Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

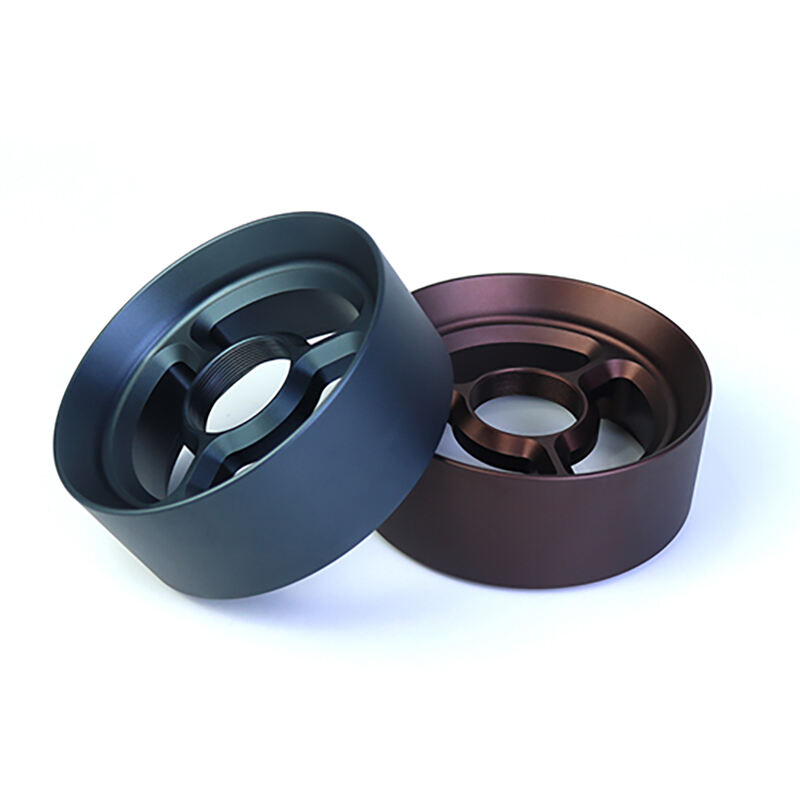

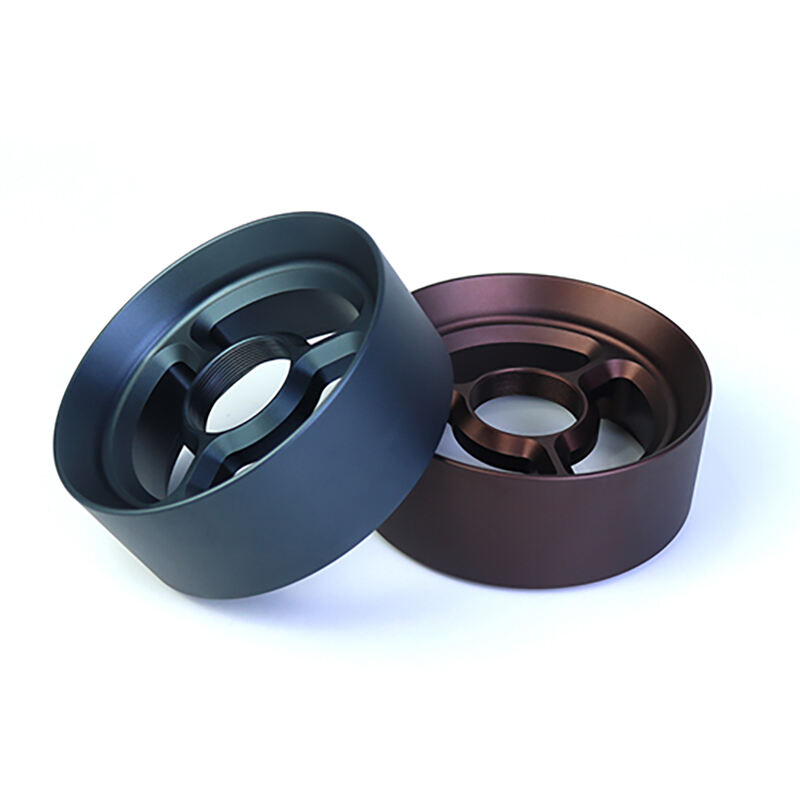

Precision Machining Parts

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material: stainless steel aluminum alloy brass metal plastic

Processing method :CNC Turning

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In today’s fast-paced world, precision and customization are no longer luxuries—they’re necessities. Whether you’re building prototypes scaling up production, or working on niche projects, customized CNC parts have become the go-to solution for industries ranging from aerospace to automotive.

CNC (Computer Numerical Control) machining is all about precision. Unlike traditional methods that rely on manual tools and molds, CNC machines use computer-guided cutting tools to create parts with extreme accuracy. For example, some CNC milling parts can achieve tolerances as tight as ±0.01mm ensuring consistency and reliability .

One of the biggest advantages? Speed and flexibility. Since CNC machines don’t require new tooling for every design change, modifications can be implemented quickly. This is especially useful in research and development or when customizing products for small markets . Imagine needing a prototype overnight—CNC machining can deliver it faster than ever before.

You don’t need to order thousands of parts to benefit from CNC. Even for low to medium production volumes, CNC machining is often more economical than methods that require expensive molds or tooling. Startups and specialized manufacturers love this because it lowers the barrier to entry without sacrificing quality.

From aerospace components to medical devices, CNC parts are used everywhere. For instance, titanium casings for luxury watches or aluminum parts for automotive engines rely on CNC’s ability to handle complex geometries and tight tolerances . Even in medical fields, customized precision components are critical for ensuring safety and functionality.

• Material Versatility: CNC machines can work with aluminum, steel, brass, and more, allowing for tailored solutions.

• Surface Finishes: Options like anodizing, plating, or polishing let you match the aesthetic and durability of your project.

• Rapid Delivery: Many providers offer 7–15 day lead times for CNC-machined parts, making them ideal for urgent projects.

If you’re ready to explore CNC machining, here’s what to ask for:

• A 3D drawing of your part.

• Tolerance specifications (e.g., ±0.01mm).

• Surface finish requirements (e.g., polished or anodized).

With its blend of speed, precision, and adaptability, customized CNC parts are transforming how we build and innovate. Whether you’re a designer, engineer, or manufacturer, now’s the time to embrace this powerful technology.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog