Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

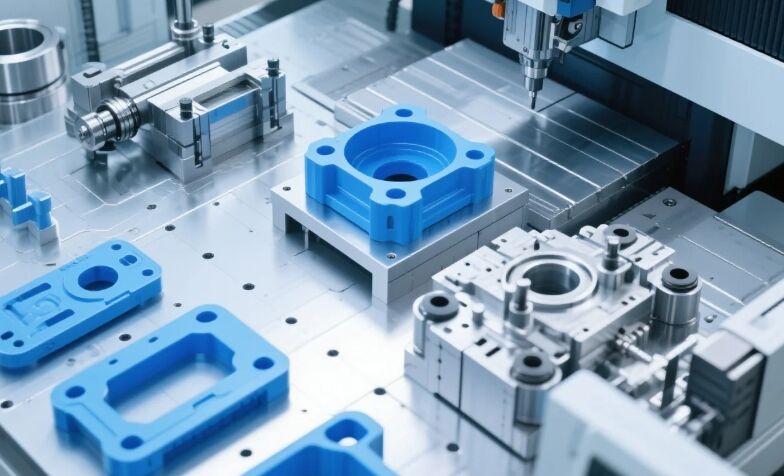

When developing new products, getting functional prototypes quickly can make or break your project timeline. At PFT, we specialize in high-performance plastic and metal rapid prototypes that bridge the gap between design and production. With 85% strength retention compared to final molded parts, our prototypes let you conduct real-world testing without compromising on durability.

Advanced Multi-Technology Approach

Combining CNC machining, metal laser sintering, and industrial 3D printing (SLS/FDM/SLA), we overcome traditional limitations of material options and size constraints.Whether you need aluminum functional parts or complex nylon components, our 0.1-0.2mm layer precision ensures production-grade accuracy.

Accelerated Production Timeline

Unlike traditional shops slowed by tooling delays, our digital prototyping workflow eliminates information silos.Most orders ship within 5-7 working days – crucial when facing tight product launch windows.

Cost-Effective Low-Volume Solutions

Our aluminum injection molding reduces tooling costs by 40% compared to steel molds , making short runs economically viable.

We solve critical challenges other providers overlook:

A client needed watertight nylon prototypes for environmental testing. Competitors quoted 3 weeks; we delivered in 8 days using multi-jet fusion technology. The parts withstood 150°C and IP67 testing, allowing immediate production ramp-up.

| Technology | Materials Supported | Tolerance | Max Part Size |

|---|---|---|---|

| CNC Machining | Aluminum, Brass, POM, Nylon | ±0.05mm | 600x500x300mm |

| Metal SLS | Stainless Steel, Titanium | ±0.1mm | 300x300x300mm |

| Industrial FDM | ABS, PC-ABS, ULTEM 1010 | ±0.15mm | 900x600x900mm |

Unlike generic shops, we provide dedicated engineering support throughout your project:

Ready to accelerate product development?

→ Contact our team for a free project review

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

|||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||

Titanium: Grade F1-F5 | ||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | ||||

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|||

Tolerance |

±0.002 ~ ±0.005mm |

|||

Surface Roughness |

Min Ra 0.1~3.2 |

|||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog