Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

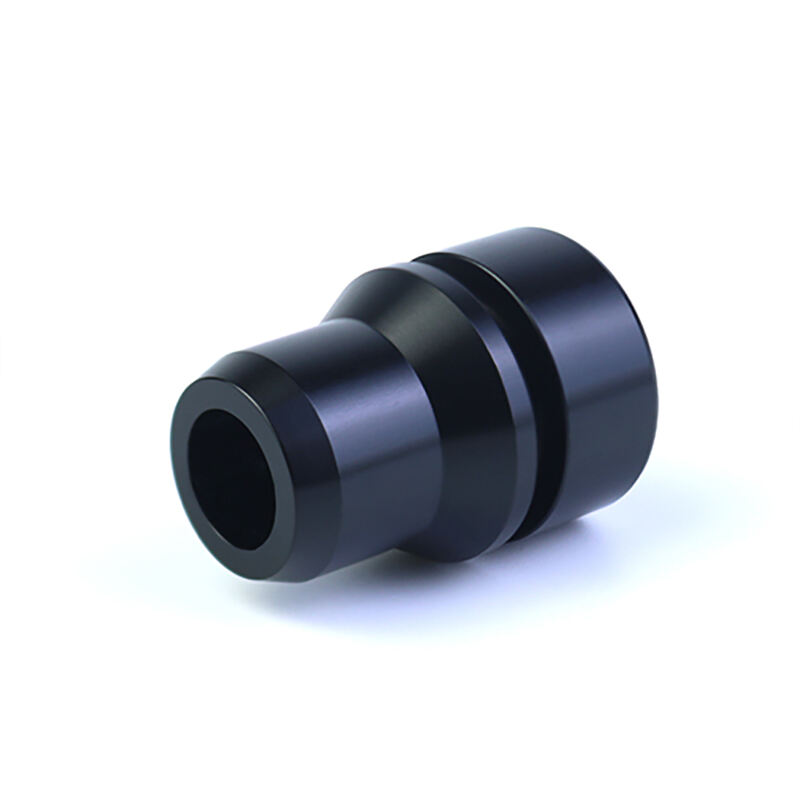

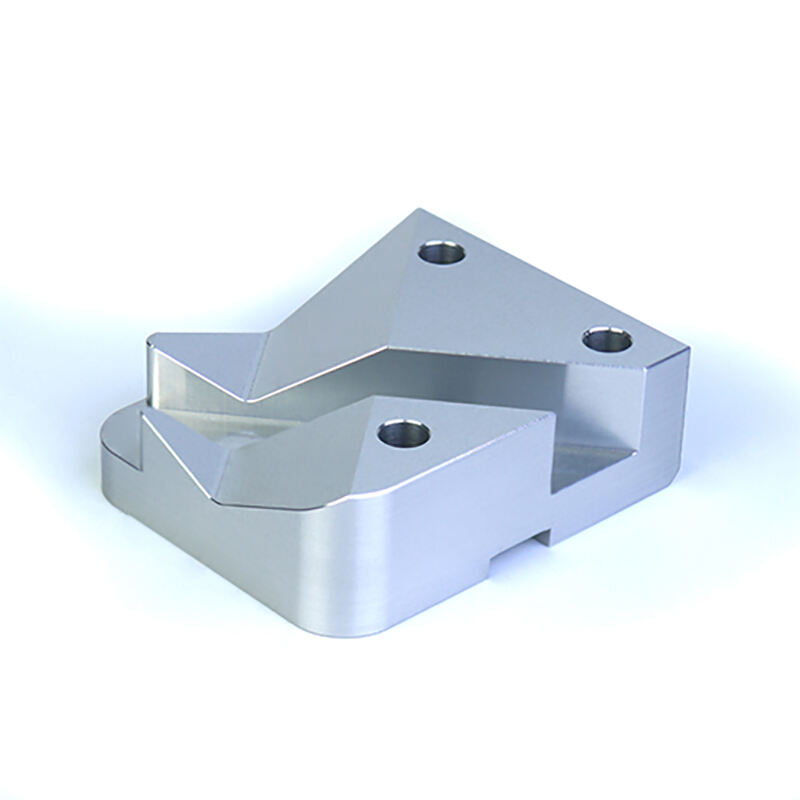

Precision Machining Parts

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material: stainless steel aluminum alloy brass metal plastic

Processing method :CNC Turning

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In today's highly competitive industrial landscape, the demand for precision-engineered components continues to grow across a variety of sectors, from aerospace and automotive to electronics and medical devices. At the core of this precision-driven revolution lies CNC turning technology —a vital process in modern manufacturing that delivers consistency, accuracy, and efficiency. The production of CNC turning parts is a cornerstone of this advancement, enabling manufacturers to meet tight tolerances and complex design requirements with confidence.

High Precision: CNC turning machines operate with incredible accuracy, often achieving tolerances within microns. This precision is critical in industries like aerospace and medical, where even minor deviations can compromise performance and safety.

Efficiency and Speed: Automated machining reduces human error and dramatically increases production speed. Complex geometries that once required multiple setups can now be completed in a single operation with CNC lathes.

Consistency and Repeatability: Once a CNC program is developed, it can be used repeatedly to produce identical parts—an essential quality in mass production and quality control.

Cost-Effective Production: By reducing waste, labor costs, and lead times, CNC turning contributes to overall cost-efficiency, especially for high-volume projects.

CNC turning parts are integral to a variety of high-performance systems. In the automotive industry, they are used in engine components, drive shafts, and transmission systems. In the medical field, precision-turned parts are found in surgical instruments and implantable devices. Electronics manufacturers use them in connectors, housings, and heat sinks. Their adaptability ensures that CNC turning continues to be a preferred manufacturing method across industries.

As smart manufacturing and Industry 4.0 technologies evolve, CNC turning is becoming more integrated with digital systems. Real-time monitoring, adaptive controls, and predictive maintenance are now being implemented to further optimize production efficiency. Additionally, the incorporation of sustainable practices, such as energy-efficient machines and recycling of materials, is shaping the future of CNC machining.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

· Simple prototypes: 1–3 business days

· Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

· 3D CAD files (preferably in STEP, IGES, or STL format)

· 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

· ±0.005" (±0.127 mm) standard

· Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog