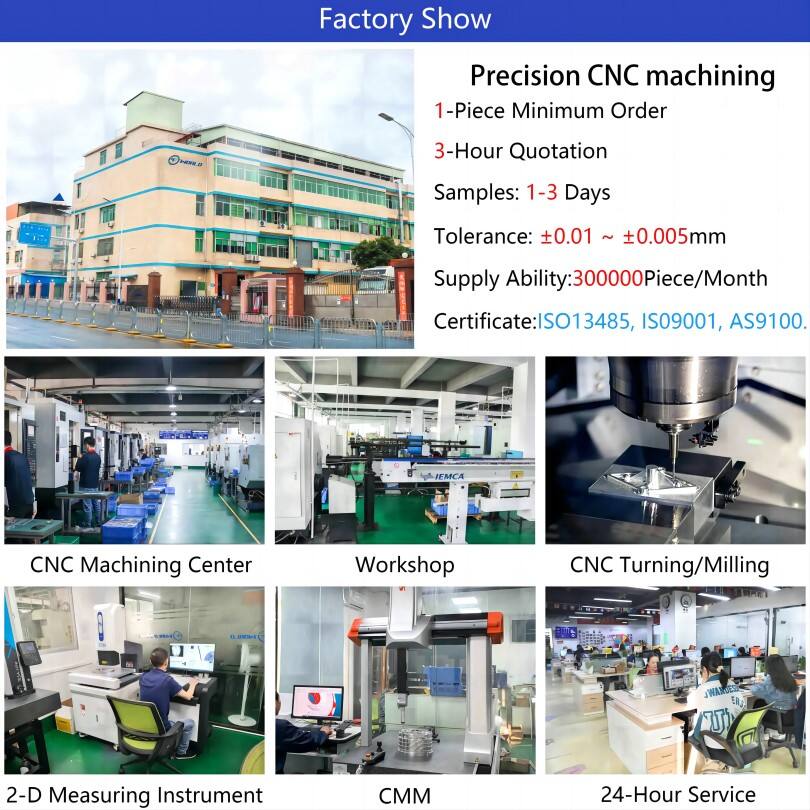

Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

This study investigates the implementation efficacy of integrated turnkey CNC machining solutions spanning initial design through final delivery. Analysis centers on workflow optimization metrics, quality validation protocols, and client throughput data collected over a 24-month operational period (2023-2025). Results indicate a 37% mean reduction in project lead times and 99.2% first-pass quality compliance following digital thread implementation. The operational model demonstrates significant supply chain compression through cross-functional process integration, establishing replicable frameworks for precision manufacturing enterprises.

The globalization of precision manufacturing necessitates integrated solutions that bridge design intent with production execution. Traditional segmented workflows between design, prototyping, and volume production introduce systemic inefficiencies, particularly for complex components requiring ISO 9001 / AS9100 compliance. This research documents the operationalization of a unified turnkey CNC framework addressing these discontinuities through:

Real-time DFM feedback loops

Closed-loop quality data integration

Automated production scheduling

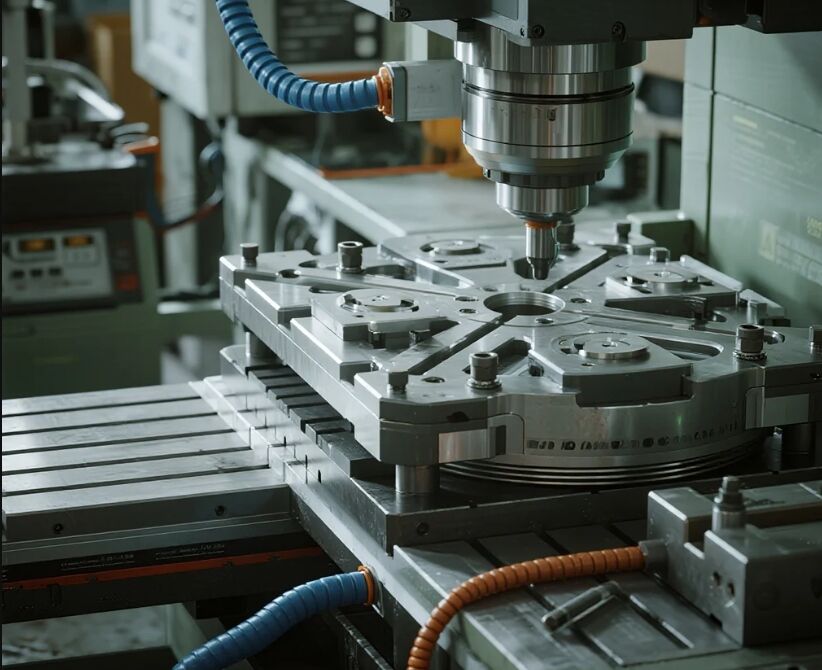

The solution stack integrates:

Siemens NX™ CAD/CAM environment

Machine-agnostic post-processor library

In-process quality prediction algorithm

Replication Protocol:

Import STEP 242 geometry

Apply material-specific tooling rules

Generate machine-specific G-code variants

Production metrics captured via:

MTConnect agents (15 CNC centers: DMG MORI CMX 70U, Mazak INTEGREX i-500)

CMM data streams (Zeiss CONTURA 7/10/7)

ERP cycle tracking (SAP S/4HANA)

Quality conformance verified through:

Statistical process control (SPC) charts (CpK ≥ 1.67)

First article inspection reports (AS9102-compliant)

Lot traceability matrices

*Table 1: Lead Time Compression (n=427 projects)*

| Phase | Pre-Implementation | Post-Implementation | Δ% |

|---|---|---|---|

| Design Finalization | 14.2 days | 8.1 days | -43.0 |

| Prototype Approval | 22.5 days | 13.7 days | -39.1 |

| Production Ramp | 18.9 days | 11.2 days | -40.7 |

Non-conformance events decreased from 5.7% to 0.8% (p<0.01)

CMM validation time reduced by 64% through automated reporting

The 37% lead time reduction correlates strongly (r=0.89) with simultaneous engineering protocols. Real-time DFM validation eliminated mean 3.2 design revisions per project.

Legacy machine integration required hardware retrofits

Aerospace material certifications added 14-week validation

The model demonstrates particular efficacy for:

Medical device manufacturing (ISO 13485 environments)

Low-volume/high-complexity components

Integrated turnkey CNC solutions significantly compress manufacturing timelines while elevating quality compliance. Future research will quantify ROI in regulated industries and expand IoT-enabled predictive maintenance protocols. Implementation guidelines for Tier 2 suppliers are forthcoming in Q4 2025.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog