News & Blog

-

The Ultimate Guide to 2mm Thick High Modulus Carbon Fiber Plates: Specs, Uses & How to Choose

If you’re searching for a 2mm thick high modulus carbon fiber plate, you’re likely an engineer, product designer, or maker working on a project where every gram and every newton-meter of stiffness counts. You’re not just looking for...

Dec. 19. 2025 -

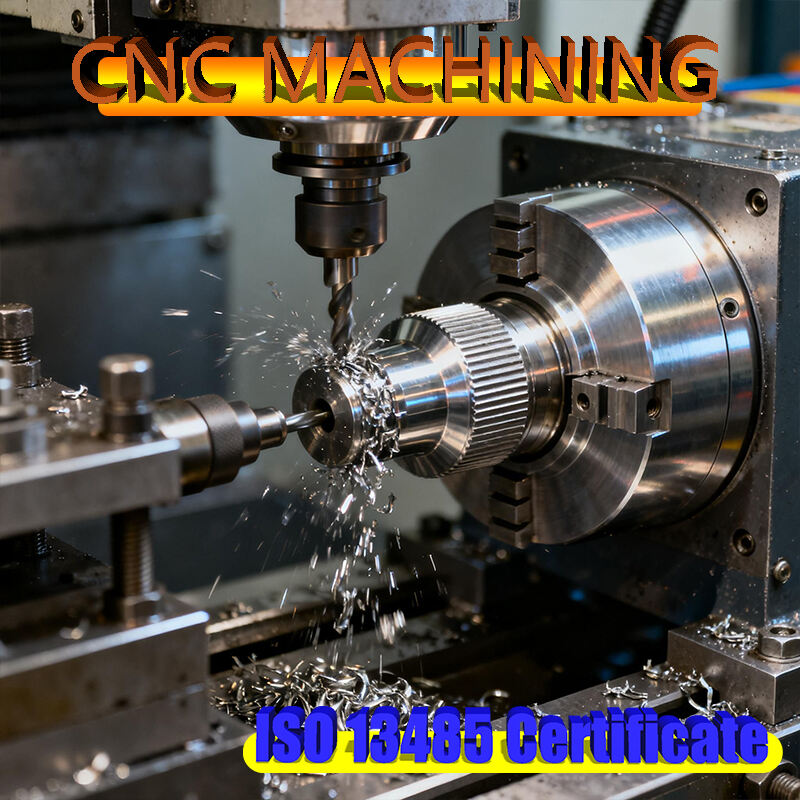

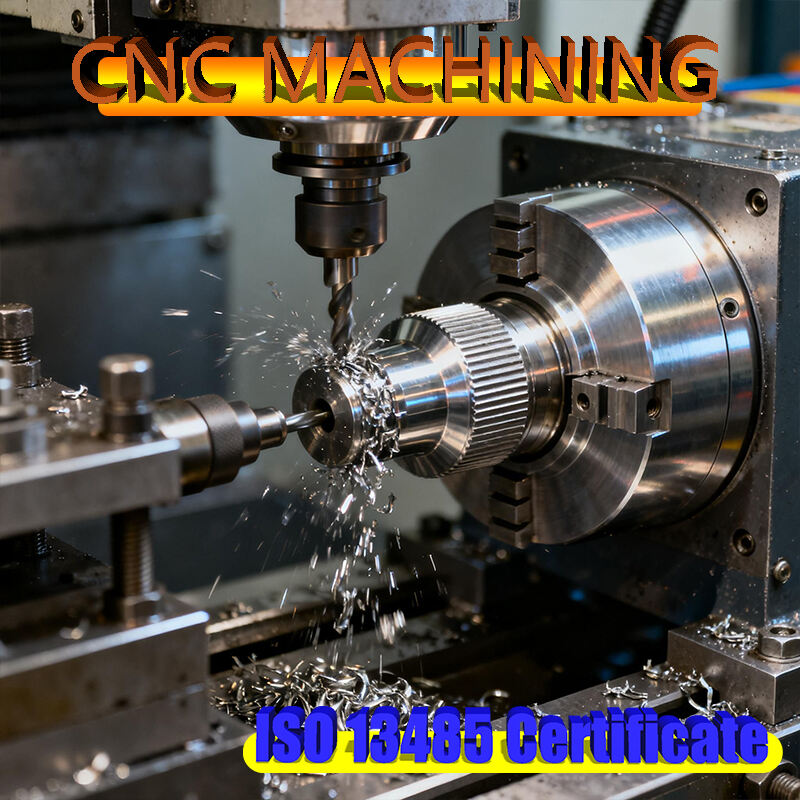

What to Check Before Ordering CNC Custom Precision Parts From Suppliers

A Real-World Factory Scenario When I first ordered CNC custom precision parts for our assembly line, the sound of machines humming in the workshop reminded me how critical each part’s accuracy is. One misaligned gear or improperly milled bracke...

Dec. 30. 2025 -

CNC Custom Precision Parts Selection Tips for Cost-Effective Procurement

Real-World Factory Scenario As I walked through the humming factory floor, the steady buzz of CNC machines filled the air, accompanied by the faint metallic scent of freshly machined parts. Each component glided out with precise tolerances, yet behin...

Dec. 29. 2025 -

New Methods for Inspecting CNC Custom Precision Parts With Higher Accuracy

Real-World CNC Inspection Scenario When I first started inspecting CNC custom precision parts in our factory, I noticed slight deviations in tolerances that could cause assembly issues downstream. The hum of milling machines, the metallic scent of al...

Dec. 27. 2025 -

How CNC Custom Precision Parts Improve Factory Output

The rhythmic hum of CNC machines fills the workshop, accompanied by the metallic clinks of cutting tools shaping raw materials. I can feel the vibration through the workbench as components are milled to micron-level precision. In this environment, ev...

Dec. 19. 2025 -

How to Choose CNC Custom Precision Parts for Tight-Tolerance Projects | A Practical Buyer’s Guide

1. Understand the True Tolerance Requirement (Not the Drawing Alone) H2 – Why Tight Tolerance Doesn’t Always Mean Expensive In many projects, buyers request ±0.01 mm as default—yet during actual assembly, the mating parts oft...

Dec. 12. 2025 -

What Are the Steps in the CNC Process?

As computer numerical control (CNC) technology continues to evolve through 2025, understanding the systematic workflow from design to finished component becomes increasingly critical for manufacturing efficiency and quality assurance. While CNC machi...

Nov. 22. 2025 -

Key Features of Precision Turned Components Factories

The manufacturing landscape for precision turned components has evolved significantly through 2025, with leading factories demonstrating capabilities far beyond basic CNC turning operations. These facilities represent the convergence of advanced manu...

Nov. 21. 2025 -

How Precise Can CNC Machines Be?

The pursuit of precision in CNC machining represents one of the most significant challenges in modern manufacturing, with implications spanning from medical implants to aerospace components. As manufacturing requirements continue to advance through 2...

Nov. 19. 2025 -

China CNC Machining Prototype: Custom Parts & Rapid Manufacturing

The landscape of CNC machining prototyping in China has undergone remarkable transformation, emerging as a critical enabler for global product development cycles. As we progress through 2025, China's prototype manufacturing sector demonstrates unprec...

Nov. 16. 2025 -

CNC Machining Surface Finishes Explained: Anodizing, Sandblasting, Passivation, Polishing

1 Research Methods 1.1 Design Framework The evaluation follows a controlled comparative design. All test parts were CNC-machined from 6061-T6 aluminum and 304 stainless steel using identical cutting parameters to maintain consistent baseline roughnes...

Nov. 29. 2025 -

Understanding CNC Machining Tolerances (GD&T Basics + Real Factory Examples)

Understanding CNC Machining Tolerances (GD&T Basics + Real Factory Examples) When engineers talk about “precision,” they often refer to tolerances—but the truth is, tolerance requirements vary massively depending on part geometr...

Nov. 27. 2025