Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

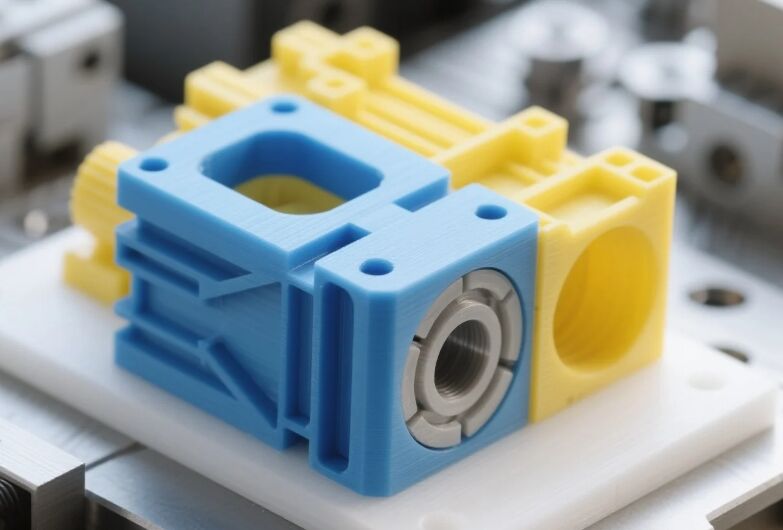

In today’s fast-paced product development cycle, waiting weeks for prototypes can derail innovation. At PFT, we’ve redefined rapid manufacturing with functional prototype models that bridge design and production. Whether you need quick-turn CNC machining for aerospace-grade metals or complex 3D-printed prototypes overnight, our fusion of advanced technology and hands-on expertise delivers parts that work, not just look good.

Every prototype undergoes a 3-stage checkpoint:

When you receive your prototype, our support begins:

While robots handle precision, our craftsmen bring decades of experience:

"Last month, an aerospace client needed a drone armature in 48 hours – a job others rejected. Our team modified the toolpath overnight, saving their flight test schedule. That’s the hustle you won’t find in algorithms."

– Alexander.Luna, Lead Manufacturing Engineer

Don’t settle for slow or superficial prototypes. Get functional, production-grade parts in days:

? Request Your Quote :https://www.7-swords.com/contact

? Call Our Prototyping Team: +86 18926459278

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

|||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||

Titanium: Grade F1-F5 | ||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | ||||

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|||

Tolerance |

±0.002 ~ ±0.005mm |

|||

Surface Roughness |

Min Ra 0.1~3.2 |

|||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog