Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

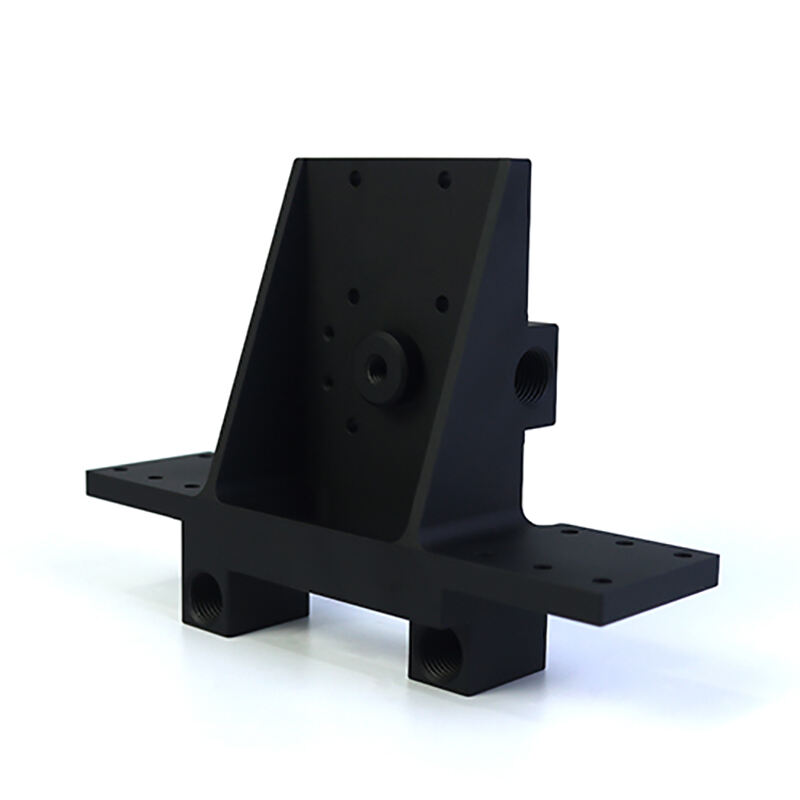

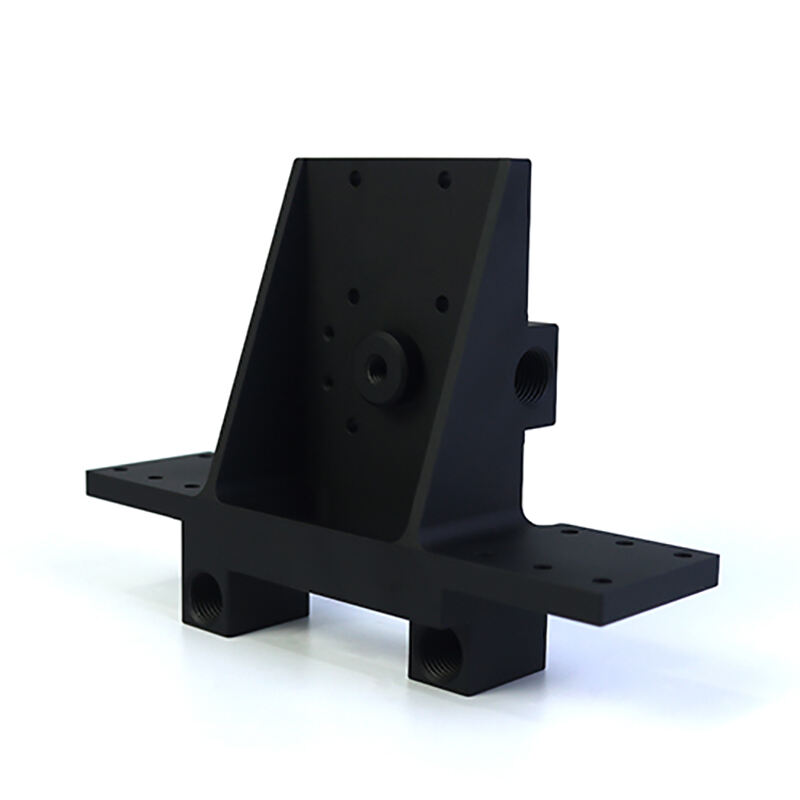

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

Hey there! Ever stare out an airplane window at 30,000 feet and marvel at the engineering? I do. And one question that often pops into my head is: "How do they make parts this reliable?" The answer, more often than not, involves a process called CNC Machining.

In the aerospace sector, there's zero room for error. You can't just pull over if something feels loose. That's why this industry relies so heavily on CNC (Computer Numerical Control) machining. It’s the secret sauce for building the safe, efficient, and powerful aircraft we all depend on. Let's break down why.

In everyday manufacturing, being a millimeter off might be no big deal. In aerospace? It's a complete no-go. We're talking about tolerances within the width of a human hair or even less.

CNC machines are digital ninjas. They follow computer-aided designs (CAD) with insane accuracy, cutting metal blocks into complex components like turbine blades, landing gear parts, and brackets. This repeatable precision ensures that every single part, from the first to the thousandth, is identical and perfect. This is non-negotiable for safety and performance.

Aerospace parts face extreme conditions: crazy heat, intense pressure, and brutal forces. You can't use just any material. That’s why they work with "exotic" stuff like titanium, Inconel, and high-strength aluminum alloys.

The catch? These materials are notoriously tough to work with. They’re hard, they get hot, and they can wear down tools fast. CNC machines, especially modern ones with advanced cooling systems and super-hard tooling, are built for this exact challenge. They can strategically and consistently shape these super-alloys into the resilient parts needed to survive the harsh environment of flight.

Think about an engine component or a fuel system part. They’re not simple cubes; they’re intricate 3D puzzles with internal channels, complex curves, and thin walls.

This is where CNC machining truly shines. Using multi-axis machines (think 5-axis or more), machinists can produce these incredibly complex geometries in a single setup. This eliminates errors that can come from moving a part between different machines and allows for designs that would be impossible with manual machining.

In aerospace, weight is money. The heavier the plane, the more fuel it burns. More fuel means higher costs and more emissions. CNC machining is a key player in "lightweighting."

The process allows engineers to design parts with intricate, weight-saving lattices and pockets, removing every possible speck of non-essential material without sacrificing strength. It’s like carving a sculpture out of metal to leave only the absolute necessary structure behind. This relentless pursuit of lightness is crucial for building the next generation of fuel-efficient aircraft.

CNC machining isn't standing still. It's getting smarter. We're now seeing a seamless "digital thread" where a part is designed, simulated, and its machining instructions are generated all within a connected digital system. This means even fewer errors and faster production.

Plus, a cool new trend is the marriage of CNC with 3D printing (Additive Manufacturing). Parts are often 3D printed in a near-net shape and then brought to their final, flawless dimensions with a CNC finish. It’s the best of both worlds!

So, the next time you’re buckling in for a flight, remember the unseen hero. Those powerful engines and the sturdy airframe are filled with components born from CNC machining. It’s the technology that turns raw, tough materials into the safe, reliable, and high-flying marvels of modern engineering.

Q: How fast can I receive a CNC prototype?

A: Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q: What design files do I need to provide?

A: To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q: Can you handle tight tolerances?

A: Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q: Is CNC prototyping suitable for functional testing?

A: Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q: Do you offer low-volume production in addition to prototypes?

A: Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q: Is my design confidential?

A: Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog