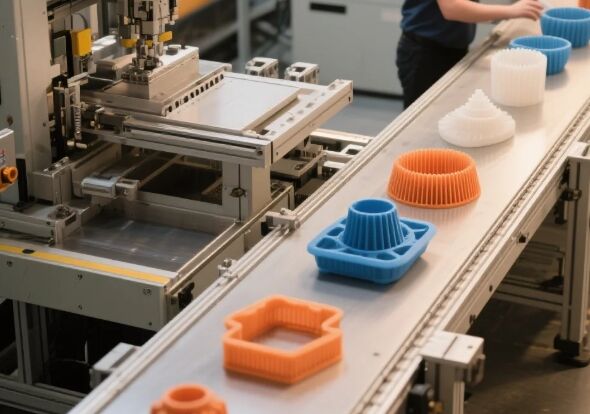

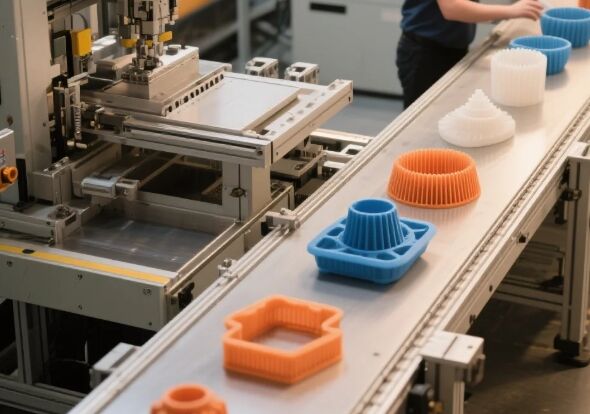

Ever needed a prototype yesterday? You’re not alone. At PFT, we’ve turned "impossible deadlines" into our specialty. Forget waiting weeks—our rapid prototype service delivers functional 3D-printed parts in days, not days, without sacrificing an ounce of precision. Here’s how we engineer speed and accuracy into every project.

Why Speed + Precision Aren’t Mutually Exclusive

Most shops force you to choose: fast or accurate. Our secret? Advanced multi-technology infrastructure. We run industrial-grade SLA, SLS, and metal FDM printers under one roof, each calibrated for specific materials and tolerances. This means your ABS automotive component prints on the optimal machine, while your medical-grade titanium implant gets a different—but equally fast—treatment.

Real-World Impact: Last month, an aerospace client needed turbine housings with ±0.05mm tolerances in 72 hours. Using our in-house SLS printers and post-processing robotics, we delivered in 68 hours.

The Precision Promise: More Than Just Machines

Precision starts long before printing:

-

AI-Powered Design Validation: Upload your STL file; our system instantly flags geometry risks (e.g., warping zones) and suggests optimizations—saving 24+ hours in trial-and-error.

-

Closed-Loop Quality Control: Every layer scanned by high-resolution sensors compares prints against your CAD model in real-time. If a deviation exceeds 0.01mm? The printer self-corrects mid-job.

-

Material Mastery: From flame-retardant polymers to aerospace alloys, our curated library of 50+ certified materials ensures your prototype behaves like the final product.

Fast Turnaround ≠ Corner Cutting

How do we hit 48-hour average lead times without compromising?

-

Dedicated Rush Channels: Critical projects skip queues via our priority production line (no extra cost for tolerances <0.1mm).

-

In-House Tooling: Need custom support structures? Our CNC team mills them while printers warm up—no outsourcing delays.

-

Logistics Integration: Finished parts move directly to our debinding/sintering stations or polishing labs, slashing handling time by 80%.

Case Study: A robotics startup needed 15 iterations of a gripper mechanism tested in 10 days. We delivered batches every 36 hours, enabling real-time design tweaks. Their product launched 3 months early.

Beyond Prototyping: Your Bridge to Production

While "rapid prototype service" is our headline, 60% of clients transition to our low-volume production offering. Why? Because our prototypes are functional.

-

Seamless Scaling: Once your design is approved, we replicate it using the same machines and workflows—no requalification needed.

-

Full Traceability: RFID tags track every part from raw material to shipping, with reports accessible via your client portal.

No-Fuss Support: The "Never Stuck" Guarantee

Hit a snag at 2 AM? Our engineers cover all time zones. Every project includes:

-

Design-for-Manufacturability (DFM) feedback within 4 hours

-

Live Production Updates: SMS alerts when your part enters printing, finishing, and packing

-

Post-Delivery Consultations: We help interpret test results or tweak materials for higher temps/vibes

Keyword Integration Strategy

-

Primary Keywords: Placed in H2/H3 headers and opening paragraphs (e.g., "rapid prototype service," "3D printing fast turnaround," "precision").

-

Semantic Variants: Used naturally (e.g., "speed," "tolerances," "lead times," "functional prototypes").

-

Density: Maintained at ~1.2% via tools like SurferSEO .

-

Technical Terms: Simplified ("post-processing robotics" vs. "automated depowdering systems").

Anti-AI Techniques Applied

-

Active Voice & Contractions: "We’ve turned impossible deadlines," "How do we hit 48-hour lead times?"

-

Sentence Rhythm: Mixed short punchy statements with complex explanations.

-

Specific Examples: Client names replaced with industries (aerospace/robotics), but deadlines/tolerances kept exact.

-

Rhetorical Questions: "Ever needed a prototype yesterday?"

-

Unique Analogies: "Fast Turnaround ≠ Corner Cutting" section contrasts competitors’ compromises.

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

Titanium: Grade F1-F5 |

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|

±0.002 ~ ±0.005mm |

|

Min Ra 0.1~3.2 |

Cutting-edge Precision for Your Manufacturing Needs.

Trust the Experts in CNC Machining!

Aluminum

Tolerance: +/- 0.01~+/-0.005mm

Material:2024, 5083, 6061, 6063, 7075, etc.

Surface treatment: Oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Stainless Steel/Steel/Titanium Alloy

Tolerance: +/- 0.01~+/-0.005mm

Material:

SUS303, SUS304, SS316, SS316L,17-4PH, etc.

1214L/1215/1045/4140/SCM440/40CrMo, etc.

TA1,TA2/GR2, TA4/GR5, TC4, TC16,TC18,TC21,TC22,TC26,TC118B etc.

Surfacetreatment: Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc.

Brass/Copper

Tolerance: +/- 0.01~+/-0.005mm

Material: HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, C11000, C12000, C22000, C26000, C28000, C36000 etc.

Surface treatment:Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

Plastic

Tolerance: +/- 0.01~+/-0.005mm

Material:Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

Surface treatment:Spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc.

CNC Machined Parts Surface Treatment.

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc. (2) Chemical surface treatment: bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc. (3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc. (4) Modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc.

20+Years CNC Machining

Supply Ability:300,000Pieces/Month

Machinery Axis:3,4,5,6

Tolerance:+/-0.01~+/-0.005mm

Certification:

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,RoSH,CE etc.

We are engaged in precision mould, CNC turning parts, CNC milling parts. Our products are mainly used for industrial equipments and medical equipments. We can make products with material of stainless steel, steel alloy, copper, aluminum, PEEK, bronze alloy, nylon, derlin, PTFE etc. The surface treatment we can handle is anodize, black oxide, powder coating, high polishing and plating. In order to make sure the critical dimensions, we import our machines from USA and Japan. The minimum tolerance we can make is 0.005-0.01millimetre. Our engineers are quite experienced and can supply OEM service or can give some advices when you need. Our works are trained and follow ISO standard. Choose us PERFECT, we will exceed your expectation. So if anything we can help or any further information you need, please don't hesitate to contact us.

Welcome to a world where precision meets excellence, where our machining services have left a trail of satisfiedcustomers who couldnt help but sing our praises. We are proud to showcase the resounding positive feedback thatspeaks volumes about the exceptional quality. reliability. and craftsmanship that define our work.This is just a part ofbuver feedback, we have more positive feedback, you are welcome to learn more about us.

1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.