Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

When you need parts that match exact specifications, your go‑to solution should be factory customized CNC milling and turning parts.At our advanced facility, we turn digital designs into precision parts with the speed, accuracy, and quality modern engineers demand.

We offer end-to-end factory customized services where CNC milling and turning parts are crafted to your exact engineering requirements. Whether you need a complex milled geometry or a turned shaft with tight tolerances, our machines deliver:

• Tight tolerance control (e.g. ± 0.005 mm or ± 0.0005 in) using multi-axis milling and precision lathes .

• Surface finishes, threading, grooving, and wall thickness designed per your spec sheet .

• Material flexibility across aluminum, stainless steel, brass, nylon, POM, PEEK, and more, selected based on performance or cost.

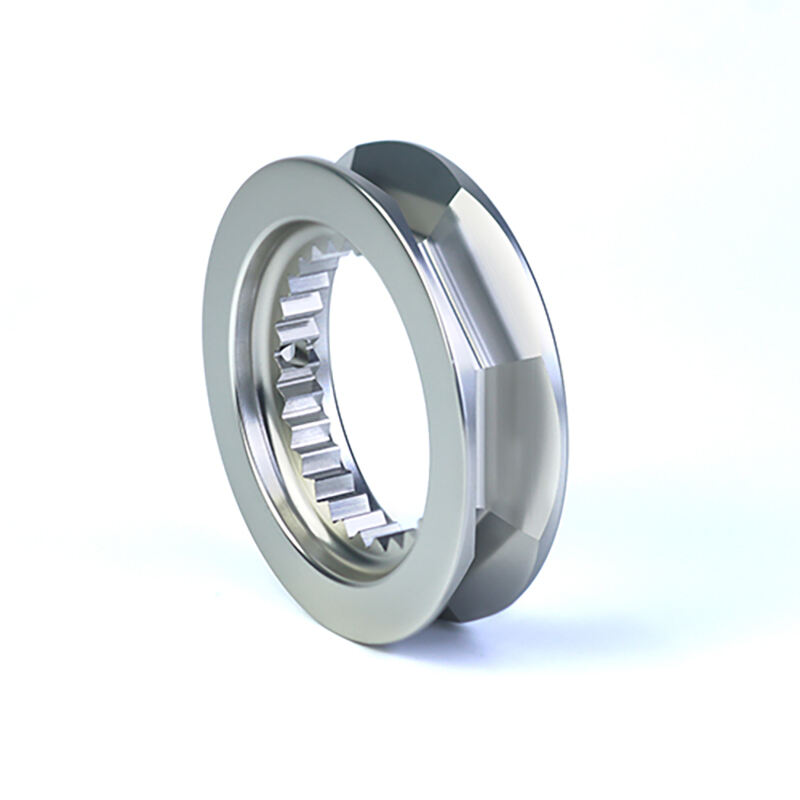

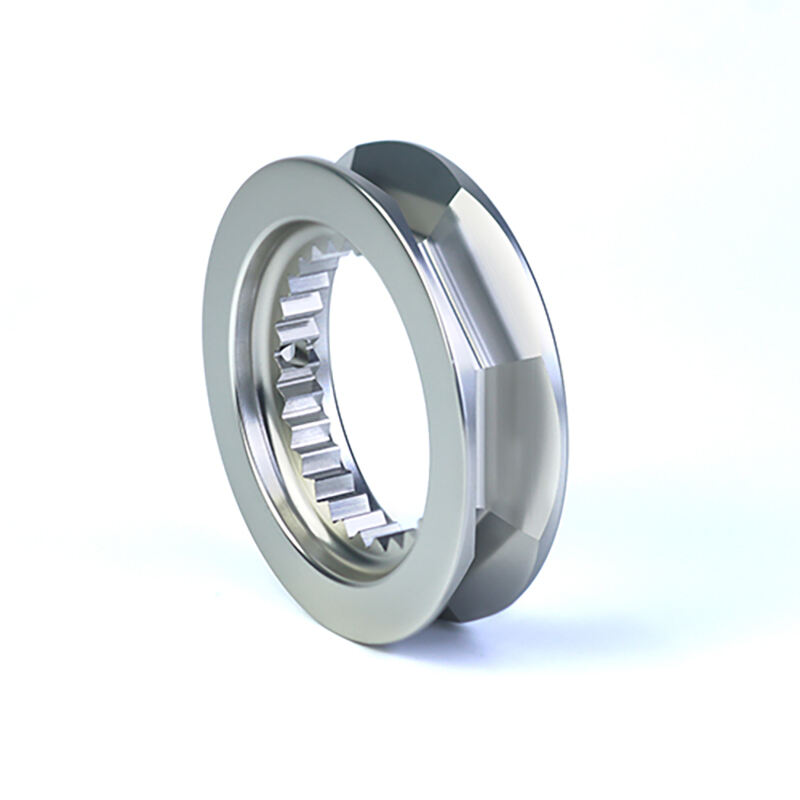

• CNC milling parts: Ideal for shapes with pockets, slots, or complex faces. Tools are controlled in multiple axes, removing material from solid blocks.

• CNC turning parts: Best for round profiles—shafts, bushings, collars—where the workpiece rotates against a fixed tool.

When combined in a factory-customized workflow, milling and turning capabilities let us deliver mixed-geometry parts with complex features more efficiently and cost-effectively.

Clients across automotive, aerospace, robotics, and medical industries rely on our CNC milling and turning parts for:

• Precision gears, shafts, and spacers.

• Custom housings and instrument components.

• Robotic mounts with machined surfaces and built‑in grooves.

• Medical-grade parts with specific surface finish and biocompatible materials.

If your project calls for precision, reliability, and customization, our factory model delivers custom CNC milling and turning parts just the way you need them. From design input and DFM optimization, through to rapid prototyping or scaled production, you get exact-fit parts made efficiently.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog