Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

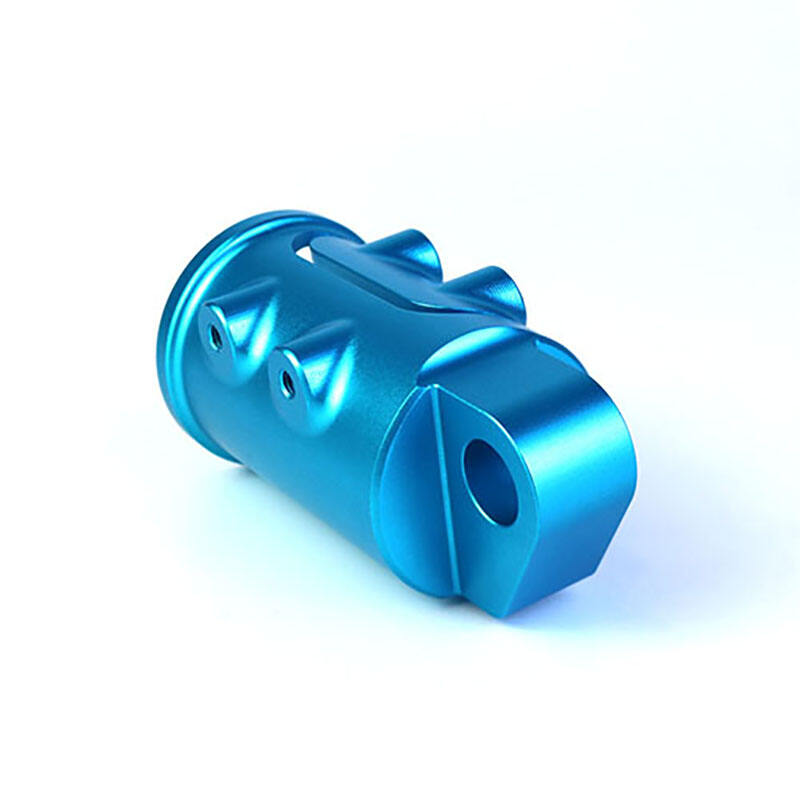

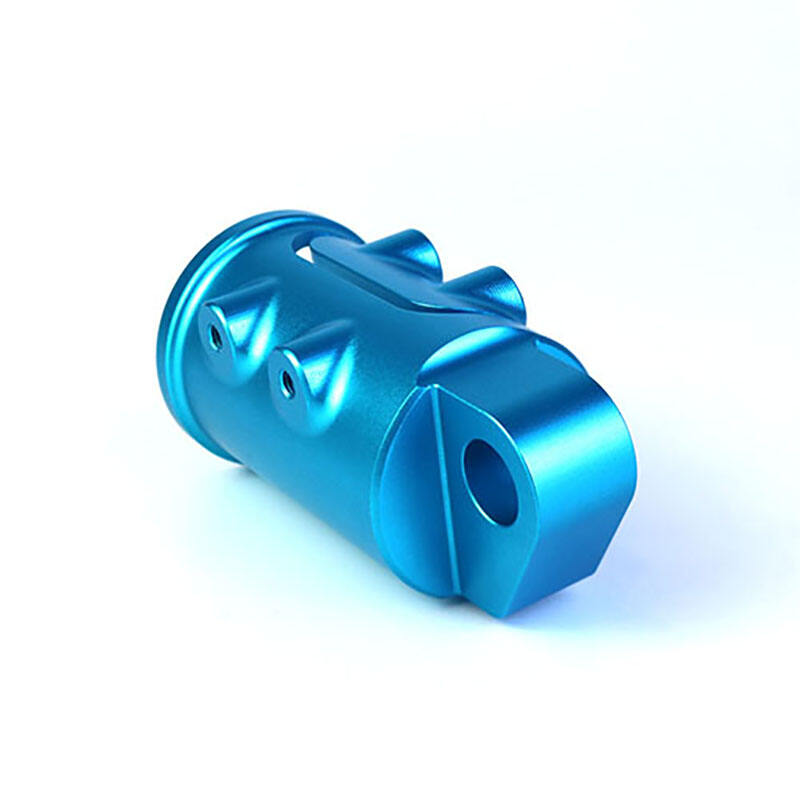

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In today’s fast-moving manufacturing world, precision and durability matter more than ever. Whether you're building aerospace components or consumer electronics, you want parts that not only fit perfectly, but also last. That’s where CNC machining combined with surface finishes like anodizing and plating really shine.

Let’s start with the basics. CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software controls the movement of machinery and tools. It’s a game-changer for making complex parts with tight tolerances, consistently and efficiently. CNC machines can cut, mill, drill, and turn raw materials—usually metals or plastics—into finished parts that are ready to use.

Anodizing is an electrochemical process mainly used on aluminum parts. It thickens the natural oxide layer on the surface, making the part more resistant to wear and corrosion. Plus, anodized parts can be dyed in a wide range of colors—perfect for branding or just making your parts stand out.

• Corrosion resistance

• Improved durability and hardness

• Aesthetic customization (colors)

• Lightweight protection without adding bulk

Plating involves coating a part—usually metal—with a thin layer of another metal. This can be done for aesthetic reasons, but more often it’s about function. For example, nickel plating can make parts more resistant to corrosion and wear. Gold or silver plating can enhance electrical conductivity, which is crucial in electronics.

• Nickel plating: Great for corrosion resistance

• Zinc plating: Budget-friendly rust protection

• Gold/silver plating: Ideal for electrical applications

• Chrome plating: Adds a shiny, durable finish

Here’s the real advantage: by combining CNC machining with custom anodizing超链接:(https://www.7-swords.com/) or plating, manufacturers get the best of both worlds. You get highly precise parts and the exact surface properties you need for performance, longevity, or appearance.

• CNC aluminum brackets can be Type III hard anodized for industrial use.

• Steel shafts can be machined and then chrome plated for smooth movement in mechanical systems.

• Copper components can be CNC machined and silver plated for excellent conductivity in electronics.

This combination is essential in industries like aerospace, automotive, medical devices, robotics, and consumer electronics.

CNC machining is already a powerhouse for making precision parts. But when you add anodizing or plating, you unlock a new level of performance, protection, and professionalism. Whether you’re prototyping or running full-scale production, it's worth considering how these finishing options can elevate your parts—and your final product.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog