Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

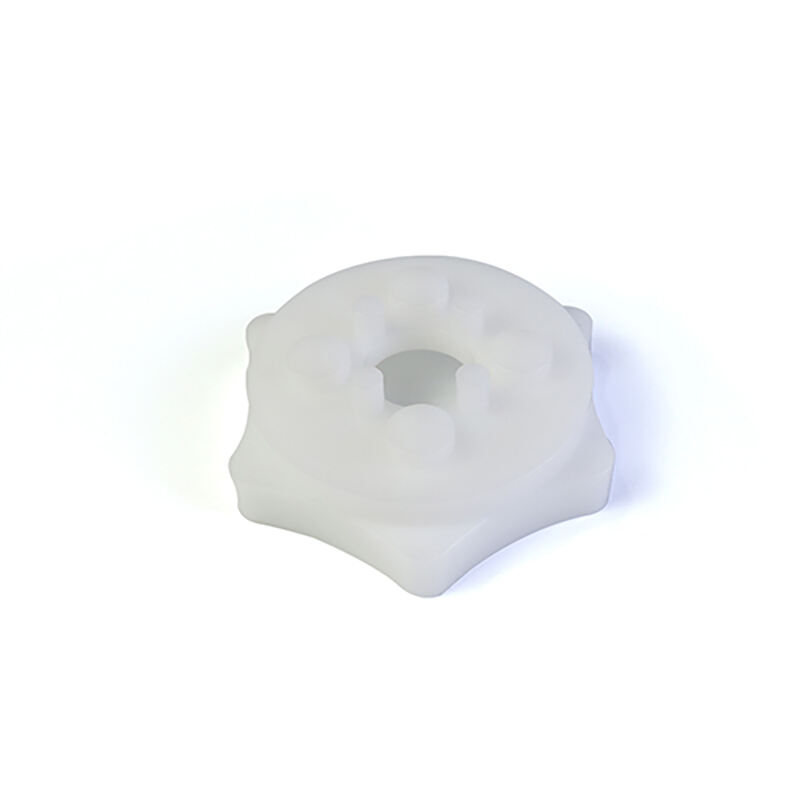

Precision Machining Parts

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material: Stainless steel

Processing method :CNC Turning

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In the world of manufacturing, plastic parts are ubiquitous. They are found in virtually every industry, from automotive to medical, consumer goods to electronics. However, creating plastic parts that meet specific requirements in terms of shape, size, and performance demands a high level of precision. This is where custom plastic parts machining comes into play.

Custom plastic parts machining refers to the process of designing and manufacturing plastic components that are tailored to meet the exact specifications of a particular application. This type of machining involves advanced techniques, specialized equipment, and a deep understanding of plastic materials to ensure the production of parts that are both high-quality and functional.

Custom plastic parts machining involves the use of various machining processes such as CNC Computer Numerical Control) machining, turning, milling, drilling, and grinding, to fabricate plastic components based on specific customer requirements. These processes allow for the creation of parts with complex geometries, tight tolerances, and smooth finishes, which are essential for applications where performance, durability, and accuracy are crucial.

Unlike mass production methods, which focus on creating large quantities of identical items, custom machining is designed for precision and customization. This means that manufacturers can produce one-off prototypes, low-volume production runs, or parts designed to fit unique or highly specialized needs.

The choice of material is critical when machining custom plastic parts. Plastics come in various types, each with its unique properties that make it suitable for different applications. Here are some commonly used plastic materials in custom machining:

• Acrylic (PMMA): Known for its optical clarity and ease of machining, acrylic is often used in applications requiring transparency, like optical lenses, display cases, and light covers.

• Polycarbonate (PC): Strong, tough, and impact-resistant, polycarbonate is ideal for applications that require durability, such as protective covers, lenses, and automotive parts.

• Nylon: Known for its toughness, low friction, and wear resistance, nylon is commonly used in automotive, industrial, and consumer goods applications, such as gears, bearings, and bushings.

• Acetal (Delrin): Acetal is a highly durable plastic with excellent mechanical properties, commonly used in precision components like gears, fasteners, and electrical connectors.

• Polyethylene (PE): Polyethylene is widely used for its chemical resistance and low friction properties. It's often found in medical, food processing, and industrial applications.

• PTFE (Teflon): PTFE is known for its non-stick properties, high chemical resistance, and high temperature tolerance. It's often used in seals, gaskets, and bearings.

• ABS (Acrylonitrile Butadiene Styrene): ABS is a tough plastic material that offers good strength, rigidity, and resistance to impact. It's commonly used in consumer products, automotive parts, and electronics housings.

• Polypropylene (PP): A lightweight, chemical-resistant plastic commonly used in packaging, medical devices, and automotive applications.

Several machining techniques can be employed to create custom plastic parts, depending on the complexity, material, and specifications of the part. Here are the key machining processes used in the production of custom plastic components:

1. CNC Milling

CNC milling is one of the most versatile methods for machining custom plastic parts. It involves the use of rotating cutting tools to remove material from a plastic workpiece, creating the desired shape. CNC milling is particularly effective for creating parts with complex geometries, such as contoured surfaces or holes in plastics like acrylic, polycarbonate, and nylon. It also provides a high level of accuracy and repeatability, making it ideal for both prototypes and low-volume production.

2. CNC Turning

CNC turning is used to create cylindrical plastic parts. The workpiece is rotated on a lathe, and a cutting tool is used to shape the plastic. This process is perfect for making components such as bushings, shafts, and rings. CNC turning is highly precise and can be used with materials like acetal, PTFE, and nylon, which are known for their excellent machinability.

3. Injection Molding

While not strictly a traditional "machining" method, injection molding is widely used in the production of custom plastic parts. In this process, melted plastic is injected into a mold under high pressure to create a part. Injection molding is ideal for high-volume production runs of complex shapes and intricate designs. It is commonly used for producing automotive parts, medical devices, and consumer products.

4. Laser Cutting

Laser cutting involves using a focused laser beam to precisely cut plastic materials. This technique is well-suited for cutting thin plastic sheets or for creating intricate designs in materials like acrylic and polycarbonate. Laser cutting offers an incredibly smooth finish and tight tolerances, making it an excellent choice for custom plastic parts that require precision and minimal post-processing.

5. Drilling and Tapping

Drilling is used to create holes in plastic components, while tapping is used to create threads inside holes. These processes are crucial for creating parts that need to be assembled or fastened, such as connectors, brackets, and housings. CNC drilling and tapping ensure that holes are accurate and consistently sized, even in hard-to-machine plastic materials.

6. Grinding and Polishing

Grinding and polishing are used to achieve smooth, high-quality finishes on custom plastic parts. Grinding removes material to refine the shape, while polishing helps to eliminate rough edges and improve surface aesthetics. This is particularly important for applications like display cases, lenses, or parts that require optical clarity.

Custom plastic parts machining offers numerous benefits, especially when precision and performance are key requirements. Some of the most significant advantages include:

1. High Precision

Machining processes like CNC milling, turning, and laser cutting allow manufacturers to produce parts with tight tolerances, often down to thousandths of an inch. This precision is critical in industries such as aerospace, medical, and electronics, where even minor deviations can lead to performance failures.

2. Complex Geometries

Custom plastic machining enables the creation of intricate shapes and designs that would be difficult or impossible to achieve through traditional molding processes. This capability is particularly valuable for products that require unique contours, holes, slots, or custom features.

3. Material Flexibility

Custom machining provides access to a wide range of plastic materials, each with distinct properties suited for different applications. Whether you need high-impact resistance, electrical insulation, or chemical resistance, machining can accommodate a variety of plastics to meet specific performance needs.

4. Low-Volume Production

Unlike injection molding, which typically requires large quantities for cost efficiency, custom plastic parts machining is well-suited for low-volume production. This makes it an ideal choice for prototyping, limited runs, and specialized components, reducing lead times and costs.

5. Improved Performance

With custom machining, plastic parts are fabricated to meet specific performance criteria, such as strength, flexibility, or heat resistance. This ensures that the components function optimally in their intended applications, whether they are exposed to extreme temperatures, heavy loads, or harsh chemicals.

6. Cost-Effective for Prototypes

For companies that are developing new products or testing designs, custom plastic machining offers a cost-effective way to produce prototypes. Unlike injection molding, which often requires expensive molds and tooling, machining allows for the rapid creation of functional prototypes without high upfront costs.

Custom plastic machining serves a wide range of industries and applications, including:

• Aerospace: Custom plastic parts like connectors, seals, and insulators are used in aerospace applications where lightweight, durability, and precision are essential.

• Medical Devices: Surgical instruments, diagnostic equipment, and implants require high-precision plastic components to ensure patient safety and device functionality.

• Automotive: Custom plastic parts for the automotive industry include dashboard components, seals, bearings, and more, offering lightweight alternatives to metal parts.

• Electronics: Housing for electronic devices, connectors, and enclosures made from plastics like ABS or polycarbonate are common in consumer electronics.

• Food and Beverage: Custom plastic components used in food processing equipment, packaging, and dispensers must meet regulatory standards for safety and hygiene.

• Industrial Equipment: From gears and bearings to casings and housings, custom plastic parts are used in a wide array of industrial machinery for performance and reliability.

Q:When should I use custom plastic machining instead of injection molding?

A:Custom plastic machining is often preferred in the following scenarios:

· Prototypes and Low-Volume Runs: When a small number of parts are needed, and the cost of mold creation for injection molding is not justified.

· Complex or Intricate Designs: For parts that have complex geometries, tight tolerances, or intricate details that would be difficult to achieve with molding.

· Material Variety: When a specific plastic material or material grade is required for performance reasons, and the material isn't suitable for injection molding.

· Shorter Lead Times: Machining can often be faster for prototyping and low-volume production compared to the long setup times required for injection molding.

Q:How precise are custom plastic parts produced by machining?

A:Custom plastic parts machining can achieve extremely tight tolerances, often in the range of ±0.001 inches (0.025 mm) or better, depending on the material, machining process, and equipment used. This level of precision is critical for industries like aerospace, medical devices, and electronics, where even the smallest deviation from the intended specifications can lead to product failure.

Q:What is the typical lead time for custom plastic machining?

A:The lead time for custom plastic machining varies depending on several factors, such as:

· The complexity of the part and the machining process required.

· The material chosen for the part.

· The volume of parts required (prototypes vs. production runs).

· The availability of tooling and equipment.

For prototyping, lead times can range from a few days to a couple of weeks. For small production runs, it typically takes 2 to 4 weeks, although faster turnaround times may be possible with optimized workflows and priority scheduling.

Q:What are the cost factors involved in custom plastic machining?

A:The cost of custom plastic machining depends on several factors, including:

· Material Choice: Different plastics vary in cost, with specialty materials like PEEK or PTFE being more expensive than common plastics like ABS or nylon.

· Complexity: More intricate designs that require advanced machining techniques will increase production time and cost.

· Quantity: While machining is cost-effective for small production runs, larger quantities may reduce the cost per unit. However, machining generally remains more expensive than injection molding for high-volume production.

· Lead Time: Faster turnaround times may require additional resources and expedited processing, which can increase the cost.

Q:Can custom plastic parts machining be used for both prototypes and production runs?

A:Yes, custom plastic machining is versatile and suitable for both prototypes and production runs. It's particularly beneficial for:

· Prototypes: Machining allows for rapid prototyping, enabling you to test designs, evaluate form, fit, and function, and make any necessary adjustments before moving to full-scale production.

· Small-Scale Production: For low- to medium-volume production, custom plastic machining offers flexibility and precision, without the high setup costs associated with molding.

Q:Can custom plastic parts machining handle complex geometries?

A:Yes, custom plastic machining excels at producing parts with complex geometries that may be challenging for other manufacturing methods. With CNC machining, 3D CAD designs can be translated into precise parts, allowing for intricate shapes, multi-dimensional cuts, and customized features. This makes machining particularly well-suited for parts with fine details, tight tolerances, or non-standard designs.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog