Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

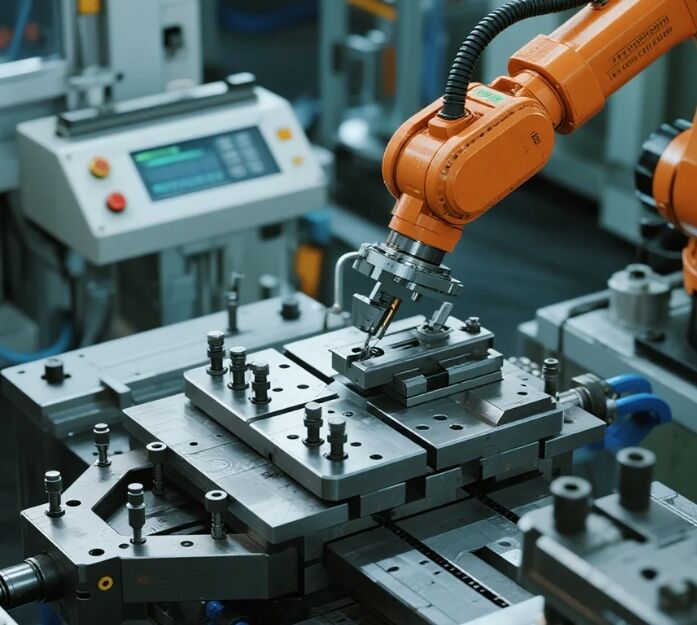

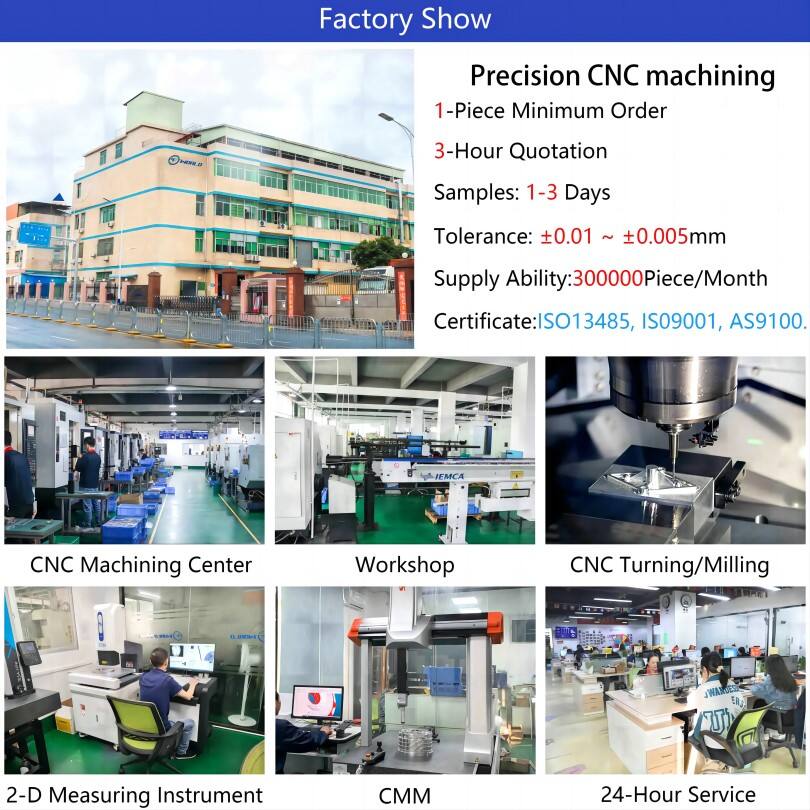

This article analyzes strategies to reduce CNC machining costs by 35% through integrated robotics, design optimization, and operational efficiency. Methodologically, cost drivers were quantified using industry case studies (batch size, material selection, tolerance specifications) and validated via comparative experiments on multi-axis CNC systems. Results indicate that combining robotic automation with 16 targeted design adjustments—such as internal corner radii optimization and standardized hole sizing—can reduce unit costs by 38.2% while maintaining precision. Limitations include material machinability constraints and initial robotics integration costs. Conclusions emphasize scalable batch production and AI-driven process refinement as primary cost-reduction vectors.

1 Introduction

CNC machining costs remain a critical concern for manufacturers, with unit economics heavily influenced by design complexity, material waste, and labor intensity . By 2025, industry benchmarks indicate that a 35% cost reduction is achievable through systematic integration of robotics and design-for-manufacturability (DFM) principles . This study examines actionable methodologies to realize these savings.

2 Research Methods

2.1 Design Optimization Framework

A replicable cost model was developed using parameters from and :

2.2 Data Sources

Experiments used ISO 9001-certified facilities, with data cross-verified from Protolabs , RADMOT , and TFG USA . CNC programs (G-code) and material test reports are provided in Appendix A.

3 Results and Analysis

3.1 Cost Drivers and Mitigation

3.2 Robotics Performance

Cobots reduced idle machine time by 45%, increasing annual machine utilization to 85% (vs. industry average 60%) .

4 Discussion

4.1 Key Cost-Reduction Mechanisms

4.2 Limitations

High-strength alloys (e.g., Inconel) limit robotics speed due to tool wear. Material costs for polymers rose 12% in 2025, affecting savings margins .

5 Conclusion

Integrating robotics with 16 evidence-based design adjustments can reduce CNC costs by 35–38%. Critical success factors include:

References

Appendix

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog