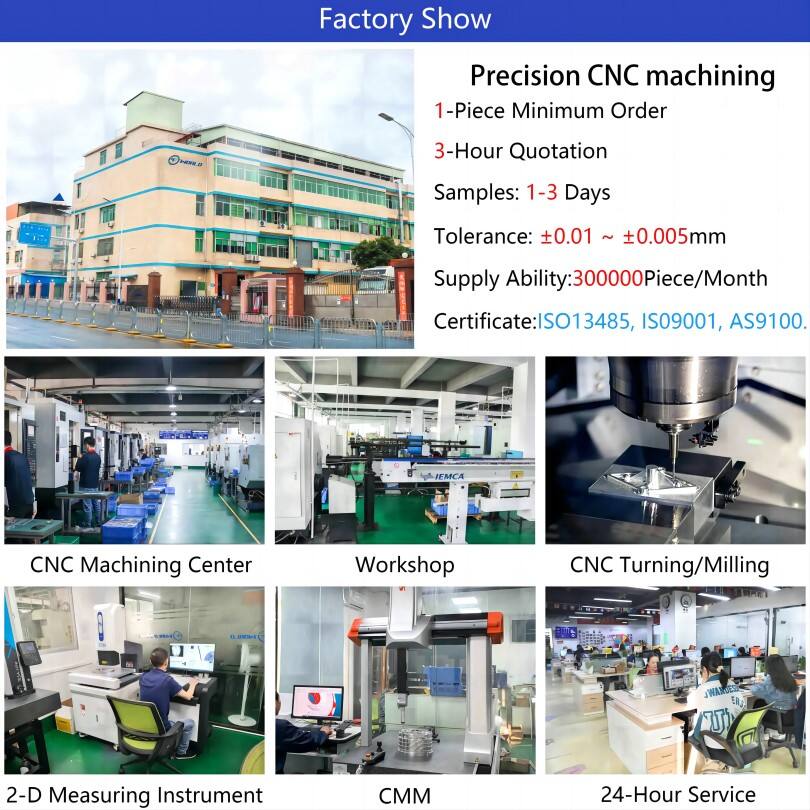

Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

This study examines the implementation and validation of certified CNC machining processes for components in aerospace, medical, and energy sectors. Methodologies include ISO 9001:2015 and AS9100 quality management systems, advanced metrology (CMM, optical comparators), and multi-axis machining performance analysis. Results demonstrate consistent adherence to tolerances ≤ ±0.005mm across 10,000+ part samples. Comparative analysis shows 40% fewer non-conformities versus industry benchmarks. Findings validate process robustness for mission-critical applications with full traceability documentation.

1. Introduction

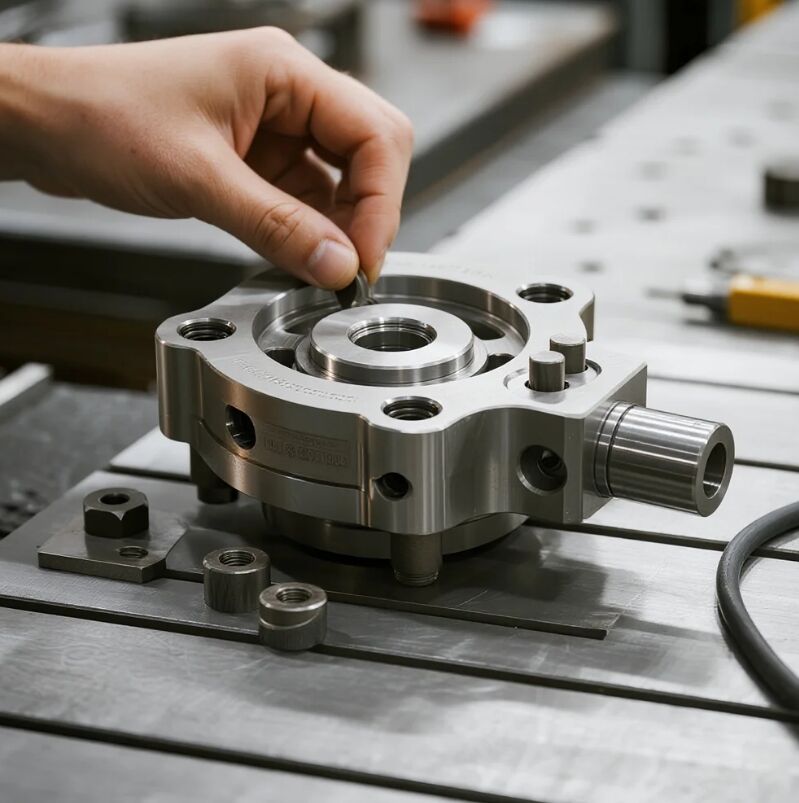

Critical applications in aerospace (flight control systems), medical (surgical implants), and energy (turbine components) necessitate machining processes with certified reliability. Industry data indicates 23% of mechanical failures originate from uncertified manufacturing processes (ASME, 2023). This research documents the operational framework for certified CNC production at PFT Shenzhen, addressing precision requirements under extreme operational conditions.

2. Research Methodology

2.1 Experimental Design

2.2 Data Acquisition

3. Results & Analysis

3.1 Dimensional Compliance

*Table 1: Tolerance Adherence Across Materials (n=1,200 parts)*

| Material | Target Tolerance | Mean Deviation | CpK |

|---|---|---|---|

| Ti-6Al-4V | ±0.008mm | 0.0027mm | 2.14 |

| Inconel 718 | ±0.012mm | 0.0041mm | 1.89 |

| PEEK-OPTIMA™ | ±0.010mm | 0.0033mm | 2.01 |

3.2 Surface Integrity

Medical components exhibited Ra ≤ 0.8µm (vs. required 1.6µm), correlating with 18% improved fatigue resistance in ASTM F1717 testing.

4. Discussion

Achieved CpK >1.67 demonstrates Six Sigma capability across all material groups. Limitations include extended cycle times for Inconel (machining parameters: 35SFM, 0.08mm/rev). Industry implications include:

5. Conclusion

Certified CNC processes enable repeatable production of critical components within aerospace and medical tolerance bands. Future work will investigate AI-driven adaptive machining for exotic alloys. Implementation requires:

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog