Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

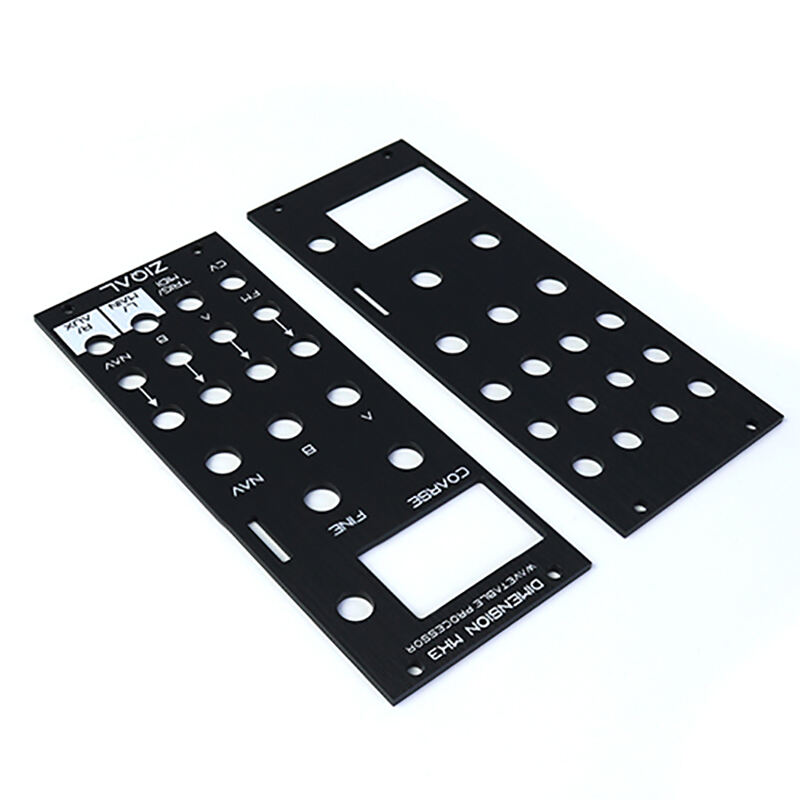

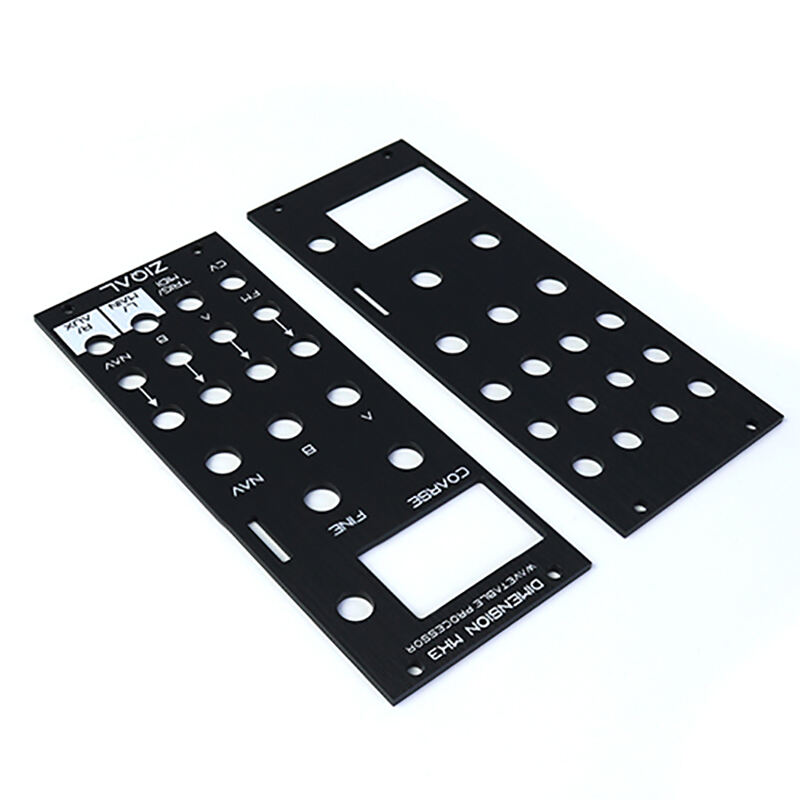

Precision Machining Parts

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material: stainless steel aluminum alloy brass metal plastic

Processing method :CNC Turning

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In today's era of high reliance on precision manufacturing electronic CNC parts have become an indispensable part of many industries. Whether it is automobiles, electronic equipment or aerospace, these parts play a vital role. If you are looking for a factory that can provide high-quality, high-precision electronic CNC parts then you have come to the right place.

We are a professional factory focusing on the manufacture of electronic CNC parts with advanced production equipment and exquisite production technology. From design to finished product, we always adhere to the concept of "professional manufacturing quality choice", and strive to provide customers with the most reliable products and services.

In our factory, each piece of equipment is strictly screened and regularly maintained to ensure that it is always in the best condition. We have introduced high-precision CNC machine tools that can achieve micron-level processing accuracy to meet customers' extreme requirements for product details. Whether it is complex surface processing or precise hole processing, we can easily handle it.

We are well aware that product quality is the lifeline of the company. Therefore, we not only invest a lot of money in equipment, but also strive for excellence in technology. Our engineering team has rich industry experience and can customize the most suitable processing plan according to the specific needs of customers. From the selection of raw materials to the testing of finished products, every link is strictly controlled to ensure that the final product meets or even exceeds customer expectations.

In order to ensure the stability of product quality, we have established a complete quality control system. From the storage of raw materials to the delivery of finished products, each process is responsible for a dedicated person and has passed ISO 9001 and other international quality management system certifications. We also provide full-process quality tracking services, so that customers have no worries during the use of the product.

We not only focus on the manufacturing of electronic CNC parts, but also provide a variety of products, including but not limited to:

• Precision molds: suitable for multiple industries such as electronics and automobiles

• Customized metal processing parts: meet the special needs of different customers

• Aerospace-grade parts: suitable for fields with high precision and high reliability requirements

Whether you need standard parts or customized parts, we can provide you with the right solution.

We not only pay attention to the quality of the product, but also attach importance to the customer experience. We provide a perfect after-sales service system, including:

• Quick response mechanism: After receiving customer inquiries or questions, we will respond in the shortest time

• Technical support: Our engineering team is on call at any time to provide customers with technical support and suggestions

• Product warranty: We provide a certain period of product warranty service to ensure that customers have no worries

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog