Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

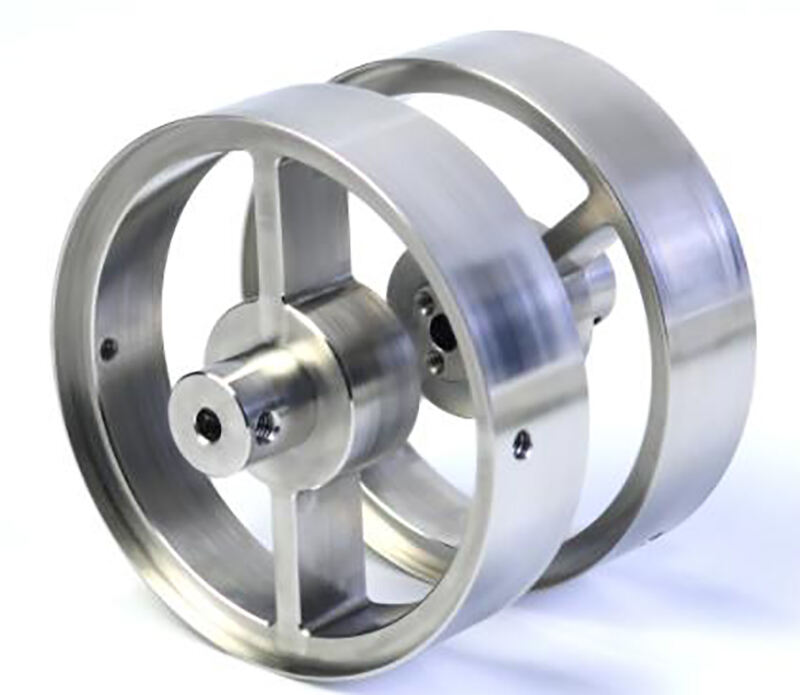

Machinery Axis: 3,4,5,6

Tolerance:+/- 0.01mm

Special Areas : +/-0.005mm

Surface Roughness: Ra 0.1~3.2

Supply Ability:500,000Piece/Month

1-Piece Minimum Order

3-Hour Quotation

Samples: 1-3 Days

Lead time: 7-14 Days

Certificate:ISO9001,AS9100D,ISO13485,ISO45001,IATF16949,ISO14001,RoHS,CE etc.

Processing Materials: aluminum, brass, copper, steel, stainless steel, iron, plastic, and composite materials etc.

If you’ve ever wondered how airplanes stay airborne or satellites orbit Earth flawlessly, the answer lies in aerospace precision parts. These tiny yet critical components ensure safety, performance, and reliability in one of the world’s most demanding industries. At PFT, we specialize in crafting these high-quality parts that keep the skies—and beyond—running smoothly.

From jet engines to satellite navigation systems, every piece of equipment in aerospace requires absolute accuracy. Even a minor flaw in a valve, bracket, or turbine blade can lead to catastrophic failures. That’s why manufacturers like us prioritize cutting-edge CNC machining, strict quality checks, and materials like titanium and advanced alloys. Whether it’s for commercial airlines, defense projects, or space exploration, aerospace precision parts must meet sky-high standards—literally.

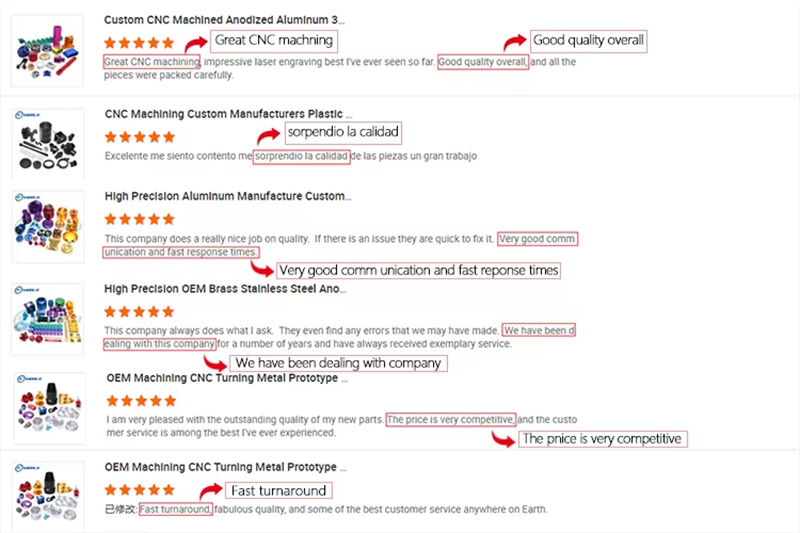

At PFT, we combine decades of engineering expertise with state-of-the-art technology. Our team understands that aerospace precision parts aren’t just products—they’re lifelines for pilots, astronauts, and passengers. Here’s what sets us apart:

1. Advanced Manufacturing: Our 5-axis CNC machines ensure micron-level accuracy.

2. Rigorous Testing: Every component undergoes stress tests, X-ray inspections, and compliance reviews.

3. Custom Solutions: Need a specialized part for a unique mission? We’ve got you covered.

Searching for “aerospace precision parts” online can feel overwhelming, but our goal is to make your job easier. We’re not just suppliers; we’re partners in innovation. With ISO 9001-certified processes and a commitment to fast turnaround times, we help clients worldwide meet tight deadlines without compromising quality.

The aerospace sector evolves rapidly, and so do material and design standards. Whether it’s lightweighting for fuel efficiency or adapting to new sustainability regulations, our factory stays ahead of trends to deliver future-ready components.

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings? Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog