איזו מכונת CNC מתאימה ביותר לרכיבים מדויקים במיוחד בתעשיית התעופה והחלל?

המאמץ המתמיד של תעשיית התעופה והחלל לרכיבים קלים, חזקים ואמין יותר מציב דרישות יוצאות דופן על ציוד ייצור. עם סובלנות שמתקרבת באופן שגרתי ל ±0.025mm וחומרים שמתנים מ сплавי אלומיניום עד סופר-сплавים בעלי טמפרטורה גבוהה , בחירת מכונות CNC מתאימות הופכת להחלטה אסטרטגית קריטית. ככל שאנו מתקדמים דרך שנת 2025, יצרנים ניצבים בפני לחץ גובר לאפשר חיסכון במדויק ובתפוקה תוך שמירה על עמידה בתקנים איכות מחמירים בתחום תעופה וחלל. ניתוח זה משווה בצורה שיטתית בין טכנולוגיות CNC מובילות טכנולוגיות CNC כדי לזהות יישומים אופטימליים עבור רכיבי תעופה שונים מסוגים, ומספק תובנות המבוססות על נתונים לצורך החלטות השקעה בת капитал.

שיטות מחקר

1. מסגרת הערכת

המחקר השתמש בגישה מקיפה להערכה:

• בדיקת דיוק ממדי לאורך מספר סרטי ייצור

• מדידת גימור משטח באמצעות פרופילומטריה מגעית ולא מגעית

• ניתוח קצב הסרת חומר עבור שיקועים תעופתיים שונים

• מעקב אחר זמני ההכנה ויעילות המעבר בין עבודות

2. ציוד וחומרים

ההערכה כללה:

• ארבעה סוגי מכונות: מרכזי עיבוד 5 צירים, מסובים טיפוס סוויסי, מכונות רב-משימות, ומכונות כרסום דקיקות

• חומרים תעופתיים: טיטניום 6Al-4V, Inconel 718, אלומיניום 7075, וחומרים מרוכבים פחמתיים

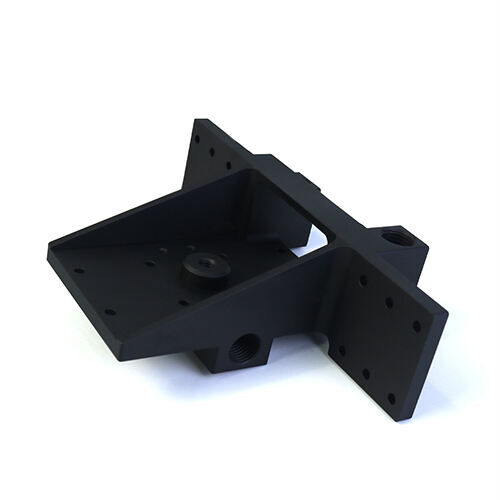

• רכיבי בדיקה סטנדרטיים: תושבות מבניות, להבי טורבינה, גלילי מניעים, וחיזוקים

• ציוד מדידה: CMM עם רזולוציה של 0.001 מ"מ, מדדי ח Roughness, ו 비교ים אופטיים

3. פרוטוקול בדיקה ויכולת חזרתיות

הבדיקות הסטנדרטיות הבטיחו איסוף נתונים עקבי:

• כל מכונה ייצרה חמישה רכיבי בדיקה זהים מכול חומר

• פרמטרי חיתוך עוקבים בהמלצות יצרן הכלים ליישומים באווירונאוטיקה

• תנאי סביבה נשמרו על 20±1°מ עם רטיבות של 45-55%

• כל הכלים, תבניות והנהלי מדידה מתועדים בנספח

תוצאות וניתוח

1. דיוק מיקום וחזרתיות

השוואת ביצועים ממדיים בין סוגי מכונות

| סוג מכונה | דיוק מיקום (מ"מ) | דיוק נפחי | חזרתיות (מ"מ) |

| מרכז עיבוד 5 צירים | ±0.005 | 0.015 | ±0.0025 |

| מכונה רב-תכליתית | ±0.006 | 0.018 | ±0.003 |

| סיבך מסוג שוויצרי | ±0.004 | N/A | ±0.002 |

| בורר מדוייק עם עיגון | ±0.003 | 0.008 | ±0.0015 |

בעוד שמסבי הקטבים הפגינו דיוק מוחלט גבוה יותר, הגיוון המוגבל שלהם הגביל את היישום לסוגי רכיבים מסוימים. מכונות חמישה צירים סיפקו את השילוב הטוב ביותר של דיוק וגמישות לגאומטריות מורכבות של תעשיית התעופה.

2. גימור שטח והיכולת הגאומטרית

מרכזי עיבוד חמישה צירים הגיעו לגימור שטח של Ra 0.4μm על פני שטחים מעוקלים, טוב יותר מההגדרות האחרות עבור גאומטריות 3D מורכבות. הסיבכים מסוג שוויצריים הצטיינו בייצור רכיבים בקוטר קטן (3-20 מ"מ) עם גימור Ra 0.2μm, במיוחד ליישומים במערכות הידראוליות ובדלק.

3. מדדי יעילות ייצור

המכונות הרב-תכליתיות הפחיתו את זמן העיבוד הכולל ב-25%-40% לרכיבים סיבוביים מורכבים על ידי ביטול פעולות משניות. עבור רכיבים מבניים הדורשים חיקוק עקום מורכב, המכונות בחמשה צירים הפגינו קצב הסרה של חומר מהיר יותר ב-30% בהשוואה להגדרות שלושה צירים.

דיון

1.פירוש ביצועים טכניים

הביצועים המעולים של מרכזי עיבוד שבבי בעלי חמישה צירים נובעים מיכולתם לשמור על כיוון אופטימלי של הכלים לאורך מסלולי עיבוד מורכבים. יכולת זו ממזערת את סטיית הכלים, משפרת את פינוי השבבים ומאפשרת תנועת חיתוך רציפה - כולם גורמים קריטיים עבור חומרי תעופה וחלל. דרישות ההתקנה המופחתות עבור רכיבים מורכבים משפרות עוד יותר את הדיוק על ידי מזעור שגיאות מיקום מחדש של חומר העבודה.

2.מגבלות ומגבלות מעשיות

המחקר התמקד ברכיבים סטנדרטיים של תעשיית התעופה; יישומים מיוחדים עשויים להניב תוצאות שונות. גורמים כלכליים, הכוללים השקעה ראשונית, עלויות תחזוקה ודרישות כישורים של המפעיל, לא כלולו בהערכה הטכנית הזו. בנוסף, המחקר הניח תחזוקה וכיול מתאימים של המכונה בהתאם לדרישות היצרן.

3.הנחיות לבחירת יישומים בתעשיית התעופה

בהתבסס על הממצאים, מומלץ להיעזר במסגרת הבחירה הבאה:

• רכיבים מבניים עם קווי מתאר מורכבים: מרכזי עיבוד 5 צירים

• חלקים סובבים קטנים ומדוייקים: מכונות טorno מסוג שוויצרי

• רכיבים סובבים מורכבים עם תכונות טחינה: מכונות רב-משימות

• דפוסי חורים בעלי דיוק גבוה ועבודות ג'יג: בוררים Präzisionsיים

בחירת המכונה אמורה גם לקחת בחשבון את מאפייני החומר הספציפיים, כאשר למכונות חמישה צירים יש יתרונות מיוחדים בחומרים קשיחים לעיבוד כמו Inconel וטיטניום.

סיכום

מרכזי עיבוד חמישה צירים מייצגים את הפתרון הרב-תכליתי ביותר לרוב רכיבי התעופה והחלל בעלי הדיוק המדויק, ומאפשרים דיוק מיקום של ±0.005 מ"מ תוך טיפול בצורות גאומטריות מורכבות וחומרים קשים. מכונות רב-משימות מספקות יתרונות משמעותיים ביעילות לרכיבים הדורשים גם סיבוב וגם עיבוד פילם, בעוד מכונות טorno מסוג שוויצרי נשארות חסרי תחרות לרכיבים קטנים בקוטר. יצרנים צריכים לבסס את בחירת הציוד על מאפייני הרכיב הספציפיים, נפחי הייצור ודרישות החומר, כאשר טכנולוגיית חמשת הצירים משמשת כבסיס ברוב מתקני הייצור המודרניים בתעשיית התעופה והחלל. מחקר עתידי אמור לבחון את אינטגרציה של יכולות ייצור תוספות (additive manufacturing) ואת מערכות ניטור מתקדמות כדי לשפר עוד יותר את הדיוק והיעילות.