or see vibrations that not normal. These signs usually mean something wrong. Also using test piece before full production run can catch error early. If test piece not good, you can adjust without wasting too much material. Another good practice is check machine software settings regular. Sometime updates change how machine operate.

What Wholesale Buyers Need to Know About CNC Machining Quality Control

When talk about CNC plastic parts quality control is super important. CNC machines, that mean Computer Numerical Control machines, help make parts for many products. These machines use computer program to cut and shape materials like metal or plastic. Because parts often used in big things like car or electronic, any mistake can cause big problem. So how we make sure everything done right? First, wholesale buyers need understand what quality control mean in CNC machining.

How to Choose Right CNC Machining Partner to Remove Mistakes

Choosing good CNC machining partner is crucial to avoid mistake in production. When wholesale buyers search for CNC milling parts they should keep few things in mind. First, check company experience. Company like Swords Precision who in business long time usually know handle different project well. Experience help understand common problem and fix quick. Next, look at type of machines company use. Advanced machine can make better and more precise part. Good partner will have range of modern equipment for different material and design. Also important ask about quality control process. As said before, good quality control catch mistake before become big problem. Buyers need make sure partner do regular inspection and test to guarantee parts meet standard.

CNC Machining Errors Usually Happen in Wholesale Manufacturing

CNC machining errors can happen in several place during manufacturing. Knowing where mistake often occur can help buyers prevent it. One common area is during design phase. If design file sent to machine have error or not clear, it lead to bad parts produced. Thats why essential double-check all design before send to manufacturer. At SCNC machining parts we always recommend client review design careful. Another place error happen is machine setup. If machine not set correct or tool is worn, parts cut not accurate. This why regular maintenance and careful setup very vital. Operators also must be well trained to use machine proper. Mistake also can happen in material selection.