Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Machinery Axis: 3,4,5,6

Tolerance:+/0.01mm

Special Areas : +/-0.005mm

Surface Roughness: Ra 0.1~3.2

Supply Ability:500,000Piece/Month

1-Piece Minimum Order

3-Hour Quotation

Samples: 1-3 Days

Lead time: 7-14 Days

Certificate:ISO9001,AS9100D,ISO13485,ISO45001,IATF16949,ISO14001,RoHS,CE etc.

Processing Materials: aluminum, brass, copper, steel, stainless steel, iron, plastic, and composite materials etc.

In today’s competitive manufacturing landscape, precision and reliability are non-negotiable. As a leading OEM provider specializing in custom CNC precision machined parts for aluminum and stainless steel applications, we combine cutting-edge technology with decades of expertise to deliver components that meet the strictest industry standards. Whether you’re in aerospace, automotive, or medical sectors, our solutions are engineered to elevate your projects .

Our factory is equipped with state-of-the-art 5-axis CNC machines and Swiss-style lathes, ensuring micron-level accuracy for complex geometries. Unlike generic suppliers, we focus on high-precision CNC machining tailored to your specifications, from prototypes to large-scale production. Key advantages include:

· Material Versatility: Expertise in machining aerospace-grade aluminum (6061-T6, 7075) and corrosion-resistant stainless steel (304, 316L) .

· Industry-Specific Solutions: Customized services for sectors like automotive (engine components) and medical (surgical instruments), addressing unique regulatory and performance needs .

Quality isn’t an afterthought—it’s embedded in every step. Our ISO 9001-certified quality management system integrates:

· In-Process Inspections: Real-time CMM (Coordinate Measuring Machine) checks to ensure dimensional accuracy.

· Surface Finish Expertise: Ra values down to 0.4 µm for critical applications like semiconductor equipment .

· Traceability: Full material certifications and compliance with RoHS/REACH standards for global clients .

From CNC-milled brackets to stainless steel hydraulic fittings, our capabilities span:

· Prototyping: Rapid turnaround for design validation (3-5 business days).

· High-Volume Production: Scalable solutions with lean manufacturing practices to reduce lead times by 30% .

· Custom Finishing: Anodizing, passivation, and powder coating to enhance durability and aesthetics .

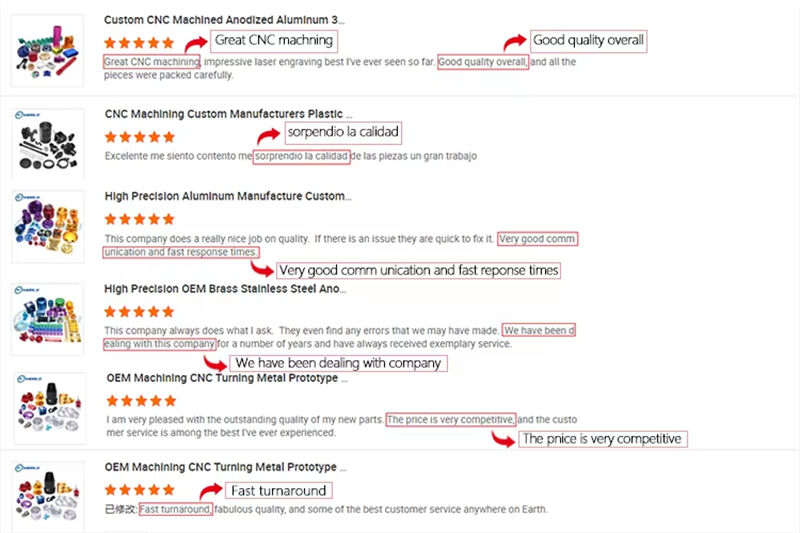

We prioritize partnerships over transactions. Our dedicated engineering support and 24/7 customer service ensure:

· Transparent Communication: Regular updates via ERP portals for real-time order tracking.

· After-Sales Guarantee: 12-month warranty on all parts, plus expedited rework for urgent needs .

· Competitive Pricing: Cost optimization through in-house tooling and bulk material sourcing .

· Proven Expertise: 15+ years serving Fortune 500 clients and SMEs globally.

· Sustainability Focus: Energy-efficient machining and recyclable material practices .

· Localized Support: Serving clients across the USA, Europe, and Asia with regional warehouses for faster delivery .

In a world where precision defines success, our factory stands as your trusted partner for custom CNC machining services. From concept to delivery, we’re committed to exceeding expectations. Ready to elevate your next project? [Contact us today] for a quote tailored to your needs.

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings? Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog