Tòa nhà 49, Khu công nghiệp Fumin, thôn Pinghu, quận Longgang

Chủ nhật Nghỉ

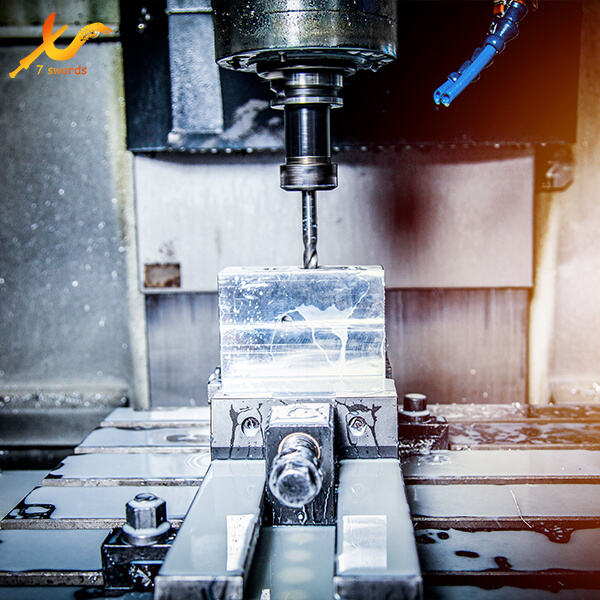

Một linh kiện kim loại CNC là một yếu tố độc đáo được sản xuất từ công nghệ Điều khiển Số bằng Máy tính (CNC), tương tự như sản phẩm của Swords Precision như Bộ phận chính xác hàng không vũ trụ . Cơ bản đây là những thứ được sản xuất, thay vì bởi con người, một máy tính sẽ chỉ đạo máy móc phải làm gì. Đây là lý do khiến máy CNC cực kỳ chi tiết và phù hợp cho nhiều công việc/ngành nghề.

Những bộ phận này có thể đạt gần như hình dạng hoàn hảo nhất mà máy CNC có thể sản xuất. Chúng làm được điều này bằng cách đọc chính xác lệnh từ máy tính và xây dựng chúng với độ chính xác cao. Điều này rất quan trọng vì nó khiến các bộ phận trở nên linh hoạt hơn, điều này sau đó cho phép chúng hữu ích trong nhiều ứng dụng khác nhau. Độ chính xác của thanh kiếm đảm bảo rằng tất cả các bộ phận còn lại đều được sản xuất theo các tiêu chuẩn cực kỳ khắt khe về độ dung sai, sự vừa khít và bề mặt hoàn thiện bởi các kỹ thuật viên CNC từ vị trí của thanh kiếm. Nói một cách đơn giản, các sản phẩm họ phát triển là đáng tin cậy và có thể áp dụng vào nhiều loại sản phẩm khác nhau.

Phạm vi của công nghệ CNC đã ảnh hưởng lớn trong lĩnh vực sản xuất, tương tự như Các công ty gia công CNC được sản xuất bởi Swords Precision. Điều này cho phép sản xuất các bộ phận kim loại, loại bỏ việc phỏng đoán mò và tiết kiệm hàng giờ lao động thủ công. Hầu hết chúng ta hiện nay có thể sản xuất các bộ phận kim loại rất chính xác và có thể lặp lại được nhờ vào các máy CNC. Sự cải tiến này cho phép chúng ta xây dựng sản phẩm nhanh hơn và với chi phí thấp hơn so với trước đây. Dù có thể công nghệ này là của tương lai, nhưng nó sẽ tồn tại lâu dài, giúp dịch vụ của chúng ta tốt hơn và cuối cùng trở thành lựa chọn hàng đầu cho các bộ phận cần độ chính xác cao.

Lợi thế chính mà chúng ta đã thu được từ việc sử dụng công nghệ CNC là nó cho phép chúng ta tạo ra các bộ phận kim loại bằng cách điều chỉnh theo thiết kế, cũng như sản phẩm của Swords Precision như Các bộ phận máy CNC . Nói đơn giản hơn, thay vì sản xuất hàng loạt một bộ phận tiêu chuẩn, chúng ta có thể sử dụng dữ liệu để thiết kế và chế tạo các bộ phận được làm riêng theo nhu cầu hay tình huống của từng người tiêu dùng. Với mỗi khách hàng, đội ngũ làm việc nhằm hiểu rõ nhu cầu của họ và tạo ra các bộ phận kim loại CNC cá nhân hóa dành riêng cho cá nhân hay doanh nghiệp đó. Không chỉ mang tính cá nhân hóa, cách này còn đảm bảo khách hàng nhận được đúng những gì họ cần để thực hiện công việc của mình.

CNC là công nghệ cho phép cung cấp dịch vụ tạo nguyên mẫu nhanh chóng, điều này rất quan trọng đối với nhu cầu của ngành công nghiệp, cùng với Phụ tùng gia công CNC . Ví dụ, ngành hàng không hay máy bay sẽ yêu cầu một số bộ phận kim loại phải được chuyển đổi thành các bộ phận có độ bền và khả năng chống chịu cao, tương tự như trang thiết bị y tế được sử dụng trong chăm sóc sức khỏe bởi ngành Y tế. Đây cũng chính là lý do công nghệ CNC cho phép sản xuất các bộ phận kim loại với độ chính xác và sự phức tạp phù hợp chặt chẽ với các yêu cầu riêng của từng ngành. Nhờ đó, các công ty sử dụng bộ phận của chúng tôi có thể hoàn toàn tin tưởng vào hiệu suất và độ bền lâu dài của sản phẩm.

Bộ phận kim loại là những bộ phận được gia công CNC hiệu quả nhất, giống như sản phẩm có tên gọi Gia công các bộ phận nhựa theo yêu cầu . Thực tế, với hiệu quả này, chúng tôi có thể tạo ra các bộ phận chính xác và lặp lại được hơn so với cách làm việc cũ. Hơn nữa, máy CNC có thể hoạt động không người điều khiển trong phần lớn thời gian do bản chất là thiết bị tự động hóa. Điều này không chỉ giúp đẩy nhanh quá trình sản xuất từ phía chúng tôi, mà còn tiết kiệm chi phí. Điều này cho phép chúng tôi cung cấp các linh kiện kim loại CNC nhanh chóng và giá rẻ với chất lượng đảm bảo cho khách hàng.

Chúng tôi có chứng nhận ISO9001, ISO14001, ISO45001 các bộ phận kim loại CNC ISO13485, hàng không AS9100, ô tô IATF16949, chúng tôi có thể sản xuất các bộ phận cơ khí, bộ phận ô tô, bộ phận điện tử, bộ phận hàng không vũ trụ, bộ phận thiết bị y tế, bộ phận thiết bị viễn thông, bộ phận năng lượng mới, bộ phận sản phẩm xây dựng và gia dụng.

Chúng tôi cung cấp dịch vụ OEM và ODM cho các bộ phận kim loại CNC. Số lượng đặt hàng tối thiểu là 1 đơn vị. Báo giá được gửi trong vòng ba giờ. Mẫu sản phẩm mất từ 1 đến 3 ngày, trong khi giao hàng số lượng lớn mất từ 7 đến 14 ngày. Năng lực sản xuất hàng tháng của chúng tôi vượt quá 300.000 sản phẩm

Họ có nhiều kinh nghiệm và các bộ phận kim loại CNC để giải đáp tất cả các thắc mắc của bạn. Kiến thức và chuyên môn rộng rãi của họ sẽ giúp bạn giải quyết các vấn đề. Các bộ phận theo yêu cầu độ chính xác cao Dung sai: +/- 0.1 mm, Không gian đặc biệt: +/0.005 mm

Thiết bị sản xuất của chúng tôi bao gồm các bộ phận kim loại CNC (4 trục), máy 5 trục và lên đến 6 trục. Chúng tôi có nhiều tùy chọn gia công như tiện, phay, mài, khoan, cắt bằng tia lửa điện (EDM) và in 3D. Chúng tôi xử lý đa dạng vật liệu như nhôm, đồng thau, đồng, thép, thép không gỉ, nhựa và vật liệu composite để chế tạo các bộ phận có thể đáp ứng mọi nhu cầu công nghiệp.

Bản quyền © Công ty TNHH Sản phẩm Chế tạo Chính xác Perfect Shenzhen. Tất cả các quyền được bảo lưu — Chính sách bảo mật—Blog