Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

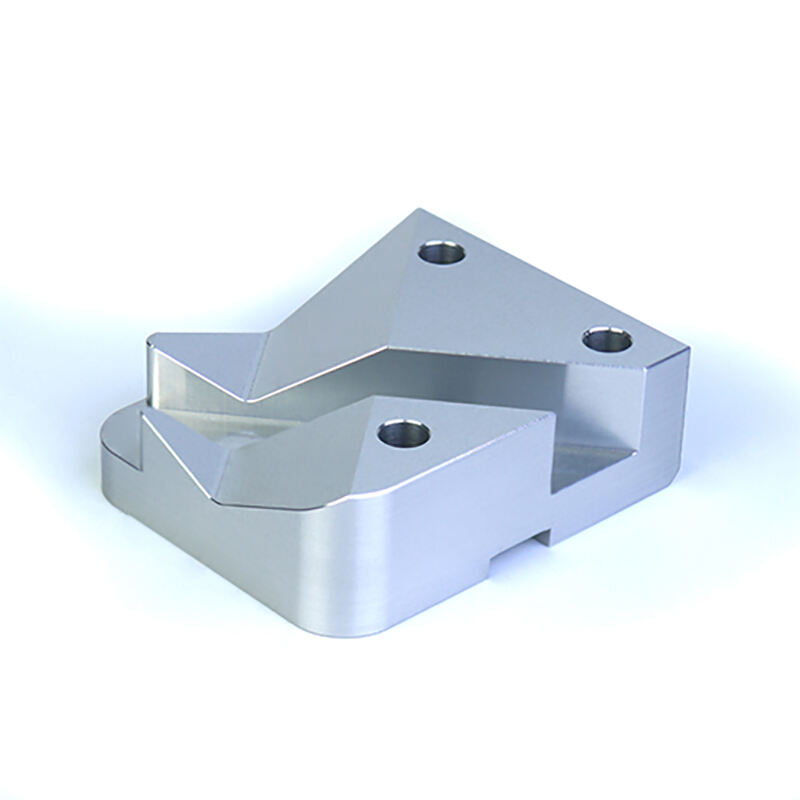

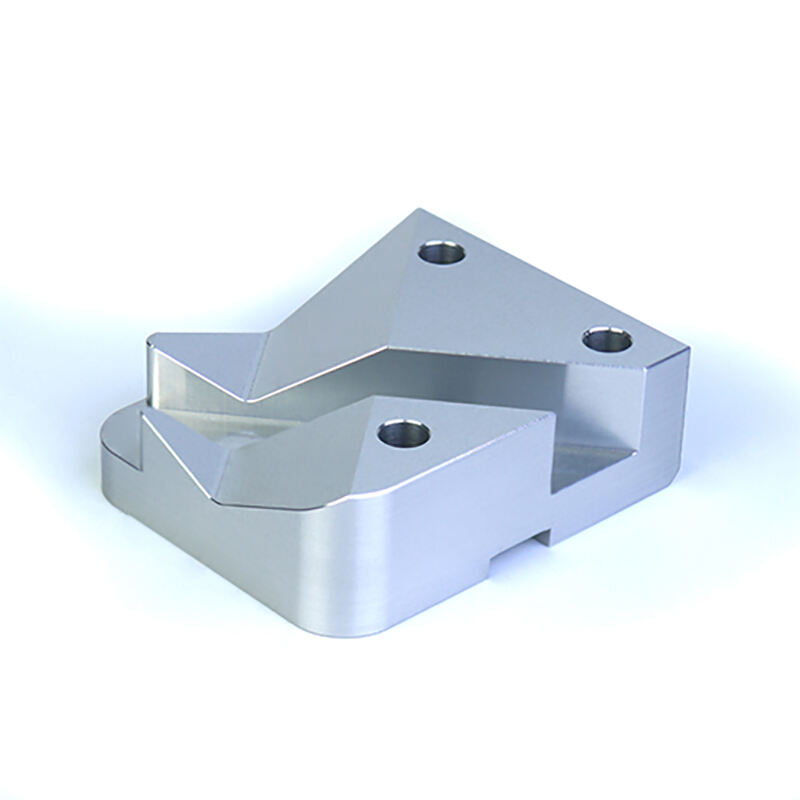

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In the evolving world of industrial production, precision, efficiency, and reliability are more critical than ever. One of the key technologies driving this precision is CNC milling—an advanced manufacturing process that produces high-accuracy components for a wide range of industries. As the demand for custom, complex parts increases, CNC milling parts have become the quality choice for manufacturers who prioritize performance and durability.

Professional manufacturing of CNC milling parts combines skilled engineering with advanced machinery and quality control systems. A reputable CNC manufacturer adheres to strict standards throughout the entire production process:

Design and Prototyping: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software ensures exact specifications are followed.

Material Selection: Only high-grade materials like aluminum, stainless steel, titanium, and engineering plastics are chosen based on the application’s needs.

Multi-Axis Capability: 3-, 4-, and 5-axis CNC machines allow for the creation of highly complex parts in fewer setups, improving both accuracy and efficiency.

Quality Assurance: Every part undergoes rigorous inspection using precision measurement tools, including CMM (Coordinate Measuring Machines), to ensure it meets all dimensional and functional requirements.

This professional approach results in parts that not only fit and function perfectly but also exceed the longevity and performance expectations of end users.

Choosing CNC milling parts means choosing quality, consistency, and repeatability. These are non-negotiable traits in industries where failure is not an option. Here’s why CNC milling remains a top-tier manufacturing solution:

High Tolerance Accuracy: CNC milling can achieve tolerances as tight as ±0.001 mm, making it ideal for precision engineering.

Surface Finish: The advanced tooling and control of CNC milling produce excellent surface finishes, reducing the need for secondary operations.

Versatility: From one-off prototypes to mass production, CNC milling is adaptable to a wide range of production scales and material types.

Cost-Efficiency in the Long Term: While initial setup may require investment, the accuracy and speed of CNC milling reduce scrap, labor costs, and rework.

Industries increasingly require parts that are not just functional, but also lightweight, durable, and ready for integration into larger systems. CNC milling supports this demand by enabling the production of parts with complex contours, tight tolerances, and consistent quality across batches. In aerospace, for instance, milled parts must meet strict weight and performance criteria. In the medical sector, components must be flawlessly accurate and biocompatible. CNC milling delivers on both fronts.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

· Simple prototypes: 1–3 business days

· Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

· 3D CAD files (preferably in STEP, IGES, or STL format)

· 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

· ±0.005" (±0.127 mm) standard

· Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog