News & Blog

-

A new process for machining heat-resistant alloy parts has reduced tool wear by 15%.

A New Process for Machining Heat-Resistant Alloy Parts Has Reduced Tool Wear by 15% When machining tough alloys feels like cutting through fire I still remember the sound — that sharp, grinding noise when a carbide insert meets Inconel 718 at h...

Oct. 28. 2025 -

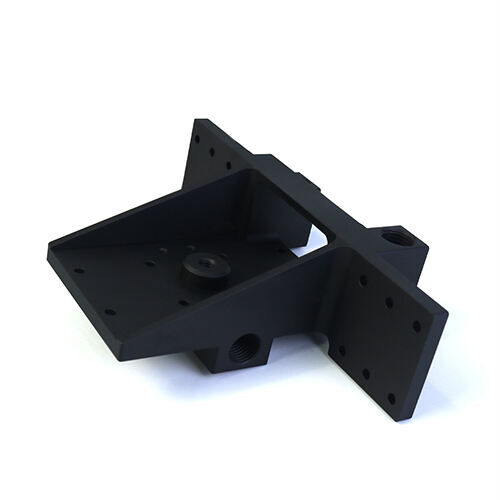

3C electronic product housing machining

3C Electronic Product Housing Machining: Integrated High-Gloss Surface and Structural Design When I first ran my hand across a freshly milled 3C electronic housing — its surface gleaming like glass, edges perfectly aligned — I knew we&rsq...

Oct. 27. 2025 -

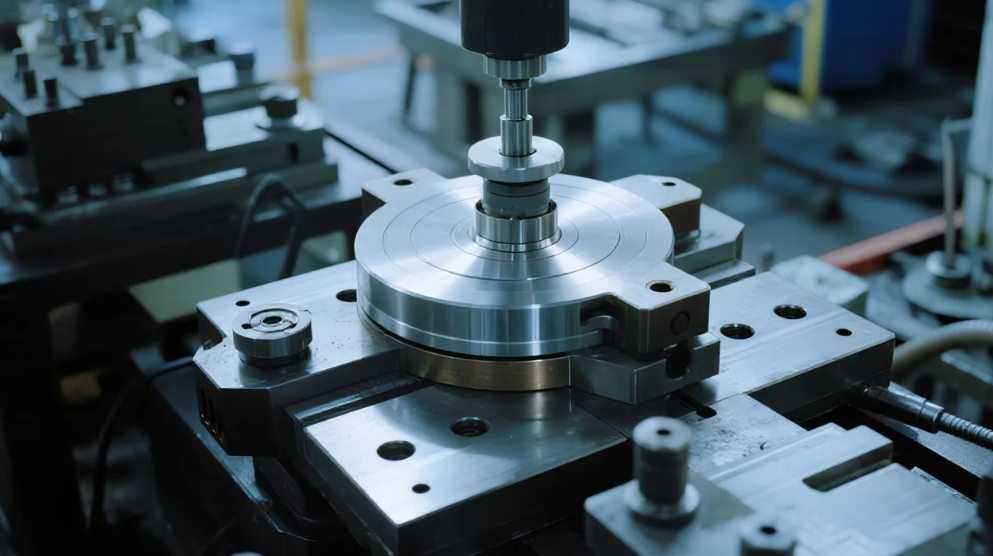

Which CNC Machine is Best Suited for High Precision Aerospace Components?

The aerospace industry's relentless pursuit of lighter, stronger, and more reliable components places extraordinary demands on manufacturing equipment. With tolerances routinely exceeding ±0.025mm and materials ranging from aluminum alloys to ...

Oct. 24. 2025 -

Is CNC Cutting Expensive? A Data-Driven Cost Analysis

The perception of CNC cutting as an expensive manufacturing method often overlooks the comprehensive cost-benefit analysis that includes material efficiency, precision quality, and reduced secondary operations. As manufacturing evolves in 2025, under...

Oct. 23. 2025 -

What is a CNC Prototype?

In today's competitive manufacturing landscape, the ability to rapidly transform concepts into tangible components separates industry leaders from followers. CNC prototyping has emerged as the gold standard for pre-production validation, offering unp...

Oct. 17. 2025 -

How Much Does It Cost to Get Something CNC Machined?

For engineers, product developers, and procurement specialists, understanding CNC machining costs remains challenging due to the numerous variables involved. In 2025, with global manufacturing becoming increasingly competitive and customized, accurat...

Oct. 16. 2025 -

What Industries Need CNC Machining?

As global manufacturing evolves toward higher precision and digital integration, CNC machining has transitioned from a specialized tool to a fundamental industrial capability. While numerous industries utilize CNC technology, significant differences ...

Oct. 14. 2025 -

Is CNC Machining in High Demand?

As global manufacturing evolves through rapid technological advancement, questions arise regarding the continued relevance of established processes like CNC machining. While some speculate that additive manufacturing may replace subtractive methods, ...

Oct. 13. 2025 -

How much does it cost to get something CNC machined?

The high-pitched whir of the spindle cuts through the air, metal chips scatter across the floor, and when I pick up the freshly cut part, the surface still feels warm to the touch. That’s the moment you realize: every detail, from t...

Sep. 27. 2025 -

What type of manufacturing is machining?

The moment the spindle starts spinning, you can almost feel the vibration through the floor, hear the sharp hum of the cutting tool, and smell that faint scent of freshly cut metal. I still remember the first time I stood next to a CNC lathe (a compu...

Sep. 26. 2025 -

What is meant by CNC cutting?

What is Meant by CNC Cutting? | A Practical Guide Introduction Imagine standing on a factory floor: the steady hum of machines, the scent of freshly cut aluminum, and sparks flying as a sheet of metal is transformed into a precise component. This tra...

Sep. 25. 2025 -

Pipe Adapters: The Unsung Heroes of Your Plumbing and Industrial Systems

Pipe adapters remain one of the most overlooked yet essential components in fluid transport systems. As we move through 2025, increasing system complexity and higher performance demands make proper adapter selection more critical than ever. This arti...

Sep. 25. 2025