Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

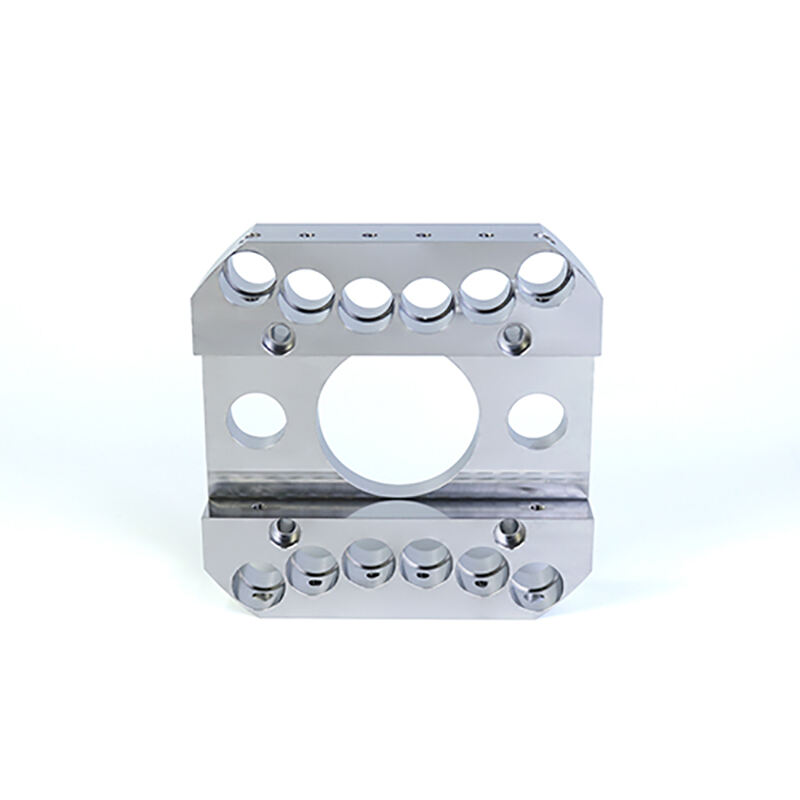

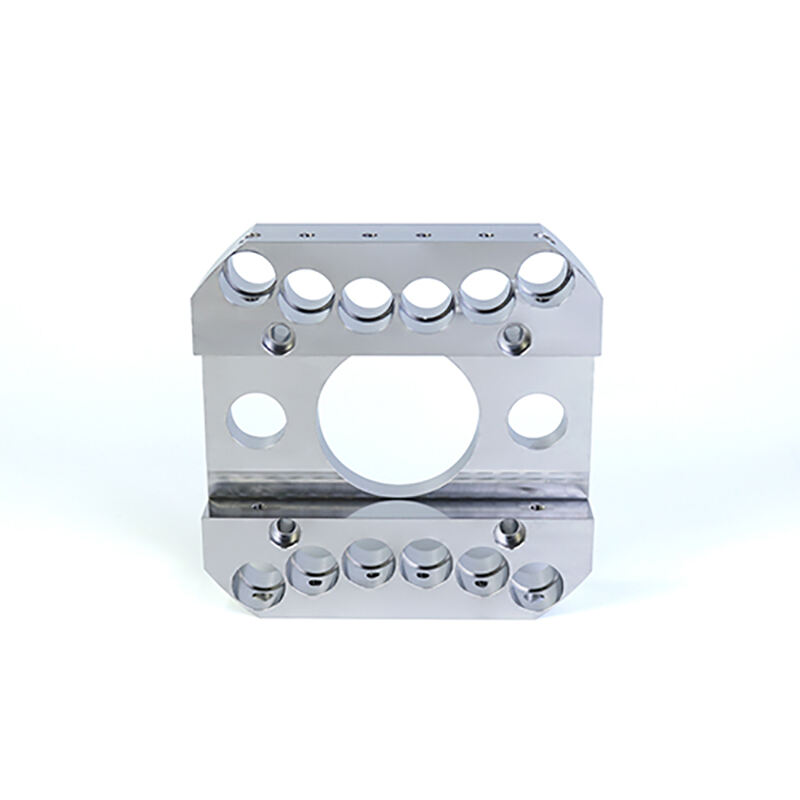

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In today's manufacturing landscape, precision is everything. From aerospace components to medical devices, the need for accuracy, reliability, and quality control has never been more crucial. Precision fabrication services have emerged as a cornerstone of modern machining offering unparalleled benefits to industries that demand the highest standards of manufacturing.

Precision fabrication services refer to specialized machining processes that create components and parts with tight tolerances and superior accuracy. Unlike standard machining, which may focus on efficiency and volume, precision fabrication emphasizes exact measurements, intricate designs, and minimal deviation from specified dimensions. These services often involve a combination of computer-controlled equipment, advanced materials, and skilled craftsmanship to achieve results that meet or exceed client specifications.

The term "precision fabrication" covers a wide array of processes, including CNC (Computer Numerical Control) machining, laser cutting, EDM (Electrical Discharge Machining), sheet metal fabrication, welding, and more. These processes are designed to achieve parts that are not only functional but also durable and high-performance, even under extreme conditions.

1.CNC Machining

CNC machining is one of the most popular methods for precision fabrication. It involves the use of computer-controlled machines to cut, mill, drill, or turn materials like metal, plastic, and composite materials with high precision. CNC machines can operate on multi-axis configurations, allowing them to perform complex tasks with incredible accuracy.

2.Laser Cutting

Laser cutting involves using a high-powered laser beam to cut through materials with precision. It is especially effective for cutting thin materials like sheet metal, plastic, and ceramics. Laser cutting provides a clean edge with minimal distortion, which is ideal for parts that need to fit together perfectly or require intricate patterns.

3.Electrical Discharge Machining (EDM)

EDM is a process that uses electrical discharges or sparks to remove material from a workpiece. It is often used to create precise and intricate features in hard metals that are difficult to machine using traditional methods. EDM is widely used in tool and die making and can create sharp internal corners and holes that would be impossible with standard cutting tools.

4.Welding and Assembly

For some precision fabrication needs, welding is an essential process. Whether using MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or other specialized welding techniques, precision welding ensures the integrity and durability of parts. High-precision welding is often required in industries like aerospace and medical devices, where even the slightest structural weaknesses can have catastrophic consequences.

5.Sheet Metal Fabrication

This process involves cutting, bending, and assembling metal sheets into precise shapes. Precision sheet metal fabrication ensures that parts like chassis, frames, and enclosures are produced with exact dimensions and smooth finishes. This is particularly important in industries like electronics, automotive, and telecommunications.

The demand for precision in machining is driven by the increasing complexity of modern products. Components that once were simple and straightforward now require tight tolerances and specialized features. Here's why precision fabrication services are critical:

1.Quality Control

One of the biggest advantages of precision fabrication is the high level of quality control it offers. By adhering to strict tolerances and standards, manufacturers can ensure that the parts produced fit together seamlessly and perform at their best.

2.Reduced Material Waste

Precision fabrication minimizes the amount of excess material generated during the production process. Since the machinery and techniques used are highly accurate, there is less scrap material, which not only reduces costs but also helps make the manufacturing process more environmentally friendly.

3.Enhanced Performance

In industries like aerospace, automotive, and medical devices, precision components often translate to improved product performance. For example, parts in an aircraft engine must be manufactured with extreme accuracy to ensure proper fit and function, directly impacting the safety and efficiency of the vehicle.

4.Cost-Effectiveness

While precision fabrication services might seem more expensive initially, they often lead to cost savings in the long run. The high quality and durability of precision parts mean fewer failures, less downtime, and reduced repair costs. This is particularly important in sectors like defense and energy, where failure is not an option.

5.Customization and Flexibility

Precision fabrication services can also offer a level of customization that standard manufacturing processes cannot. Whether it's a unique part with complex geometries or a small batch of custom components, precision fabrication allows manufacturers to cater to the specific needs of clients and industries.

Precision fabrication services are used across a wide range of industries, each with its own specific needs for high-precision parts. Some of the most notable industries include:

1.Aerospace

Aerospace components often require parts to be manufactured to extremely tight tolerances. Aircraft engines, landing gear, and airframe components must be precisely fabricated to ensure safety and reliability in flight. Common materials used in aerospace precision fabrication include titanium, aluminum, and high-strength alloys.

2.Medical Devices

In the medical field, precision fabrication is crucial for creating devices like implants, surgical tools, and diagnostic equipment. These parts need to meet stringent regulations and must be free from defects. Precision machining can produce complex parts like catheter tips, prosthetics, and micro-surgical instruments, where even the smallest error can result in severe consequences.

3.Automotive

In the automotive industry, precision fabrication is essential for producing high-performance parts such as engine components, suspension systems, and transmission gears. Automotive parts must meet strict safety and quality standards while being lightweight and durable. Precision fabrication ensures that these components function optimally over time, even under extreme conditions.

4.Electronics

The electronics industry relies heavily on precision fabrication to create components like connectors, circuit boards, and housing enclosures. Parts need to be fabricated with great precision to fit within tight spaces, ensure proper electrical conductivity, and withstand the stresses of everyday use.

5.Defense and Military

The defense industry demands the highest levels of precision for manufacturing parts that are used in weapons systems, military vehicles, and communication equipment. These parts must be durable, reliable, and able to function in extreme environments, making precision fabrication an essential part of the production process.

6.Energy

Whether it's oil and gas, renewable energy, or nuclear power, the energy sector requires precision-fabricated components to ensure the smooth and safe operation of critical infrastructure. Parts like turbines, valves, and pumps must be fabricated to exact specifications to ensure efficiency and minimize the risk of failure.

Q:Why is precision important in fabrication?

A:Precision ensures that parts fit together correctly, function as intended, and meet stringent industry standards. In sectors like aerospace and medical devices, even the smallest deviation from specifications can lead to catastrophic failures. Precision fabrication helps reduce errors, improves product quality, and ensures safety and reliability.

Q:Can precision fabrication services handle both prototypes and large-scale production?

A:Yes, precision fabrication services can handle both prototypes and small-to-medium production runs. For prototypes, fabrication services are used to test designs and ensure they meet the required specifications before full-scale production. For larger production runs, services can ensure that each part is consistently manufactured to the same high standards.

Q:How does CNC machining contribute to precision fabrication?

A:CNC machining plays a central role in precision fabrication by offering unmatched accuracy and repeatability. CNC machines can create complex geometries, multi-dimensional cuts, and intricate details that would be difficult or impossible with manual tools. These machines are controlled by computer programs, ensuring that every part produced meets the exact specifications.

Q:Is precision fabrication only for metal parts?

A:No, precision fabrication is not limited to metal parts. While metals like stainless steel and aluminum are common, precision fabrication can also be used for plastics, composites, and even ceramics. Each material has its own set of fabrication techniques, and skilled fabricators can select the right method based on the material and the requirements of the project.

Q:What is the role of quality control in precision fabrication?

A:Quality control is critical in precision fabrication to ensure that each part meets the exact specifications. The process typically involves:

· Dimensional Inspections: Using tools like micrometers, calipers, and CMM (Coordinate Measuring Machines) to measure parts and ensure they meet tolerances.

· Visual Inspections: Checking for defects, surface finish quality, and other visible imperfections.

· Testing: For some applications, parts may undergo stress testing, fatigue testing, or performance evaluations to ensure they will perform under real-world conditions.

· Traceability: Keeping detailed records of the materials, processes, and inspections for each part, ensuring that any potential issues can be traced and resolved quickly.

Q:Can precision fabrication services assist with product design?

A:Yes, many precision fabrication companies offer design assistance as part of their services. This can include:

· CAD (Computer-Aided Design) Support: Helping clients refine their designs to ensure they are manufacturable and cost-effective.

· Material Selection: Offering advice on the best materials for performance, cost, and manufacturability.

· Prototyping: Creating prototype parts to test designs before moving to full-scale production.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog