Discover how online CNC cutting services streamline procurement, ensure precision, and reduce waste. Learn from real factory experience with Custom Design & Precision Cutting Inc.

The Sound of Precision: A Scene from the Workshop

The sharp hiss of the cutter head. Sparks dancing across a steel sheet. The warm edge of freshly cut metal. That’s the atmosphere of a CNC cutting shop.

As a procurement manager, you may not stand at the machine every day. But you care deeply about what happens here—because the accuracy of each cut directly affects your assembly line performance and customer satisfaction.

What CNC Cutting Really Means

When we say CNC (Computer Numerical Control) cutting, we’re talking about automated cutting guided by programmed instructions. In plain words, it’s like giving GPS coordinates to a robot, and the robot slices material with micrometer accuracy.

For instance, I once needed 200 stainless brackets with tolerances tighter than ±0.1mm. Without CNC cutting (precision-controlled cutting machine), those brackets would have misaligned on the customer’s frame. In procurement, “close enough” doesn’t cut it—literally.

Lessons Learned the Hard Way

Let me be honest—we’ve made mistakes. Once, a CAD drawing (digital blueprint) had a curve radius set incorrectly. We cut through 300 sheets before realizing it. The result? Thousands of dollars in waste and a frustrated customer.

That painful lesson taught us the value of DFM (Design for Manufacturing). This process means reviewing whether a design can be practically manufactured before cutting. Since then, we’ve lived by one golden rule: no review, no run. Isn’t it funny how failure becomes the best teacher?

Why Online CNC Cutting Services Matter

Today, you don’t have to visit a workshop in person. With online CNC cutting services, you simply upload your CAD file, choose material and thickness, and receive a quote in hours.

It feels almost like online shopping—except every “product” is a custom industrial part. Add to that nesting software (which arranges parts on sheets to minimize waste), and you save both time and raw material. And in procurement, every dollar saved on scrap is a dollar earned in margin.

The Value of a Reliable Partner

Whether you’re ordering a single prototype or 10,000 production parts, your cutting partner becomes part of your supply chain stability.

At Custom Design & Precision Cutting Inc, we’ve seen both failures and victories. That’s why our process prioritizes:

- Careful design reviews

- Tight tolerance control

- Transparent feedback loops

- On-time delivery

You expect predictable quality? We deliver it. You value trust? That’s our daily routine. And as your procurement needs grow, remember: the precision we cut today is the reliability you deliver tomorrow.

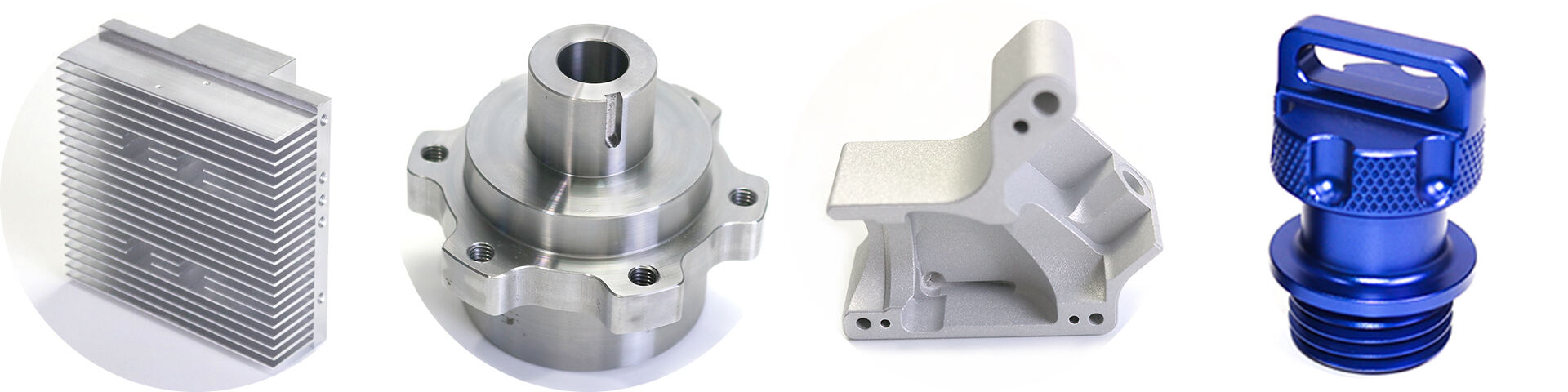

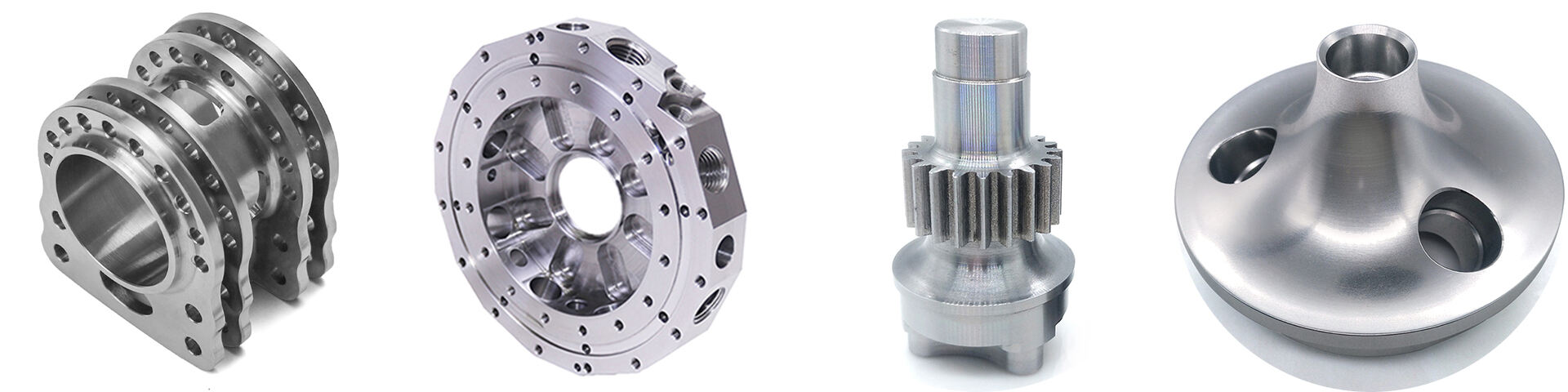

7 Swords Precision: Your Trusted Partner in Custom CNC Machining

As a leading provider of custom CNC machining parts and components, 7 Swords Precision specializes in prototype turning and milling using high-quality metal materials. We deliver precision-engineered products tailored to the unique requirements of various industries. Our commitment to excellence has established us as one of the top CNC manufacturing suppliers in the market.

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including metals, plastics, and composites

Machinery Axis: 3,4,5,6

Tolerance:+/- 0.01mm

Special Areas :+/-0.005mm

Surface Roughness: Ra0.1~3.2

Supply Ability:300000Piece/Month

OEM&ODMCustomized Precision Parts

1-Piece minimum order

3-Hour quotation

Samples: 1-3Days

Lead time:

7-14 Days

QC team, inspectionReport Guarantee:

Lifetime After-Sales Service Certificate:Medical, Aviation, Automobile

ISO13485, IS09001, AS9100, IATF16949

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy

1. ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2. ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3. IATF16949, As9100, SGS2, CE, CQC, ROHS

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|

|

|

|

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|

|

|

|

|

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

|

|

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

|

|

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

|

|

|

|

Titanium: Grade F1-F5 |

|

|

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

|

|

|

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|

|

|

|

|

±0.002 ~ ±0.005mm |

|

|

|

|

|

Min Ra 0.1~3.2

|

|

|

|

|

Cutting-edge Precision for Your Manufacturing Needs

Trust the Experts in CNC Machining

Aluminum

Tolerance: +/- 0.01~+/-0.005mm

Material:2024, 5083, 6061, 6063, 7075, etc

Surface treatment: Oxidation, electro-phoresis, sand blasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc

Stainless Steel/Steel/Titanium Alloy

Tolerance: +/- 0.01~+/-0.005mm

Material:

SUS303, SUS304, SS316, SS316L,17-4PH, etc

1214L/1215/1045/4140/SCM440/40CrMo, etc

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B etc

Surfacetreatment: Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling, shot peening, etc

Brass/Copper

Tolerance: +/- 0.01~+/-0.005mm

Material: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, C11000, C12000, C22000, C26000, C28000, C36000 etc

Surface treatment:Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment, pickling, shot peening, etc

Plastic

Tolerance: +/- 0.01~+/-0.005mm

Material:Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc

Surface treatment:Spraying, sand blasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc

CNC Machined Parts Surface Treatment.

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc (2) Chemical surface treatment: bluish blackening, Phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc (3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc (4) Modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc

20+Years CNC Machining

Supply Ability:300,000Pieces/Month

Machinery Axis:3,4,5,6

Tolerance:+/-0.01~+/-0.005mm

Certification:

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,RoSH,CE etc.

1. Are you a manufacturer or a trading companyWe are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports

2. How to get a quote

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information

3. Can I get a quotation without drawings

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation

4. Can you provide samples before mass production

Of course, the sample fee is necessary. If possible, it will be returned during mass production

5. What is the delivery date

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks

6. How do you control quality

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week