Մեր թերության մակարդակը պահվում է 0,3 %-ից ցածր՝ հավաստիացնելով հաճախորդների վստահությունը կայուն մատակարարման շնորհիվ:

Պաշտոնական մակարդակի ցածր քան 0,3% հասնելը. Ինչպես ենք վստահություն շահում կայուն մատակարարման շնորհիվ

Երբ հաստատականությունը որոշում է մրցունակությունը

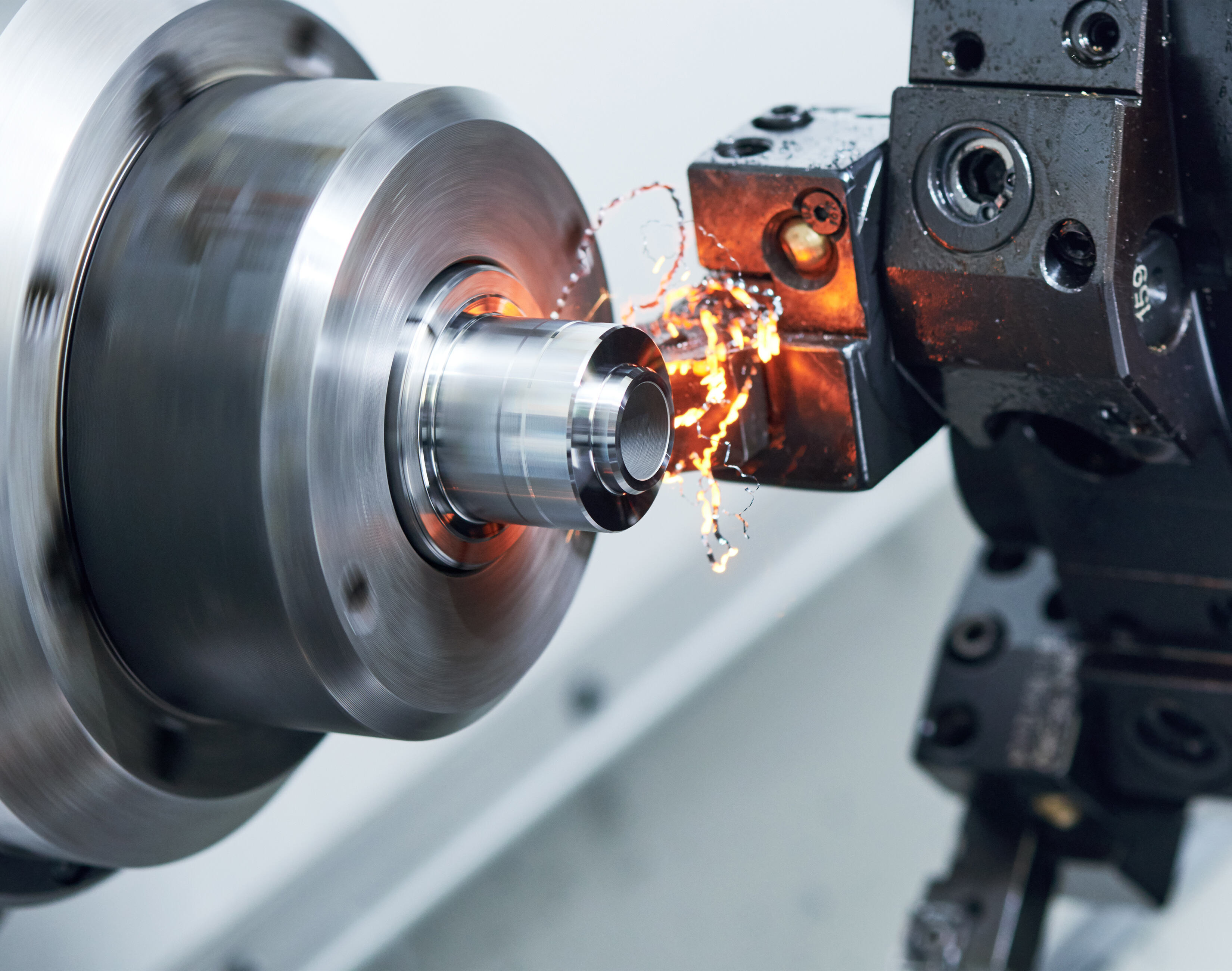

Կարող եք լսել դա այն պահին, երբ մեքենաները միանում են՝ սինքրոնացված CNC սեղմակների մշտական ձայնը, որոնք կտրում են մետաղական վահանակները, ճշգրիտ կլիկները՝ յուրաքանչյուր հանգույցի ճշգրտությունը ստուգելու համար։ Մեր նման արտադրության միջավայրում հաստատականությունը ոչ միայն նպատակ է, այլ գոյատևման հարց:

Ուստի մենք մեր ամբողջ արտադրական համակարգը կառուցել ենք մեկ չափելի նպատակի շուրջ. պահելով մեր թերությունների մակարդակը 0,3%-ից ցածր:

1. Հիմքը՝ գործընթացի վերահսկում, որը կարող եք ստուգել

Տարիներ շարունակ մենք սովորել ենք, որ «զրոյական թերություն»-ը շղթայական կեղծանուն չէ — դա համակարգ է:

Մեր արհեստանոցը ինտեգրում է տողային ստուգում , ավտոմատացված SPC (Վիճակագրական գործընթացի վերահսկում) , և գործիքի մաշվածության հսկում մշակման յուրաքանչյուր փուլում

Օրինակ՝ ռոբոտական միացումների համար ճշգրիտ առանցքների մշակման ընթացքում մեր սենսորները իրական ժամանակում հայտնաբերում են գործիքի մաշվածության շեղումները, որոնք գերազանցում են 3 մկմ հայտնաբերման դեպքում համակարգը ավտոմատ կերպով կարգավորում է շեղումները կամ ակտիվացնում է գործիքի փոխարինումը հաջորդ ցիկլից առաջ

Արդյունքը

մեր միջին սխալման մակարդակը 0,27% է ինչը հաստատված է ներքին ամսական աուդիտների և երրորդ կողմի որակի զեկույցների միջոցով

կայուն մատակարարումը սկսվում է կանխարգելի ճշգրտությունից

Կայուն մատակարարման շղթան կախված է կանխատեսելիությունից .

Մենք իրականացրեցինք PPAP (Արտադրության մասերի հաստատման գործընթաց) մոտեցում, որը նման է ավտոմոբիլային ստանդարտին, որպեսզի ապահովվի, որ յուրաքանչյուր մասերի խմբաքանակ ժամանակի ընթացքում պահպանի կայուն կատարումը:

Յուրաքանչյուր արտադրական խմբաքանակ ներառում է.

-

Նմուշի սկզբնական ստուգում (FAI) լրիվ չափագիտական զեկուցումներով

-

Խմբաքանակի հետևողականության համակարգ նյութերի կապը մշակման պարամետրերի հետ

-

24-ժամյա լարվածության թեստեր բարձր բեռնվածության մասերի համար

Այս կառուցվածքը նշանակում է, որ երբ հաճախորդը պատվիրում է 5,000 հատ ստեղծված CNC մաս , նրանք չեն ստանում 4,950 լավ և 50 արտահեղություններ — նրանք ստանում են 5,000 հատ հավաքակազմի համար պատրաստ մասեր, որոնք ստուգված են ըստ սպեցիֆիկացիայի:

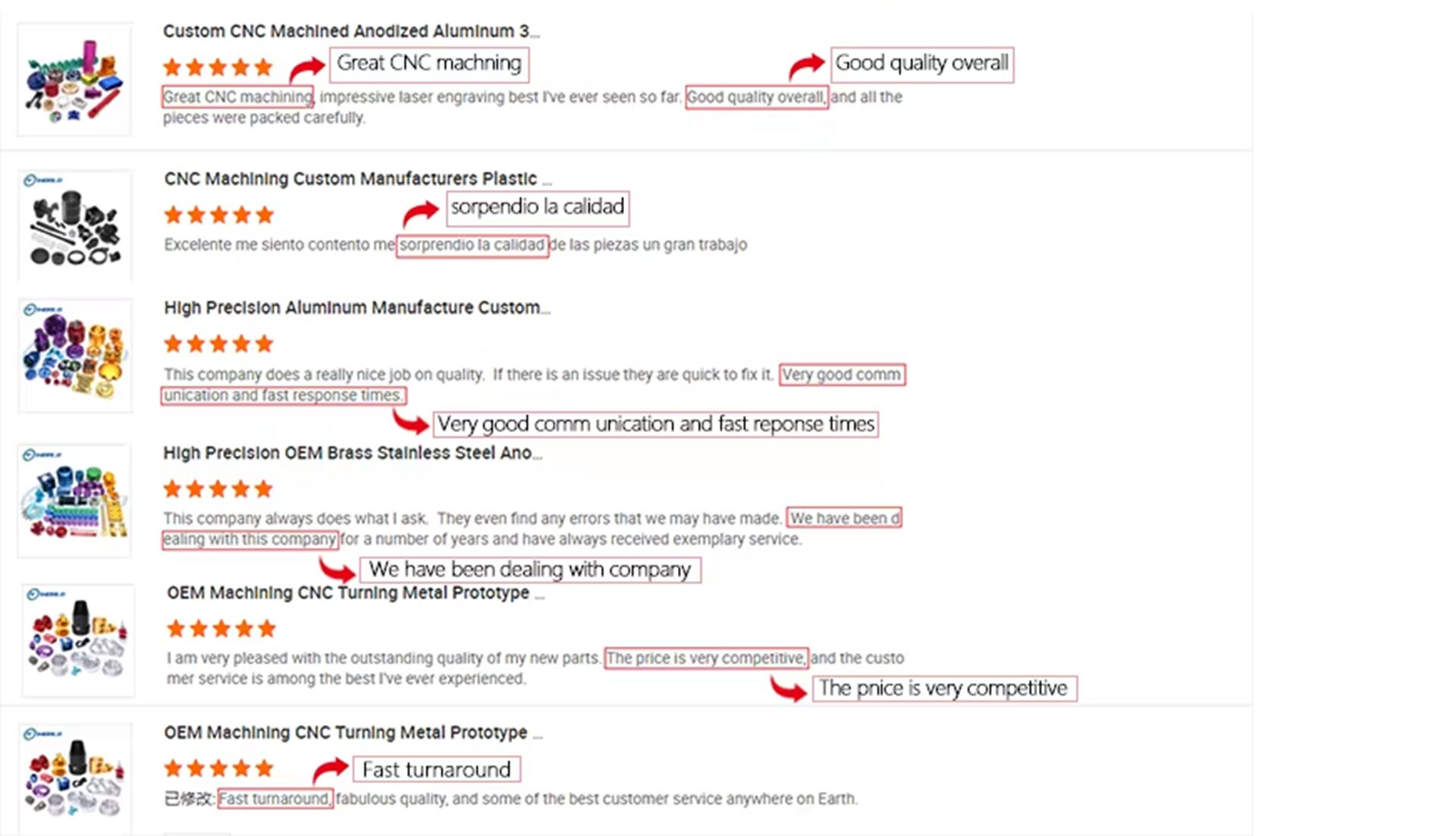

3. Տվյալներով աջակցված վստահություն՝ այն թափանցիկությունը, որը կարող են տեսնել գնողները

Գնումների թիմերը այսօր ուզում են ոչ միայն արագ առաքում, այլ նաև ապացույց հուսալիության մասին:

Դրա համար էլ մենք կիսվում ենք ամսական որակի վիզուալ տվյալներով մեր հիմնական հաճախորդների հետ, որոնք մանրամասնում են.

-

Ելքի ցուցանիշի գծեր

-

Գործընթացային կարողություն (Cp, Cpk)

-

Ուղղիչ միջոցառումների հետևում

Վերջերս մեկ աուդիտի ընթացքում եվրոպական OEM գործընկերոջ հետ մեր Cpk միավորը՝ 1.83-ը բոլոր պտտման գծերում, նշվել է որպես «բացառիկ կայունություն» իրենց մատակարարների գնահատման զեկույցում:

Այս թափանցիկությունը ստեղծում է վստահության մի մակարդակ, որն անցնում է գնից ավելին՝ սա ապացուցված արդյունավետություն է տվյալներով:

4. Տեխնոլոգիան, որն ապահովում է ճշգրտություն

Մենք անընդհատ թարմացնում ենք մեր արտադրական և ստուգման սարքավորումները՝ պահպանելու մեր 0,3%-ի համար համարվող հիմնաչափը.

-

5-առանցքանի CNC կենտրոններ (DMG MORI, Mazak)՝ բարդ կոնտուրային ճշգրտության համար

-

Zeiss CMM ստուգում մինչև ±0.002 մմ

-

Իրական ժամանակում MES տվյալների հետևում կապելով յուրաքանչյուր կայանը թվային վահանակի հետ

Անցումը WebP-հիմնված տեսողական որակի ստուգման զեկույցներին նաև օգնում է ավելի արագ տրամադրել ստուգման տվյալները հաճախորդներին՝ զեկույցների ժամանակը կրճատելով 40%և արագացնելով վերապատվերի որոշումների ընդունումը

5. Ինչ է նշանակում սա մեր հաճախորդների համար

Գնումների կառավարիչի համար «կայուն մատակարարման» երաշխիքը չի ներկայացնում աբստրակտ գաղափար՝ այն ուղղակիորեն նշանակում է ավելի քիչ արտադրության դադար , ավելի ցածր հավաքակցման վերամշակում , և կանխատեսելի առաքման ժամկետներ .

Երբ դուք ձեռք եք բերում մասեր մատակարարից, որն ապահովում է 0,3%-ից ցածր թերությունների մակարդակ, դուք պարզապես մասեր չեք գնում՝

դուք գնում եք գործողությունների երաշխիք .

Հիմնական գրավում

Տվյալների հիման վրա գործընթացների կառավարման, թափանցիկ հաշվետվությունների և սարքավորումների անընդհատ թարմացումների շնորհիվ մենք վաստակել ենք համաշխարհային հաճախորդների երկարաժամկետ վստահությունը:

0,3%-ից ցածր թերությունների մակարդակը մեր նպատակը չէ՝ այն մեր երաշխիքն է:

Հաճախ տրամադրվող հարցեր

Հարց 1. Ինչպե՞ս եք ձեզ հաջողվում պահպանել այդքան ցածր թերի մակարդակ:

Մենք օգտագործում ենք իրական ժամանակում ընթացիկ վիճակի վերահսկողություն (SPC), ինքնաշխատ գործիքի տեղաշարժի վերահսկողություն և հիմնարար չափերի 100% ստուգում:

Հարց 2. Կարո՞ղ եք ստուգման տվյալները կիսել գնորդների հետ:

Այո: Բոլոր լոտերը թվային ստուգման զեկույցներով են (CMM + տեսողական որակի վերահսկում), որոնք հասանելի են մեր հաճախորդների վահանակի միջոցով:

Հարց 3. Ինչպե՞ս եք ապահովում խմբաքանակի պատվերների համար կայուն առաքումը:

Մենք օգտագործում ենք կանխատեսվող սպասարկում և ինքնաշխատ պլանավորում՝ ապահովելու սարքավորումների ակտիվ աշխատանքի 98%-ից ավելի ցուցանիշ:

PFT Precision, ձեր վստահելի գործընկերը պատվիրված CNC մշակման մեջ

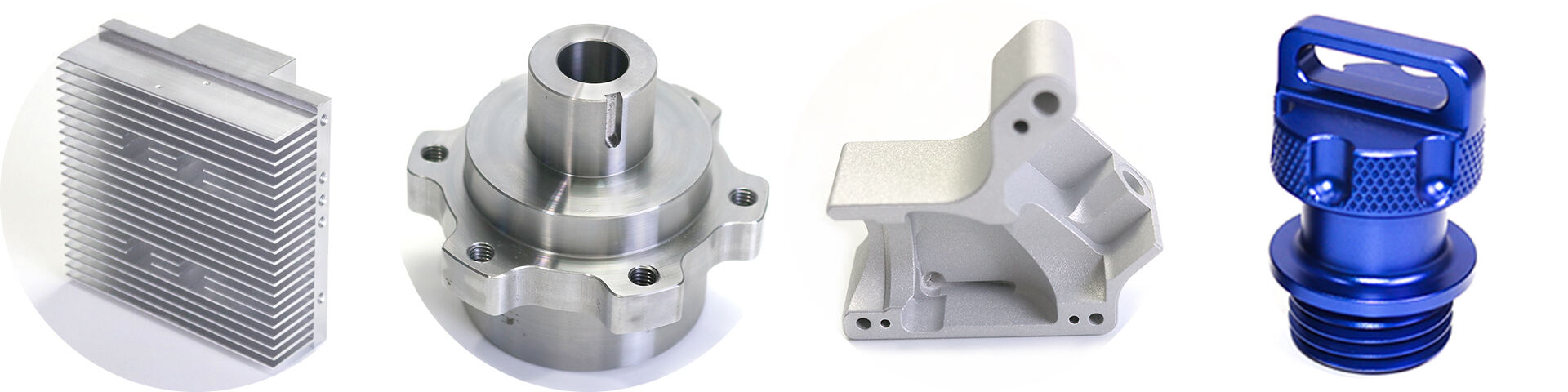

Որպես պատվիրված CNC մշակման մասերի և բաղադրիչների առաջատար մատակարար, PFT Precision-ը մասնագիտացած է սկզբնական փորձարկումների և ֆրեզային մշակման բարձրորակ մետաղական նյութերի վրա: Մենք մատակարարում ենք ճշգրիտ նախագծված արտադրանքներ՝ հարմարեցված տարբեր ոլորտների յուրահատուկ պահանջներին: Մեր հավատարմությունը բարձր որակին հնարավորություն է տվել մեզ հաստատել մեզ որպես շուկայի առաջատար CNC արտադրողներից մեկը:

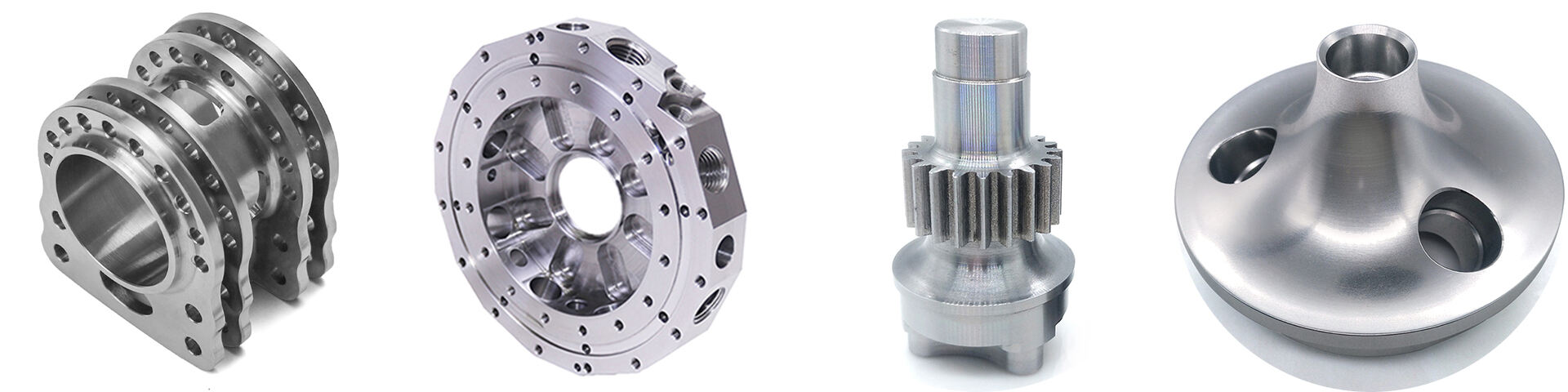

Մեխանիզմի առանցք: 3,4,5,6

Թողունակություն +/- 0.01 մմ

ՍPECIAL Տարածքներ: +/-0.005մմ

Մակերևույթի հատկություն: Ra 0.1~3.2

Մատակարարման կարողություն: 300000Կտոր/Ամիս

Առանձնացված ճշգրիտ մասեր

Հաշվետվություն Գարանտիա:

Հաստատուն հետապատolgություն послe-վաճառք

Մենք պարծենում ենք նրանով, որ մեր CNC մշակման ծառայությունների համար ստացել ենք մի քանի արտադրության վկայականներ, ինչը ցույց է տալիս մեր նվիրումը որակի և հաճախորդների բավարարմանը: Մեր թիմը հետևում է խիստ որակի վերահսկման ընթացակարգերին՝ ապահովելով, որ արտադրած յուրաքանչյուր մասը համապատասխանում է որակի և ճշգրտության ամենաբարձր չափանիշներին

|

Մշակում

|

CNC چرخان, CNC կորում, լեզուցի կտրում, ծագում, պտույտ, սیրեն կտրում, դրոշք, էլեկտրոնային հաղորդակցության մեխանիզմ (EDM), մոլդավորում

|

|||||||

|

Նյութեր

|

Ալյումինիում՝ 2000 շարք, 6000 շարք, 7075, 5052 և այլն

|

|||||||

|

Շիկացված պողպատ՝ SUS303, SUS304, SS316, SS316L, 17-4PH և այլն

|

||||||||

|

Պողպատ՝ 1214L/1215/1045/4140/SCM440/40CrMo և այլն

|

||||||||

|

Երկաթ: 260, C360, H59, H60, H62, H63, H65, H68, H70, Բրոնզ, Մեդ

|

||||||||

|

Տիտան: F1-F5 գրադացիոն

|

||||||||

|

Պլաստմասսա՝ Acetal/POM/PA/Նայլոն/PC/PMMA/PVC/PU/Ակրիլ/ABS/PTFE/PEEK և այլն

|

||||||||

|

Մակերևույթի մշակման

|

Օքսիդացված, Փոշի փչող մաքրում, Ծանրագրություն, PVD պլատինապատում, Ցինկ/Նիկել/Քրոմ/Տիտան պլատինապատում, Խոզանակով մաքրում, Ներկում, Փոշիային ծածկույթ, Պասսիվացում, Էլեկտրաֆորեզ, Էլեկտրական փայլակ, Շեղատ, Լազերային/Խորագրություն/Խորակոփում և այլն

|

|||||||

|

Համոզագույնություն

|

±0.002 ~ ±0.005 մմ

|

|||||||

|

Մակերեսի դաժանություն

|

Մին Ra 0.1~3.2

|

|||||||

Վստահեք փորագրման մեջ փորագրման մասնագետներին

Ալյումին

Եղցանիքի արծաթ/Արծաթ/Տիտան դաշնակցություն

1214L/1215/1045/4140/SCM440/40CrMo և այլն

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B և այլն

Ծաղիկ/Կոպր

Պլաստիկ

CNC մեխանական մասերի մակերեսի -ENDASNAVORCES.

Մանրամասն նկարներ (PDF/STEP/IGS/DWG...), ներառյալ որակը, առաքման ժամկետը, նյութերը, որակը, քանակը, մակերեսային մշակումը և այլ տեղեկություններ